After some reading I think the MXS Strada will be the way to go. I don't need it yet, lots to do, and for initial startup a laptop will suffice. When the time comes Wayne, I'll contact you about a price.

So I finally put this thing on the ground, and "shut the front door" this thing is low!!! Does everyone just get blown away by that the first time? It's been two days and I still can't believe it when I go out in the garage.

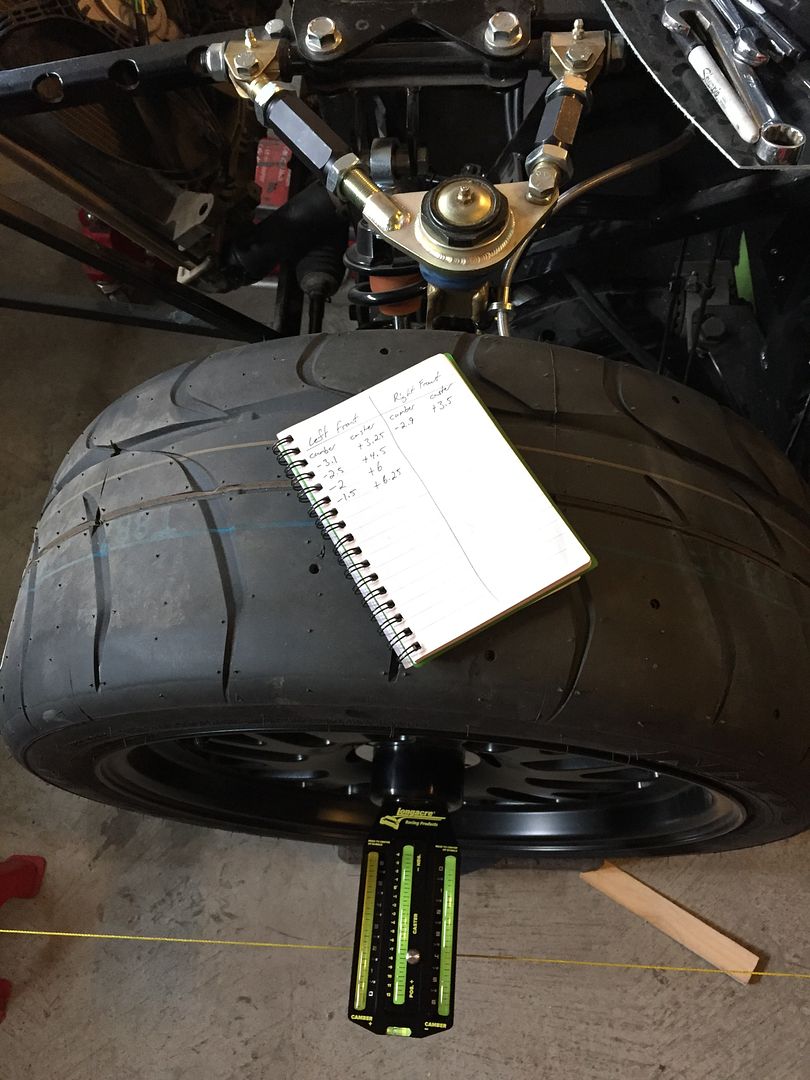

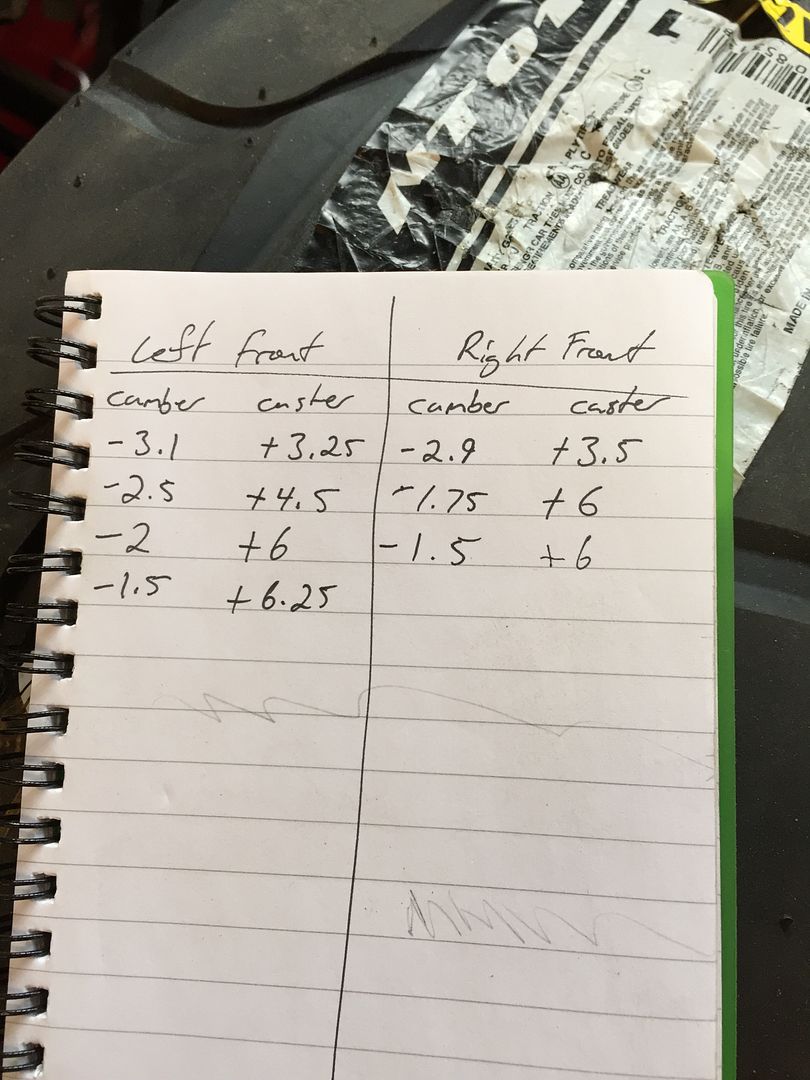

So I rolled it out in the driveway to start my rough alignment. My garage has a drain in the middle so it's very uneven, everything sits on 3 jack stands. My driveway is perfectly level side to side a an even 3.8 degree slope. Great for adjusting toe, no good for caster, but in my head it should work for camber if the wheel is strait and the chassis and ground are level side to side. However I'm showing -3 degrees front camber before I start adjusting, which from what I've been reading should be impossible. It does however visibly look quite cambered.

Also, does anyone else have a taller rear tire then the front? My fronts measure at 25" and my rears at 26", so should I rake the chassis a 1/2"? Since they're taller than most, I figured I should set ride a little higher so the suspension rests where it should. And adjusting ride height is a huge PITA with the wheels on, but it would take forever to take them on and off a dozen times since there's no way of knowing how much to spin them for the desired drop. My current ride height is 5.375" front and 5.875" rear. To get the rear that low the spring collar had to be lowered about 1/2" from Wayne's recommended preload. I'm guessing a combination of tall tire and lighter engine(with turbo off too).

As always, thoughts and comments are welcome.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote