Visit our community sponsor

Thanks:

0

Likes:

0

-

Wiring harness placement question.

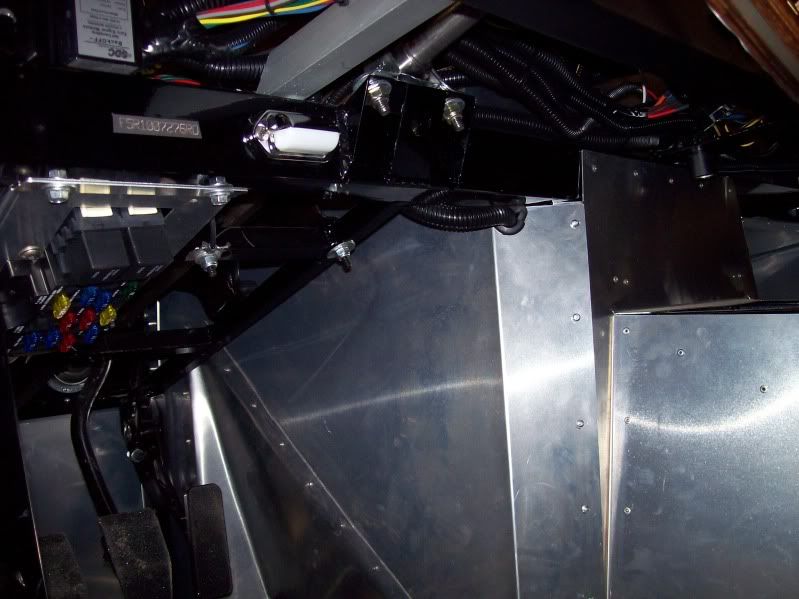

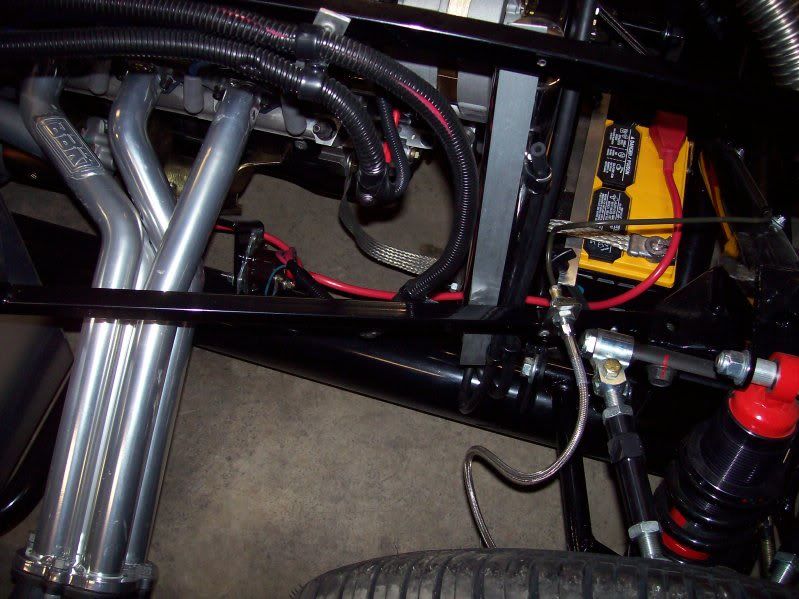

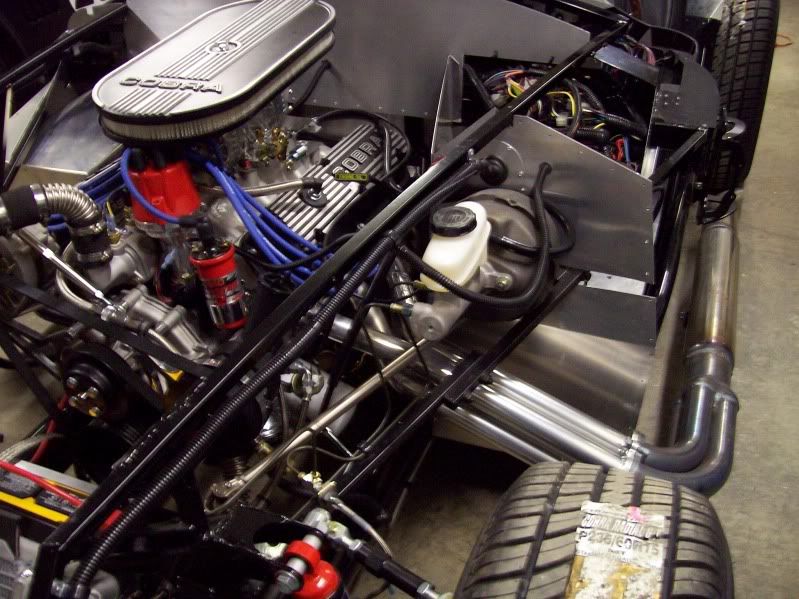

I got into laying out the wiring harness this afternoon. The directions are pretty vague but I'm fumbling my way through it. How do you guys keep everything neat and out of the way of the master cylinders and cutch and accelerator cables. Also the rear harness, alternator, starter, and sending unit wires seem to all need to run out of a mysterious hole in the engine side of the drivers foot box. I have no such hole! Should I drill a hole and put a large grommet there? Any pictures of pedal box neatness and wiring routing would be gratefully appreciated!

Thanks as always

-

Not a waxer

-

Jeff that's perfect. The patch panel you are referring to, I don't see it in the panel. I see we're you went through the firewall but don't see the panel. I like the idea of extending the alternator and solenoid to get them to the passenger side! I have the rear harness ran and looking good and I understand the front harness. It was that mystery hole that had me stymied. I will drill a hole and get a grommet for it.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Visit our community sponsor

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote