the S uses 350 in the front and 275 in the rear... your shocks are supposed to be red too for an "R"

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

I'm going to wait before trying to design the upper control arm spacer. I need to be looking at it.

I'm going to wait before trying to design the upper control arm spacer. I need to be looking at it.

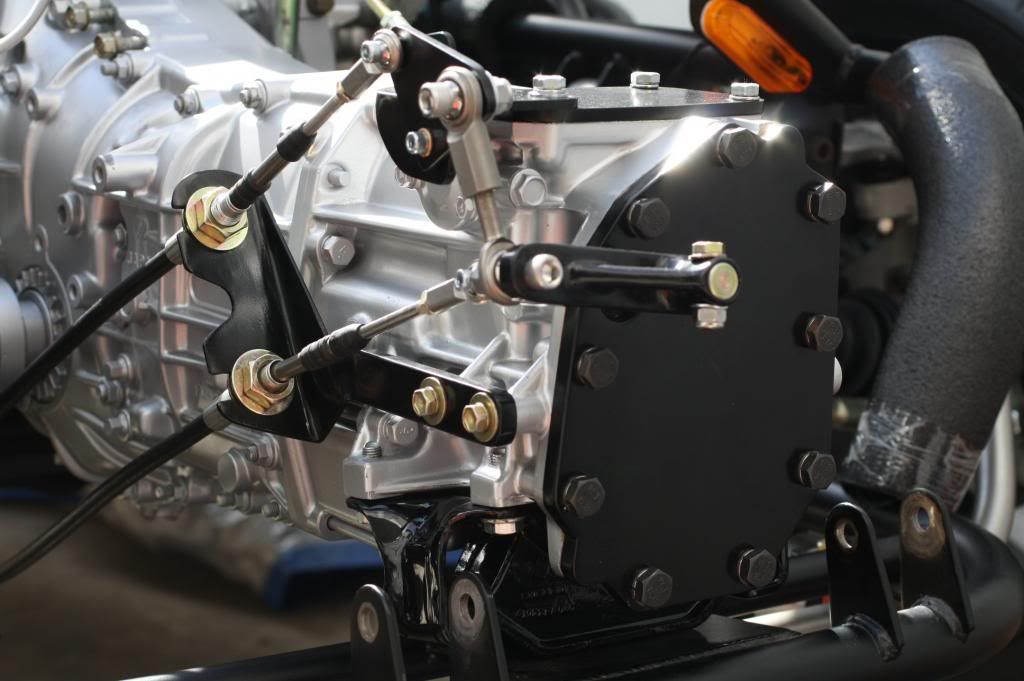

time to make it rain! (sparks)

time to make it rain! (sparks)