There has been talk in several threads about what it would take to make your own body to put on an FFR frame.

See posts #13 and onward:

http://thefactoryfiveforum.com/showt...st-hear-me-out...

Artists and custom car makers from the 1960's and 1970's like George Barris, Dick Dean, Ed Roth and many others did "one-offs" all the time. This was in an era before 3D computer drawing programs and CNC milling. So how did they do it?

There has got to be more efficient ways today, to make limited production or one-off custom car bodies.

I'm open to suggestions.

The reason I started this thread is because I clicked on an article in Yahoo news which captured my imagination.

Man builds his own million dollar Bugatti supercar by hand

http://news.yahoo.com/blogs/technolo...211223675.html

Mike Duff.....the 25 year old

http://digitsup.blogspot.com/2011/07/mike-duff.html

Cougatti

http://straightfromthea.com/2011/07/...cougar-photos/

So far I have found little technical information about how Mike Duff pulled off what he did. I don't even know if the engine is still up front. There is mention of foam, fiberglass and a tube frame, but not much more to go off of.

Mike Duff is not the first guy to do something like this, just the latest in a long line of "can do" and "why not" people who have done it.

The two part foam crazy Russian method still looks most doable. However based on my limited hovercraft building/modifying experiences, it's not as easy as it looks, the foam absorbs moisture causing future weight gains, and it's just plain toxic and messy to work with.

The Russian

http://englishrussia.com/2008/05/29/...s-and-pu-foam/

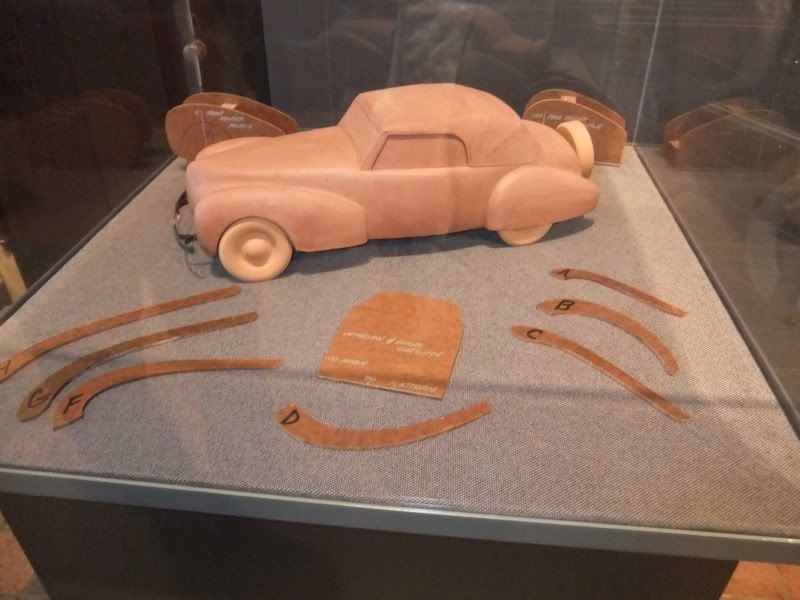

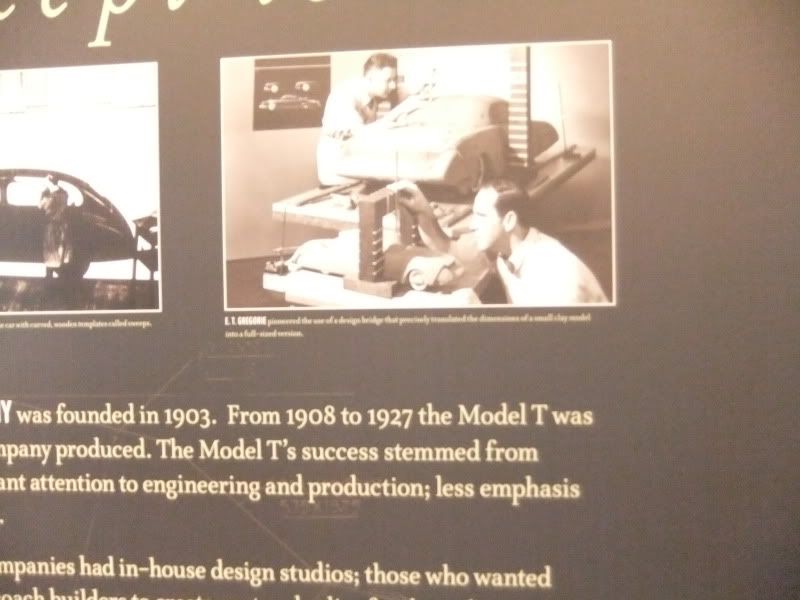

Based on clay car building at home, getting things symmetrical is a real challenge, at least as much as a challenge as it was 100 years ago when all car were "hand built". Templates, ships curves and so forth must be used to end up with predictable results. Where do you get them, make them and how are they used?

Ship Curves, as photoed in the garage of the Edsel & Eleanor Ford estate at Eyes on Design - 2011.

http://s184.photobucket.com/albums/x...pZZ18QQtppZZ20

http://s184.photobucket.com/albums/x...pZZ15QQtppZZ20

Model first?

http://s184.photobucket.com/albums/x...pZZ15QQtppZZ20

[IMG][/IMG]

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote