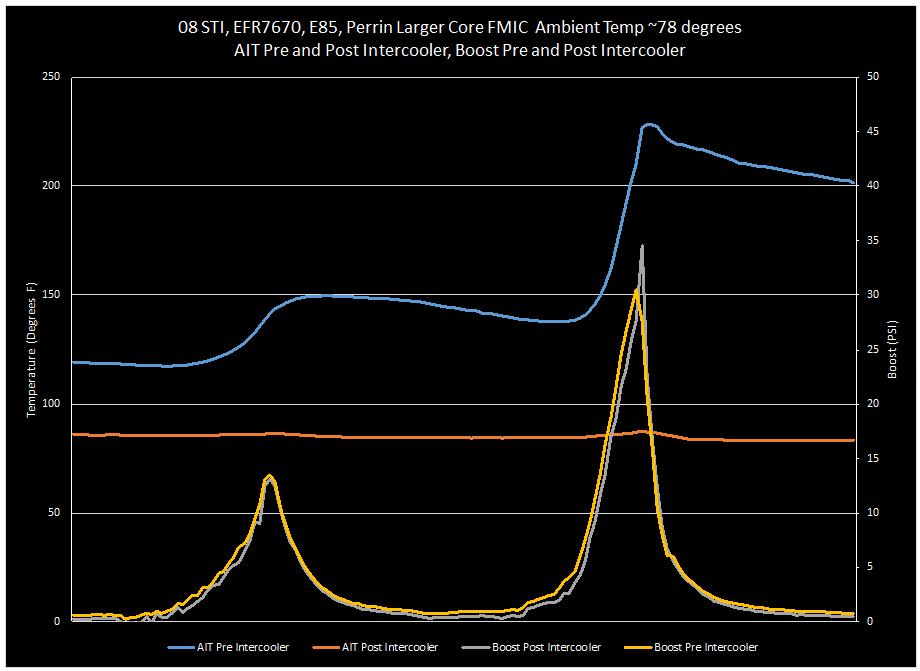

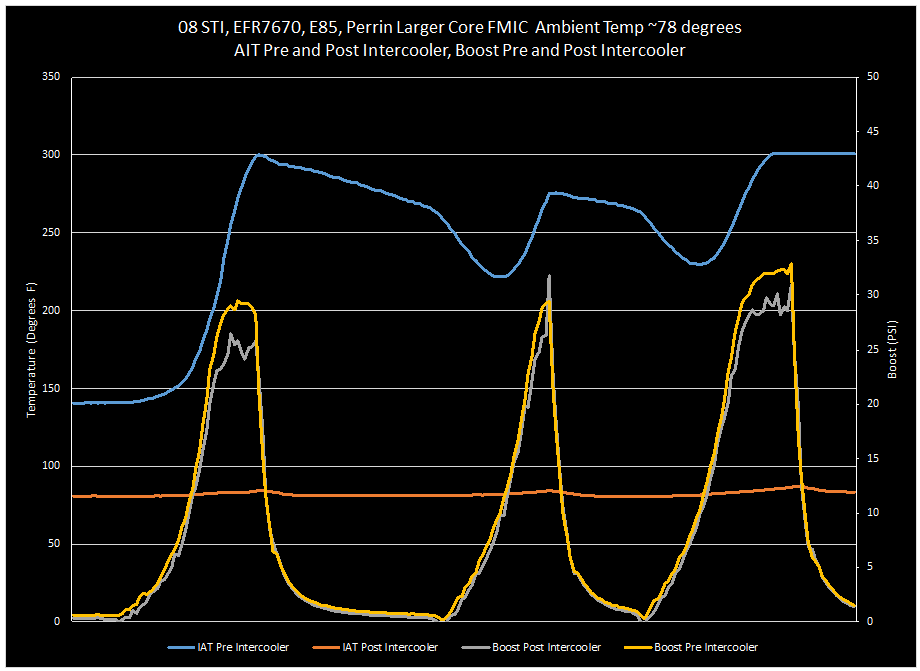

For those of you who have their cars up and running have you done any logs of intake air temperature? Have any of your relocated the IAT sensor to after the intercooler? I am researching a new intercooler design for this car and want to collect some data first.

Thanks

Tony

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

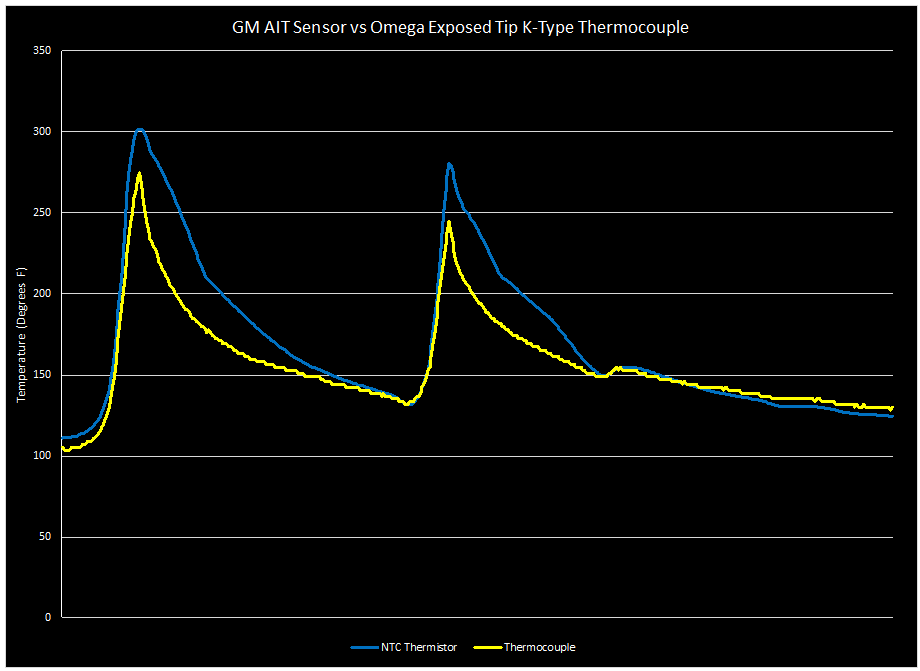

Plus, you are starting at an already too hot of temperature on the test (150 degree). I would like to see an ambient to 150 degree chart.

Plus, you are starting at an already too hot of temperature on the test (150 degree). I would like to see an ambient to 150 degree chart.