Good job on the welding. If you would have done this a month ago, I could have said you created the first FFR pickup, but I think they beat you to it.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

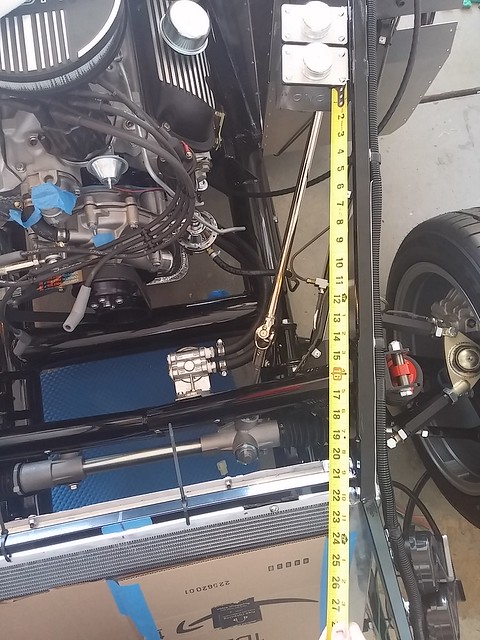

Unload the springs with a floor jack when adjusting. Don't try to adjust them under load. Some recommend some anti-sieze on the threads, and green Loctite (the wicking kind) for the sleeve to the body to keep it from turning. I've never done either and not had a problem. But keep an eye on it and do what works for you.

Unload the springs with a floor jack when adjusting. Don't try to adjust them under load. Some recommend some anti-sieze on the threads, and green Loctite (the wicking kind) for the sleeve to the body to keep it from turning. I've never done either and not had a problem. But keep an eye on it and do what works for you.