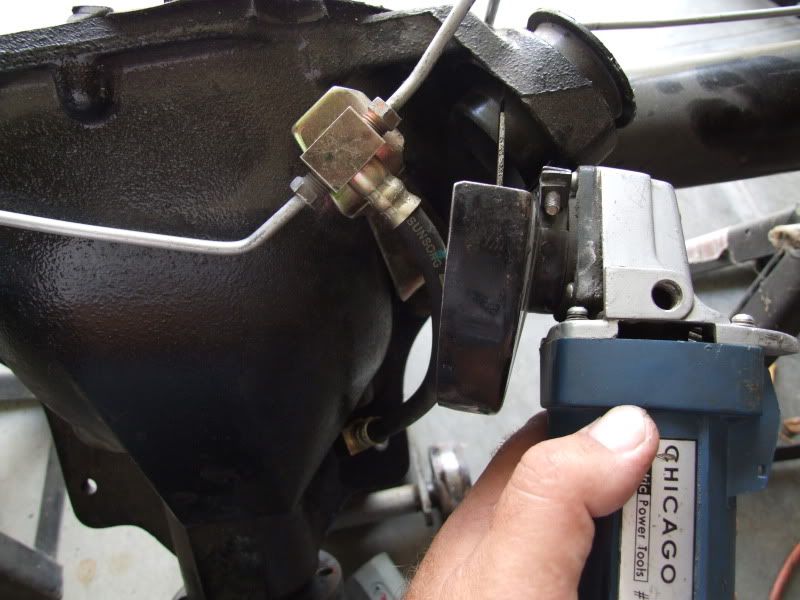

Check out the pics from post 38. That is where I am using the UCA flanges that I cut. They will mate to the bushings so it should be a perfect fit (with a little spreading). I also wanted to use them to reduce fab time and add a little dampening to the system. It will have less than the 4 bushing 4 link but still some. The chassis bracket will be mounted steel to steel. So I was planning on using the spherical rod ends. Don't want any binding in the system. I may do rod ends on at least one end of the lower control arms later. That would also give some alignment adjustment if needed. Thanks for the additional Afco source. I have been using Speedway but I will check around.

Regarding the length of the upper third link: I do have concerns about that. However, the 4 link has been operational on my roadster and works fine. I don't experience any pinion angle issues. So I am thinking the similar length link should work. I will do my best to extend the length of that. I think I might fudge a little and get as much as 1.5 inches. That would put it at about 11.5 inches. Mike, what is the length of your upper link? Also, FFRs third link can't be that much longer than mine since there is only a limited space to work in. I know they cheat by putting it further aft but not that much. I guess the unknown after changing links will be to make sure pinion angle is OK. I will do pics and measurements lifted and at ride height as it is now to make sure I can get back to that setting when I make the change.

I appreciate the critical thinking and input you guys give as it is, in my opinion, a real strength of this forum. It never hurts to have multiple pairs of eyes on the subject matter to get to a conclusion. I know it keeps me focused on the task at hand. Thanks again,

WEK.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote