- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

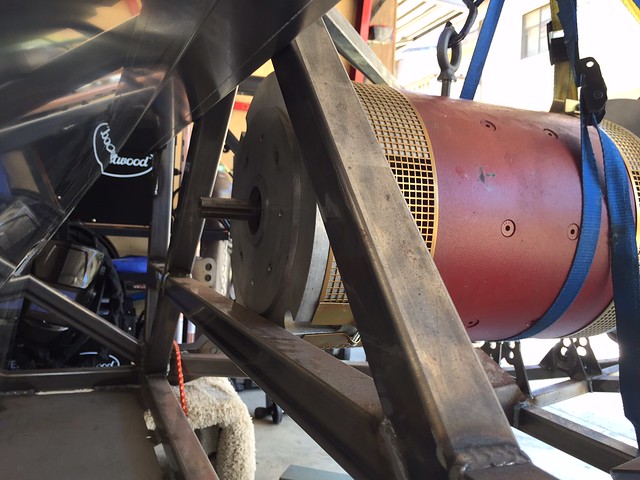

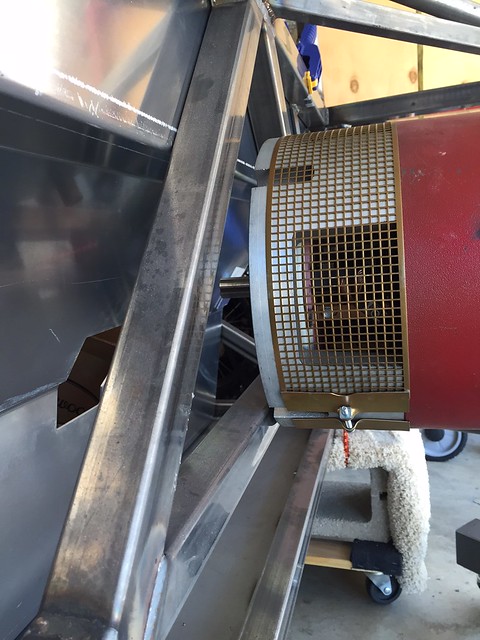

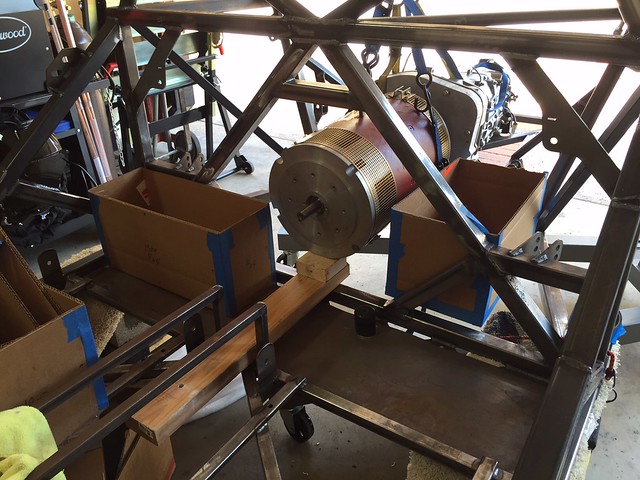

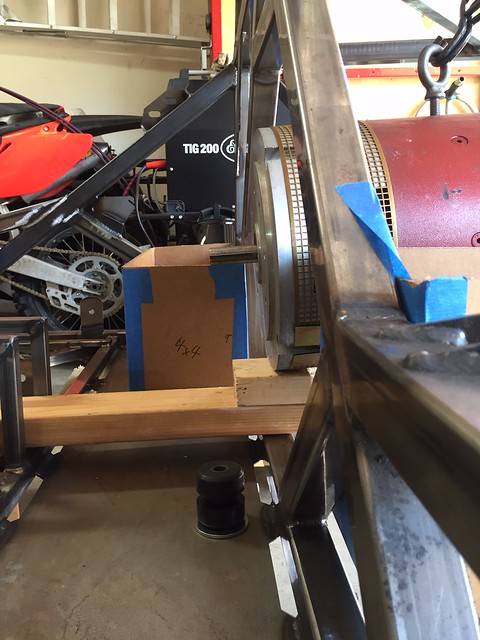

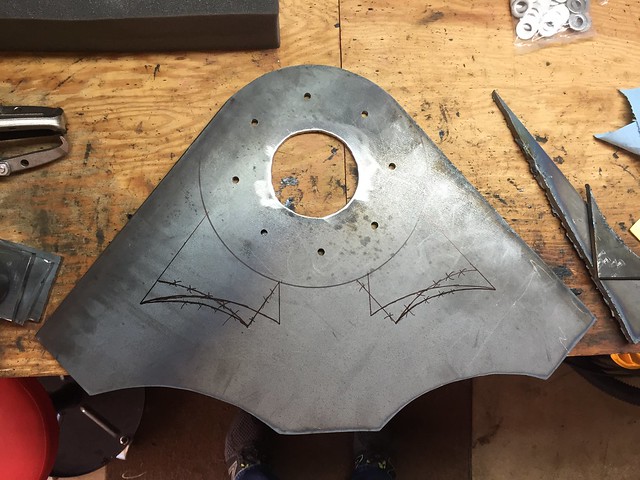

Talked to Michael over at EVWest and he suggested I countersink the adapter plate to gain some clearance. Going to attempt this on my drill press ... nice a slow ....

Talked to Michael over at EVWest and he suggested I countersink the adapter plate to gain some clearance. Going to attempt this on my drill press ... nice a slow ....