Check out John George at speed for a few minutes before the engine grenades. This short five minute video is exciting and heart-breaking at the same time. The car is SO FAST, and it was tough for the team to fail to record a great time and a win with the car.

Racing is the best and the worst. Last Friday at VIR it was the worst. One of the many reasons Factory Fives are so good is because we are committed to racing and that commitment is really tough sometimes. Friday it was really tough.

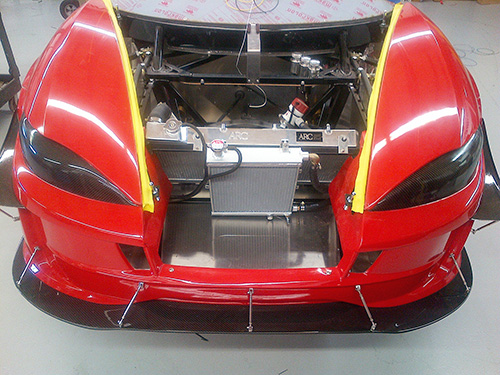

Last weekend we went to VIR (Virginia International raceway) with two race-prepped 818R’s. The goals were to get the cars down below two minutes, to test some aero changes and to continue to tune and develop the chassis. Bottom line is that 37 minutes into the day, both cars would have catastrophic engine failures. Racing breaks your heart. Losing two engines breaks your heart AND your bank account! Relatively stupid small things that combined to knock out both cars.

In the red 818R, John George was pulling 150+ mph on the straights on his WARM-UP LAPS! The car is SICK fast and totally capable of running with just about anything on the track. Sub-two minutes is obvious… John had a clamp on the turbo fail that opened up the engine to an immediate 44 lbs of boost… looks like a connecting rod went. The car had been dyno’d at 412 rwhp before we came down to VIR.

After we disassembled the car and got a closer look, we found that the red 818R had an oil leak onto the exhaust manifold that burned the timing chain cover and the hose to the external waste gate. With the hose melted, the boost spiked to 45 PSI and the engine threw a connecting rod. The engine was shut down and John coasted to a stop on the front straight away. The damage was too much to continue.

The engine block is scrap.

I drove the 345 hp blue 818R and was simply slack-jawed at the neck-straining cornering, the drive out of the turns was making me giddy and the braking made me feel like I could ignore the rules of physics… This little car is an extremely fast track car and it handles sooo good! I had spent maybe 3-4 laps getting used to it and starting to dial up the speed when near the midpoint of my first session, I had blue/white smoke coming from the rear exhaust. I shut it down and pulled off track. In the pits, we found one cylinder had lost all compression and the car was done for the weekend.

It turns out the blue 818R had a cooling line to the turbo charger loosen up at the banjo fitting, and enough coolant leaked out to over heat and seize the engine. After it cooled off, the car runs but one cylinder has no compression and it may require a new short block.

John ran a three hour endure race in a FFR Challenge car on Saturday, but the 818R’s were on the trailer. True to form, the team got to work Monday morning bright and early. The cars were unloaded and were being stripped down, engines taken out, all by 8:30am. It’s tough to lose like we did Friday but I’m proud as heck of the guys and we’ll go back and we’ll run faster than we ever dreamed.

The engine was out and ready to be shipped to the engine builder by noon on Monday.

A lot of companies brag about the track abilities of their cars. Most of em have never seen a track. From the earliest days at FFR, we’ve committed ourselves to proving our cars in racing. It’s the “Racing” in Factory Five Racing that has kept our cars honest. The 818’s that we are shipping are great in large part because of this. It took me a full day to get over the disappointment (and losses) from Friday, but this week started full of hope and excitement for the next go-out. Racing Gds take their toll, I’ve learned that. Those willing to pay will lose lots of money in the process and gain other things that are priceless. Thought you guys might like to know.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote