Took on the task of wiring my dash this week and so far I think, think being the key work, that I am on the right track. So I would appreciate if yall could take a look at the pictures I am going to attach and let me know if you see anything wrong, or advice, and any tips going forward. I have the FFR vintage gauges with the RF harness. I am running a Forte 347 carb, no heat or air, Speedo, tach, oil pressure, H2O temp, fuel, Voltage and a clock. I am going to wire the manual switch for the fan but am considering the auto thermostat, I also have a switch for high beams, hazard and turn signals. Also, I didn't take a picture of it but the voltmeter gauge has the daisy chain and one other wire coming out the back but I do not see any wire on the RF harness that says Volts, will this run directly from the daisy chain or do I need to use something on the RF harness.

Thanks,

Chris

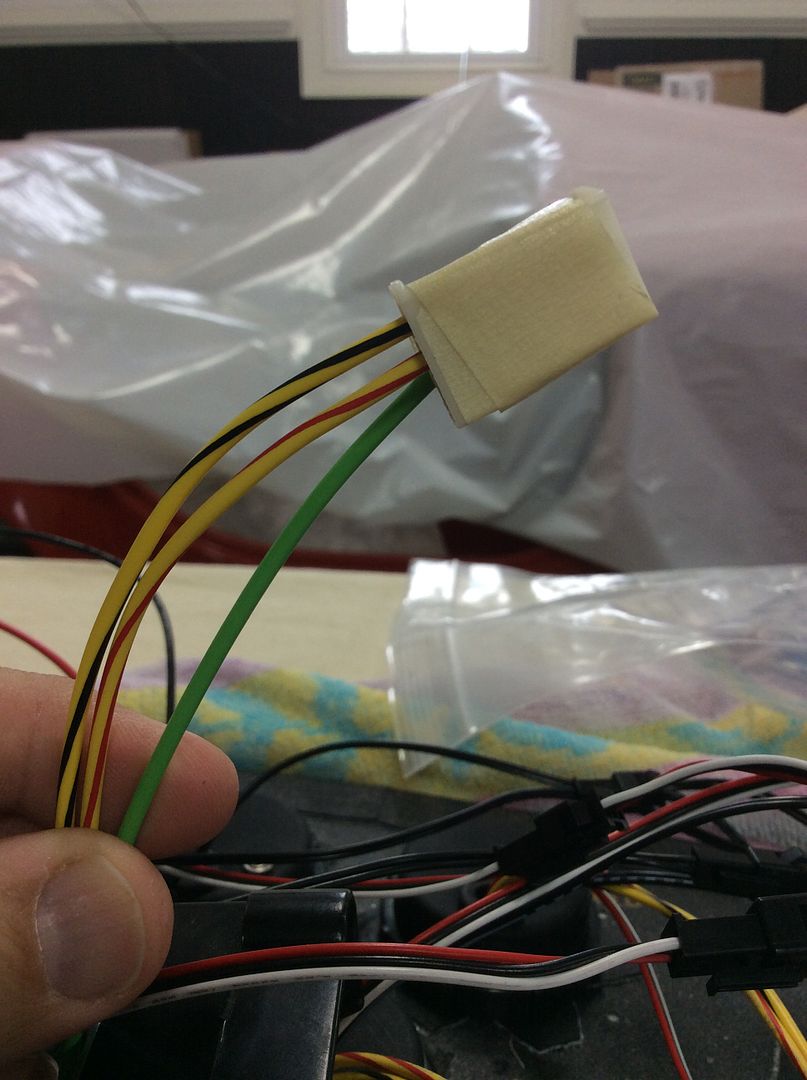

First picture is of daisy chain for the instruments, I used both daisy chains.

[IMG][/IMG]

Second pic of black daisy chain for dial lighting taped to a ground and a light wire off of the RF harness.

[IMG][/IMG]

third pic is of the red, white and black daisy taped to brown gauge feed, white light feed and ground.

[IMG][/IMG]

this pic is speedo wires, two from both the RF harness and the speedo gauge.

[IMG][/IMG]

purple tach wire from RF to Tach gauge wire

[IMG][/IMG]

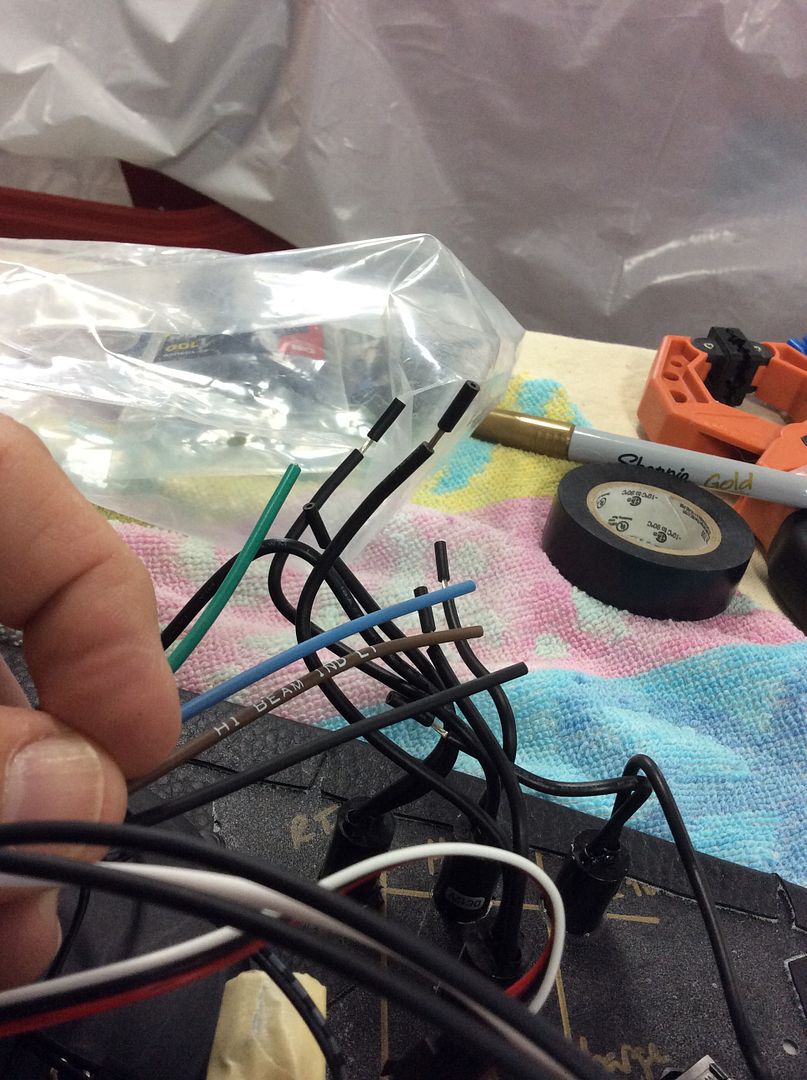

I don't know who spelled this wire but its the Water Temp to Water temp gauge. Question is there are two wires that come off the gauge?

[IMG][/IMG]

Oil pressure, again two wires off of gauge and only one RF wire

[IMG][/IMG]

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote