I spent almost all day, trying once again to figure out how and where to mount the fuel system components...

Using the Aluminum Fuel tanks, and The fuel pump and filters are taking up much more time than I ever thought they would.

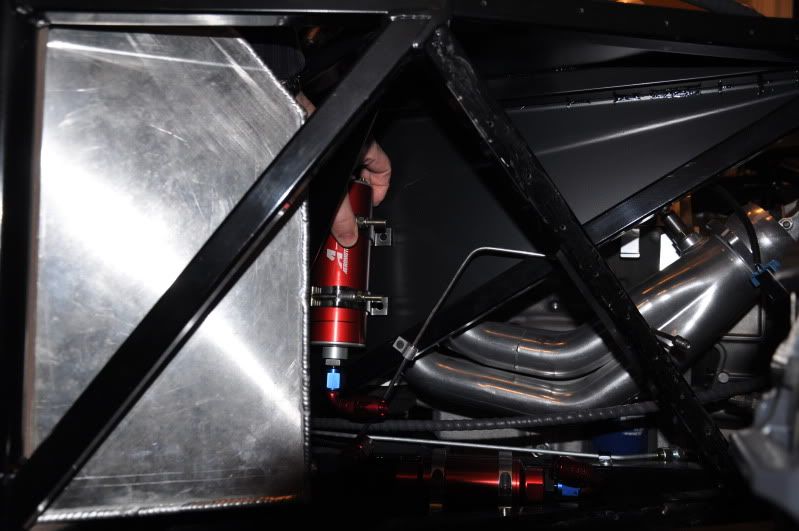

There just doesn't seem to be enough room to mount the pre-filter (100 micron) and the fuel pump in the area behind the driver's side tank.

I'm convinced that they both need to be mounted horizontally, on or as near the floor as possible.

The problem is that there is really only room for either the pump or the filter to be mounted on the floor. That means that the other has to be mounted somewhere close by; also horizontally.

The most logical place would be the outside panel (next to the tire). The filter can be mounted there, but the AN fittings between the fuel tank and the filter "intake" port are very close together, making it next to impossible to run a braided line with fittings without creating a loop and then attaching to the filter.

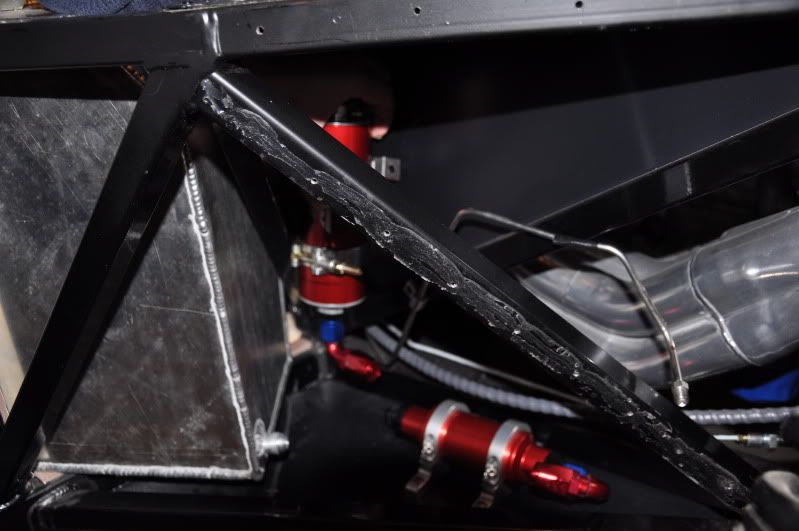

The problem with mounting the filter on the outer panel, is that it makes changing the filter cartridge pretty hard as well. The panel would need to be removed. But before the panel can be removed, the brake line and the fuel line to the filter would need to be disconnected.

Then I had a thought that I could make the floor panel removable for access to the pump and filter. But the pump is mounted to the floor, which means the same type of issues would exist...

The next idea, is to cut an opening into the outer panel to gain access to the filter and pump. Then make a cover panel that can taken off without needing to disconnect everything else.

It shouldn't be this tough. There must be something that I'm missing.

I did at least get the heat shield / sleeve onto the shifter cables...

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote