Popular topic at least on FFCars. Wondering if anyone else has seen this?

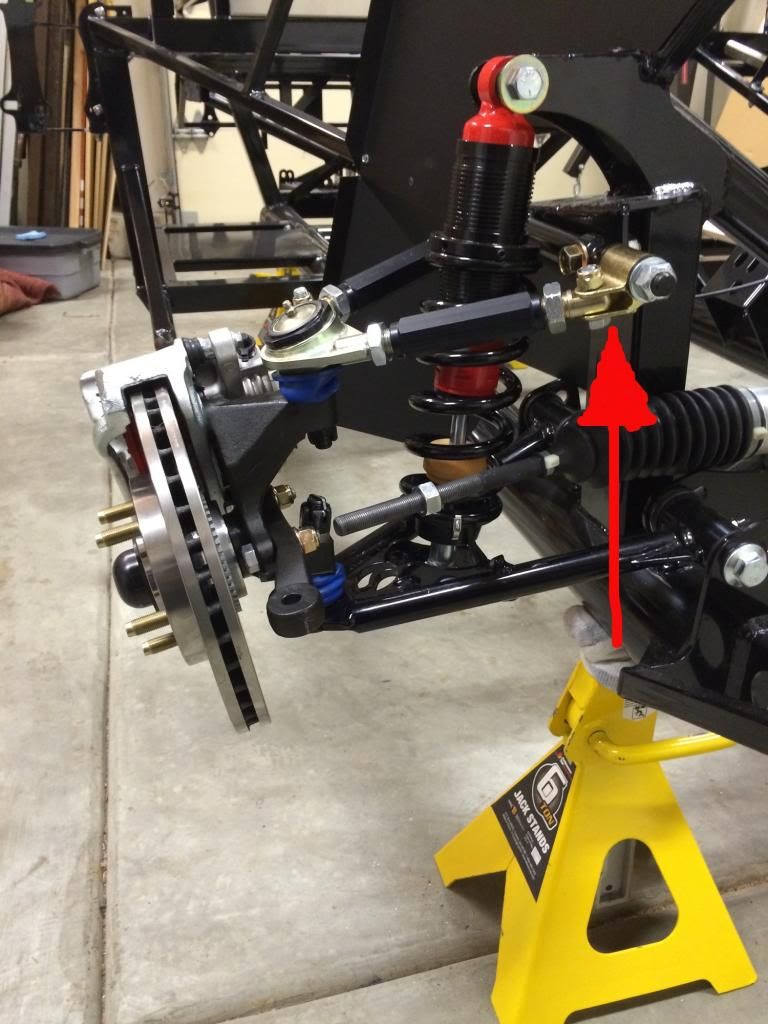

1500 miles in, my driver's side upper control arm snapped while driving (I was turning left, stopped and felt something snap... just before a SEMI missed me). I limped along about 40 yds down the road, pulled over and saw the driver's side front tire with a hell-of-a-lot of instant positive camber.

I towed her home.

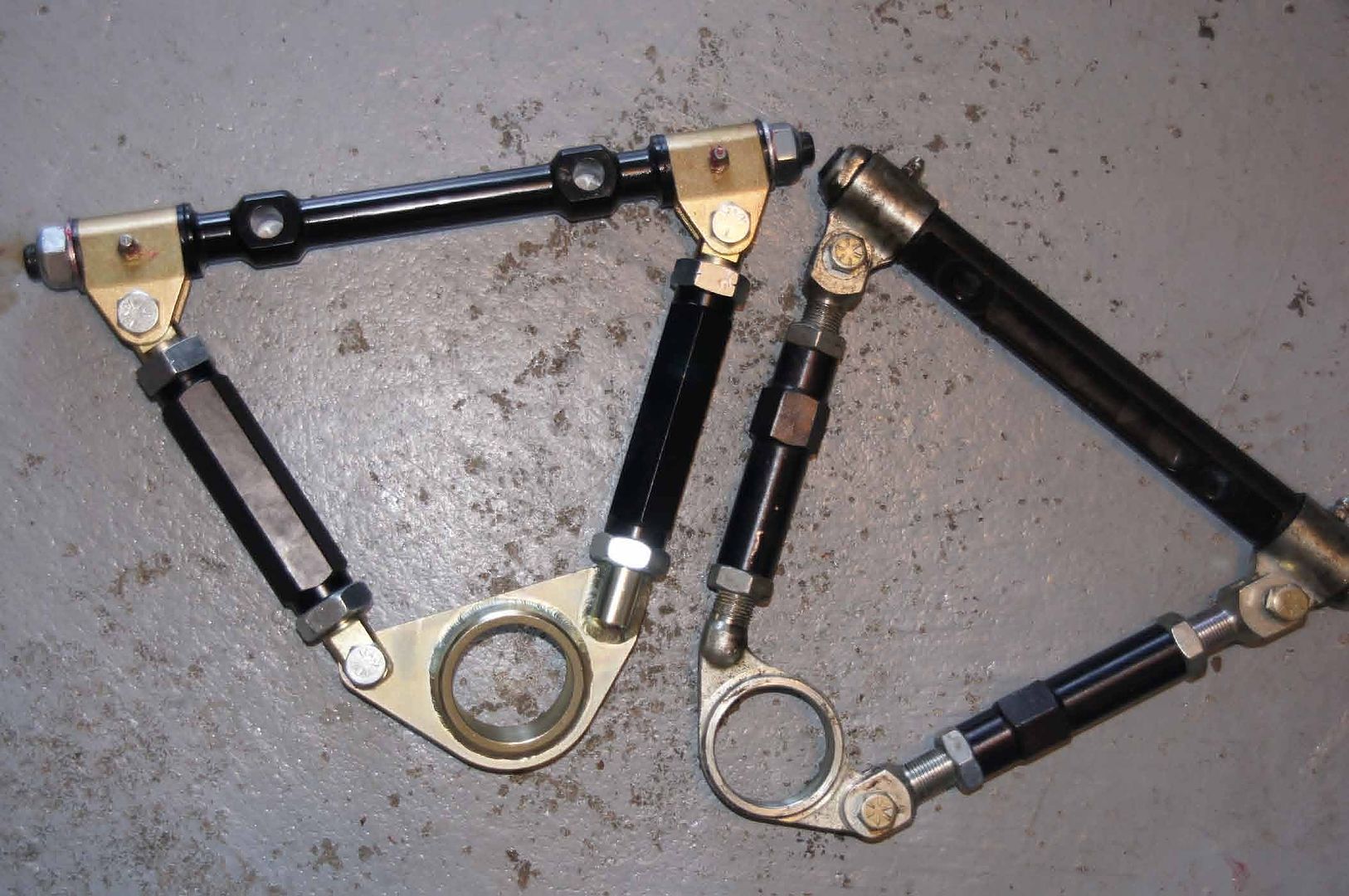

Jacked her up, took off the tire and saw this.

UCA Fail sm.jpg

Seems to be a commonly broken part according to other posts. I called FFR, ordered 2 new front UCA's. The parts girl at FFR was not aware of a failure rate (and no hint of replacing this). She was in a hurry to leave as it was 5pm Friday... so I just went ahead and paid the 2x$229 and had them shipped. I plan to replace both sides while I'm at it.

*NOTE* Incase it matters : I am using donor Mustang OEM lower control arms.

Kind of un-nerving. Any similar experiences? Did I do something incorrect? Some suggest a lack of lube. I am suspecting the UCA itself. Please share your thoughts.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote