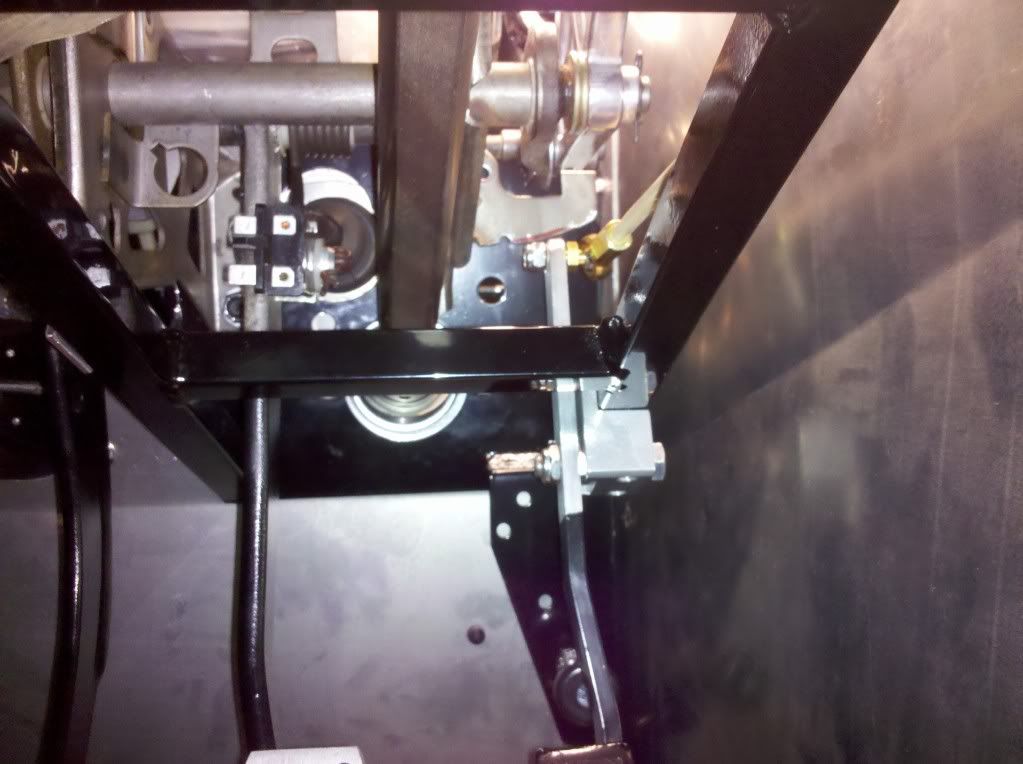

Here's a picture of my mechanical throttle linkage mocked-up with wooden dowels. Since I have quite a range of adjustment at the gas pedal with this set-up, I'm looking for recommendations as to a good length of travel for the gas pedal. Do any of you have preferences? Given the high horsepower and low weight of these cars, I'm thinking more travel is better, but I don't want it to be too much. I'll tweak it once it's in go-kart stage, but I'm looking for a suggested starting point.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote