Visit our community sponsor

Thanks:

0

Likes:

0

-

Driveshaft mounted parking brake

Quick background: I'm building a MKIV base kit using Gordon's Wilwood brakes for 15" Halibrands and the new IRS setup. 15" wheels for street, 18" for track, but I'm still relegated to brakes that fit the smaller 15 inchers. This option unfortunately doesn't allow for many parking brake options since the often used spot caliper doesn't fit inside the rim according to Gordon. He offered a line lock-style hydraulic parking brake and I think is still working on some other option. I didn't like the hydraulic idea for a number of reasons that I won't get into here.

I decided to take a page from my Jeep/offroad history and go with a driveshaft mounted disk setup. This is often used for either parking brakes and/or regular brakes on Unimog and other portal-style axles used in offroading where mounting standard disks is simply not an option.

First was getting all of the right yokes for the T56Magnum and Super 8.8 rear diff, both with 1350 style u-joints(WAY overkill). I documented that challenge in a different post but in summary if you have a T56M and new IRS and want 1350 ujoints, the Spicer part numbers you want are:

3-2-119(Super 8.8 pinion flange yoke)

3-3-5961X(31 spline T56M slip yoke)

5-1350X(1350 series non-greasable ujoints)

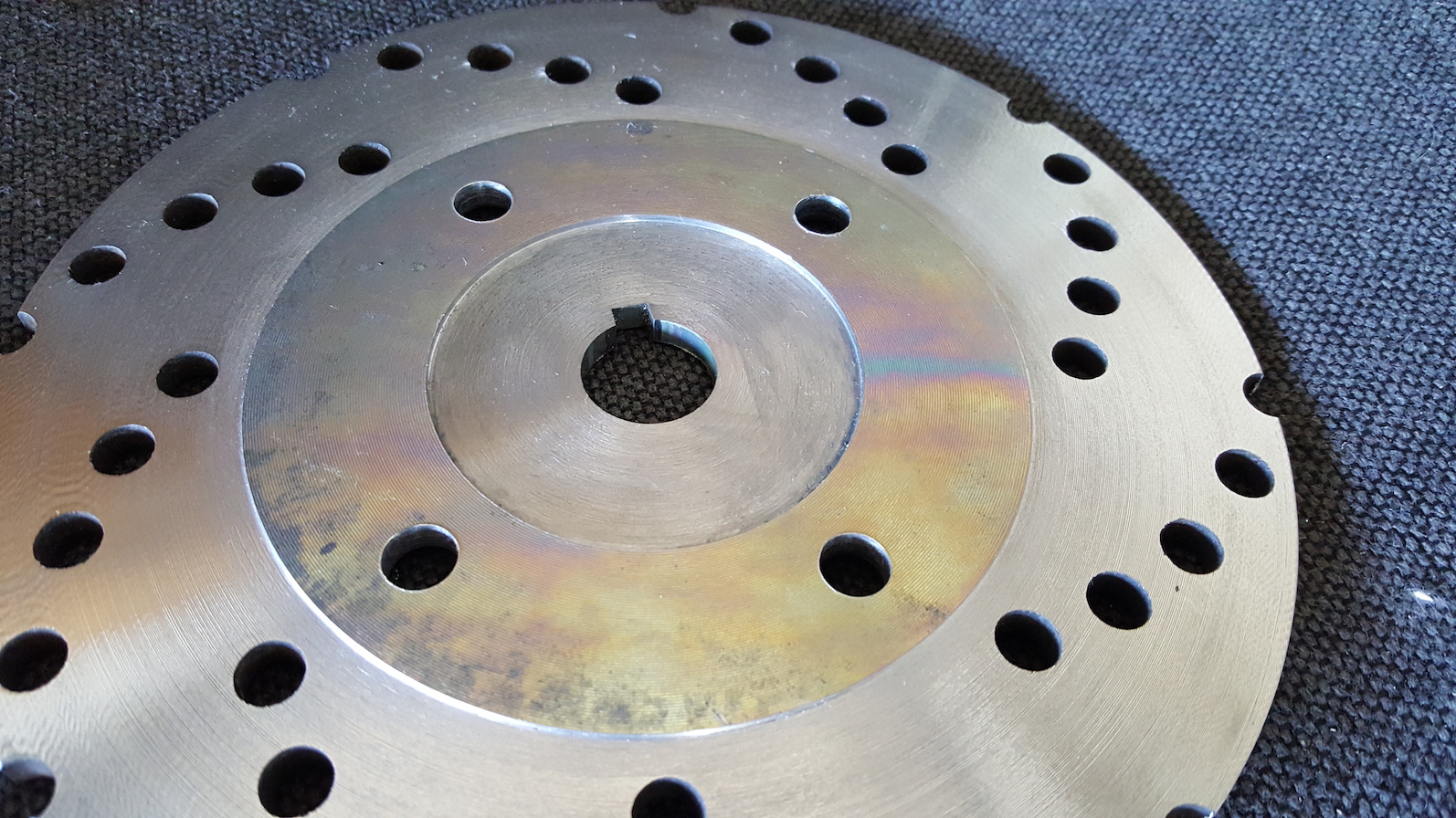

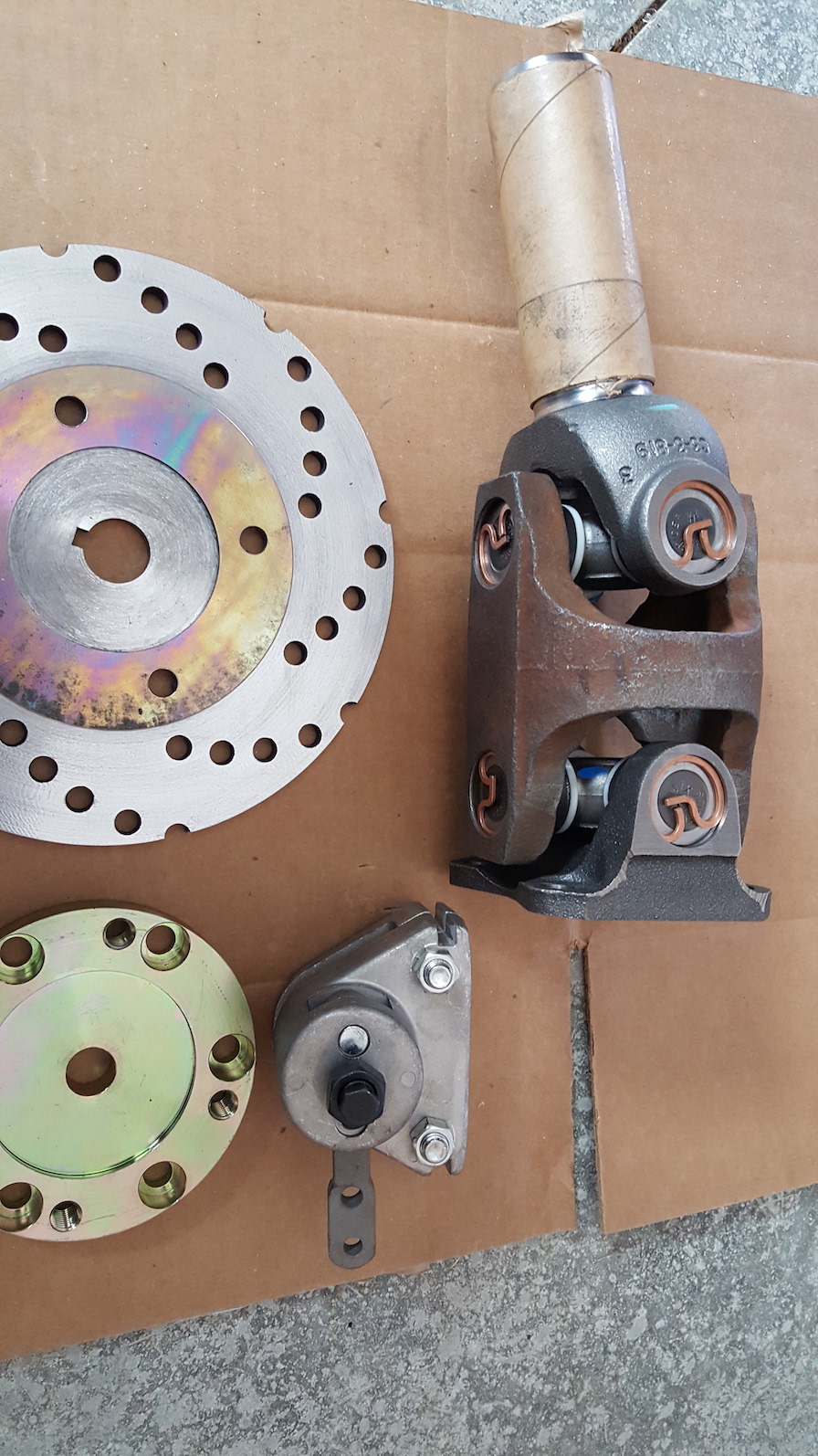

Next was finding a suitable disk. I'm heavy into the snowmobile world and between my brother and I came up with a late model 1/4" thick heat treated disk off a sled. It was drilled(unnecessary for my application), slightly too large of a diameter, and had large 1" mounting flanges on each side. I faced one side on a mill(the opposite side of what's in the pic below), then drilled the mounting holes for the pinion adapter on the same mill. Next I bolted the flange adapter and rotor together then chucked it in a lathe and turned down the rotor on the other side, cleaned up the braking surface, and brought the overall diameter in 1.5" so it fit between the tunnel tubes. In the pic you can see I milled the same flanges into the face of the rotor that the pinion adapter and yoke flange have. One side is raised on the horizontal plane, the other side is sunken. This centers the parts perfectly(.002" tolerances) and allows for only radial load and not vertical load. It turned out perfect.

I needed all of this to measure properly for a driveshaft. With the monstrous T56M, my engine placement, and the extra width of the 1/4" brake rotor, I needed a driveshaft 4" center of ujoint to center of ujoint. Went to a local driveshaft shop that specializes in heavy truck and equipment and he shrugged and said "sure, I can make it that small but can you use one 3.5" instead?" There is plenty of travel in the T56 slip yoke and sticking out another .5" wasn't going to matter so I said "sure". He handed me the center of a huge CV joint that was 3.5" center to center and said $35. It is WAY stronger than any short-tubed welded driveshaft, no need to properly phase it, and works perfectly. BOOM! There's about $200 in savings from a custom shaft.

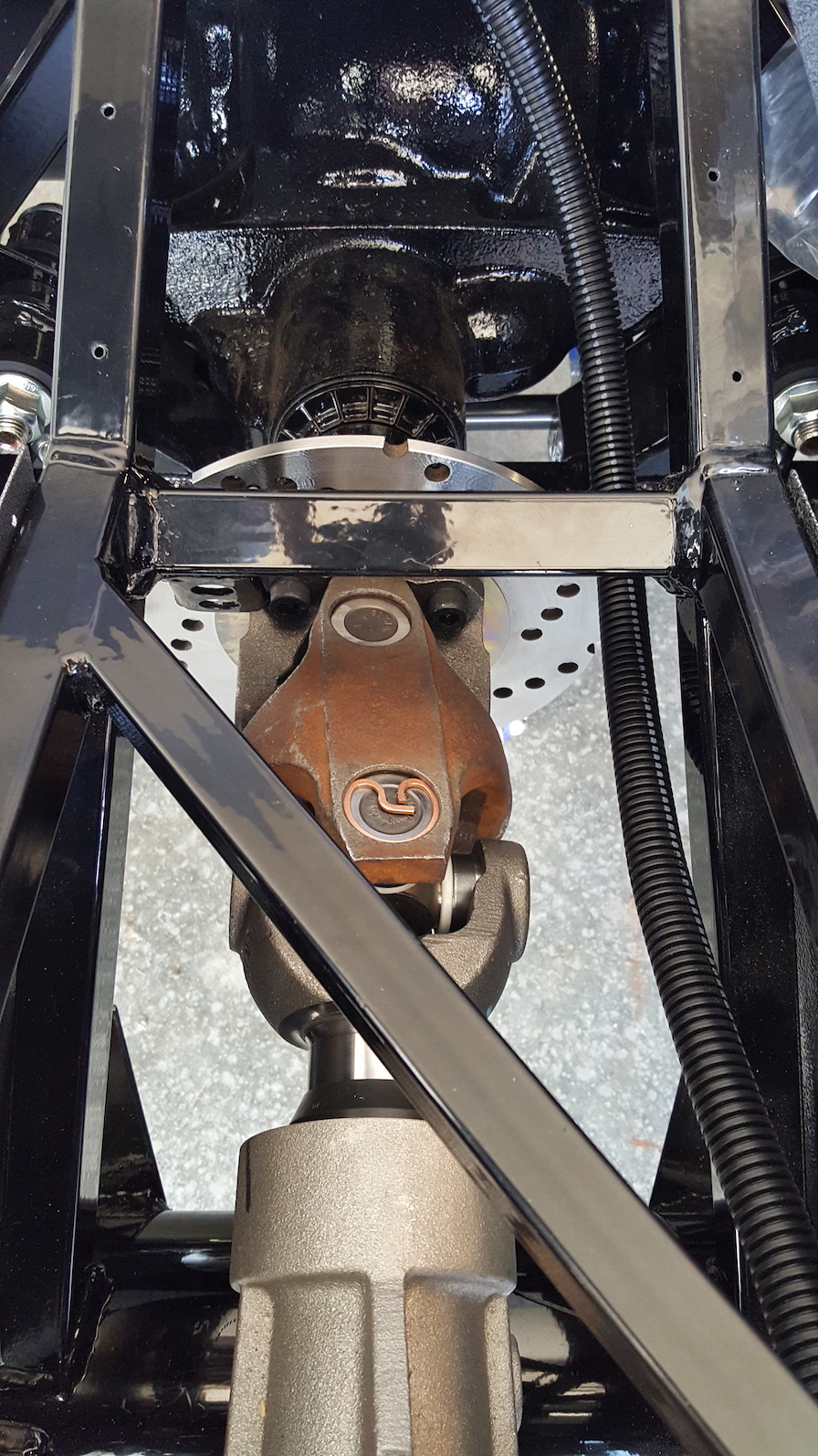

Here it is all assembled. I still need to set all of my final angles but the flange faces are all already within 1*. The diff is offset to the passenger side more than my engine/tranny(damn that T56 is big...), but using all the same principles as long as all angles are equal and opposite it doesn't need to be lined up. In fact, ujoints need at least .5* of offset/angle or you get brinelling which is when the roller bearings don't actually roll inside the ujoint caps.

Bonus points for anyone that can see what's wrong in this picture.

I still need to build the bracket that holds the mechanical caliper on the rotor(caliper in first pic). It was a $26 Amazon item from a go-cart shop but during intense inspection, it is LITERALLY the exact same aluminum casting and design that Wilwood sells for $95 except theirs is powder coated and has what I can only assume is a $69 Wilwood sticker on it.  Along with the caliper bracket, I plan to pic up a Pontiac Fiero parking brake lever and mount it on the floor to the left of the driver's seat, tucked away and somewhat hidden. The Fiero lever is unique in that once you pull it up to engage, you can push the handle back down(still engaged though) to get it out of the way.

Along with the caliper bracket, I plan to pic up a Pontiac Fiero parking brake lever and mount it on the floor to the left of the driver's seat, tucked away and somewhat hidden. The Fiero lever is unique in that once you pull it up to engage, you can push the handle back down(still engaged though) to get it out of the way.

In the end, I think the solution will work out very well. It's a mechanical setup instead of hydraulic which is what I wanted and plenty strong enough for a parking brake. Only time will tell just how good the brake and CV joint "driveshaft" truly work though. I'll need to get the car moving on it's own and rack up some miles before I claim any kind of real victory.

-TJ

-

Senior Member

Looks like your missing one of your U-joint Clips!

Cool Idea for an E-break set-up.

Last edited by Lowrod; 06-12-2017 at 11:30 AM.

-

Not a waxer

A question, not a critique---concerns about balance? At 70-80 MPH that rotor is spinning 3-4,000 RPM depending on rear end ratio. We're talking about a significant amount of inertia if the rotor and shaft balance isn't spot on.

Jeff

-

Senior Member

Holy crap. I just installed my driveshaft yesterday(Coyote/TKO/IRS) and I would have never believed there was room for a driveline brake there if you didn't post pictures. Can't wait to hear how well it works.

-

Seasoned Citizen

Clever idea and execution. Should work fine as a parking brake. I've worked on heavy trucks that utilize the same technology for a parking brake. Not sure what you're objection to a juice parking brake is but just for future reference, they are common factory items on some aircraft. Very compact, simple, and light weight. Im also running both 15" & 18" wheels on the back but keeping my 12.19" rotors by using the more compact Wilwood Dynalite Pro calipers. I'm not planning a parking brake for my car but if I determine I need one will use an aviation style mechanical hydraulic valve to set the brakes.

-

Pretty cool TJ; thanks for sharing. I have a pinion brake setup on my coupe (gen 2 with Thunderbird-style IRS). I used an off-the-shelf pinion rotor from Superformance, Hank L. machined a stepped adapter for me, and I sandwiched it between the pinion flange and driveshaft. It's grabbed by a hydraulic Wilwood spot caliper, which is actuated by a hydraulic (and locking) drift brake handle. The bracket for the spot caliper is grafted into/onto a Forte's driveshaft loop. I have no idea how it works as the car is still in (slow) progress. Also, I think you will like the e-brake handle to the left of the driver's seat. That's where mine is and it seems pretty natural. Well done!

-

Originally Posted by

Lowrod

Looks like your missing one of your U-joint Clips! Cool Idea for an E-break set-up.

WINNER! Yep, had to remove the snap rings to get accurate measurements for u-joint angles.

Originally Posted by

Jeff Kleiner

A question, not a critique---concerns about balance? At 70-80 MPH that rotor is spinning 3-4,000 RPM depending on rear end ratio. We're talking about a significant amount of inertia if the rotor and shaft balance isn't spot on.

Jeff

I definitely do have concerns about balance. This setup is honestly heavier than I thought it would be(and hoping...) and there is NO way it's truly in balance. Even using a CNC mill to do the facing and other mill work, I'm sure it's off at least some. Not only is it spinning fast, but it's a wheel of death that happens to be right where your torso is. One saving grace is that the 3/4" tunnel bracing creates a natural "guard" of sorts. I had to install everything from the bottom since you can't squeeze it in from the top or side no matter what angle you try to get it in there. The driveshaft place said absolutely no shop would be able to guaranteed proper balancing given it's size, their machines aren't made to work on anything that short. There is definitely a chance that one of a few things happen. 1) It vibrates SOOO bad at speed that it's flat out a bad idea and not going to work, period. 2) Slight to no vibration felt but takes it's toll on both u-joints AND pinion and tranny bearings(I sincerely hope it's not this). 3) It's short enough that any off-balance is handled well by the relative proximity of the tranny output and pinion bearings. I'm clearly hoping for number three....

Originally Posted by

NAZ

Clever idea and execution. Should work fine as a parking brake. I've worked on heavy trucks that utilize the same technology for a parking brake. Not sure what you're objection to a juice parking brake is but just for future reference, they are common factory items on some aircraft. Very compact, simple, and light weight. Im also running both 15" & 18" wheels on the back but keeping my 12.19" rotors by using the more compact Wilwood Dynalite Pro calipers. I'm not planning a parking brake for my car but if I determine I need one will use an aviation style mechanical hydraulic valve to set the brakes.

I had concern for a few things with the hydraulic setup. For anyone not familiar, a common mechanism is where you install a valve inline of the rear brakes. You step on the brakes hard, pull the valve handle, then let off the brakes. The front pressure is relieved, the rear pressure between the caliper and valve stays locked. The rear pressure between the valve and the master is slightly relieved with residual vacuum in the line. My concerns were mainly: 1) A leak-down scenario where the pressure doesn't stay high enough over let's say an 8-12 hour period(car parked on a hill over night). 2) Added stress of extended high pressure on the the caliper bores/seals. 3) It's not a separate mechanical system from the regular brakes(one fails they both fail). 4) Although I didn't find WI registration info specific to #3, I was worried it "might" not pass inspection.

If Jeff's and my shared concern comes true about balancing issues, I'm absolutely 100% going back to this option. Are the systems in a plane used to hold an object for extended periods of time? Do they use relatively standard parts or high-dollar specialty parts?

Thanks!

-TJ

-

Moderator

I did something similar once, using AP Racing parts. This is the best pic I have of it.. worked well. Cable actuated though.. some rulebook necessitated a non-hydraulic backup.

ebrake.jpeg

James

FFR33 #997 (Gen1 chassis, Gen2 body), license plate DRIVE IT says it all!

build thread

My build: 350SBC, TKO600, hardtop, no fenders/hood, 32 grill, 3 link, sway bars, 355/30r19

Previous cars: GTD40, Cobra, tubeframe 55 Chevy, 66 Nova, 56 F100

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Visit our community sponsor

Along with the caliper bracket, I plan to pic up a Pontiac Fiero parking brake lever and mount it on the floor to the left of the driver's seat, tucked away and somewhat hidden. The Fiero lever is unique in that once you pull it up to engage, you can push the handle back down(still engaged though) to get it out of the way.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote