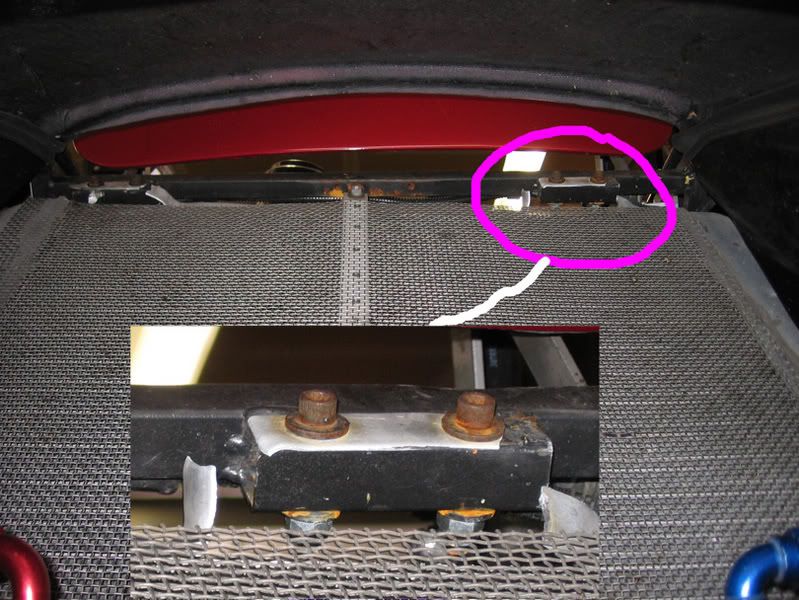

Has anyone else had a radiator go bad prematurely on their Roadster? I've driven mine just over a year and I recently developed a leak. The failure is up high on the front near the upper inlet where the top rail bolts to the 3/4" tube. Apparently the radiator has been experiencing some stress at this point, such that one of the tubes ruptured... My local radiator expert was amazed at how little support there is for the radiator, has anyone else had the same trouble and or have you supported your radiator better than stock? I bolted and mounted mine according to the manual...

20160208_103643_resized.jpg

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

)

)