-

302 SBF and T56 Magnum do not fit in a Gen 3 coupe.

For my coupe build I decided on a SBF 363 with a T56 Magnum and last week I got the T56 mated to the engine so, a buddy and I attempted the engine install. We got the motor in, and I took a look at the trans mount an sure enough, it didn’t fit. The mounting location on the trans is about an inch and a half farther back than the gen 3 coupe allows for. I guess I should start off with what my engine and trans combo is, so folks know how it relates to them and have a better idea of what I am talking about.

Engine: Ford 302 stroked to 363. Dart SHP block.

Engine mounts: Levy racing supplied solid engine lowering mounts.

Bell Housing: Quicktime RM-8030

Transmission: Tremec T56 magnum TUET-11010

I didn’t think this was a rare engine and trans combo for the coupe, but it turns out that it is. I called FFR and they said that it was a very rare combo and that I would need to make a new trans mount. I also called Gordon and he was super helpful but, he also concluded that I would need to make a new trans mount. Another measurement I looked at was driveshaft length. Apparently, with a Coyote and T56 the driveshaft length is 9.75inches. My transmission tailshaft to pinion flange measures just over 8.5inches. So this seems inline with the fact that the 302 places the engine about an inch back in the coupe frame. The T56 also seems too tall and wide for the trans tunnel with the 302. I am working on a path forward with making a new trans mount. See picture below for more detail.

Here is a pic of the Levy racing provided engine mounts.

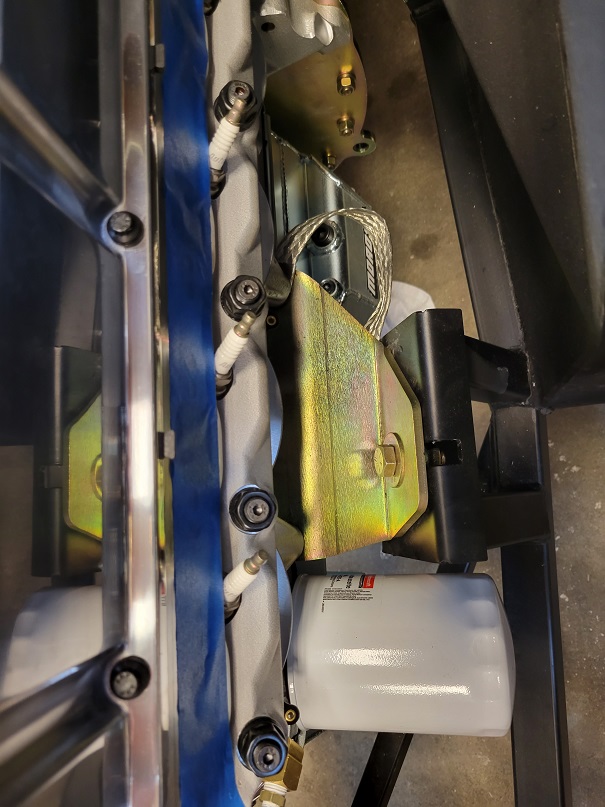

The next two pictures are of the transmission mount plate in the factory location(with it reversed). You can see that the mount is roughly and inch and a half off.

This picture is a wide angle view of the factory trans mount location. You can see that the T56 hangs below the trans mount and spacers would be needed even if the holes lined up. The next picture shows that the top of the trans(Without the shifter installed) is right up on the trans tunnel cross bar. That bar needs to be notched or the trans lowered to make it fit.

The next few pictures show a tentative mounting location of the transmission mount. I basically turned the mount around and laid it on top of the cross member just aft of the trans mount. This seems to fit fairly well but, as I mentioned above, I would need to notch the crossbar in the trans tunnel to get the shifter to fit. With how it sits with the tentative mounting location, the transmission and pinion flange are 0.8 degrees off from parallel and the drive shaft would have an angle of 5 degrees. I could move the transmission lower to decrease the driveshaft angle but this would increase how out of parallel the trans and pinion flange are.

The main reason for this post was so that others that are planning their build know what they are getting into if they want to do a T56/302 build. Also, I wanted to see if there is anyone out there that has done this combo before and done it successfully. Is there anything that I am missing or have not thought of that would lead to the trans mount being so far off? Thanks for reading and please send your thoughts and suggestions my way.

V/R

Shakey

-

Other people have done it, a local friend has a 351/T56 in his, but it did take a little effort and from what I remember simple mods.

Exercising creativity is part of the build process.

Jim

2016 Mk4 Challenge Car, IRS, 3.31 Torsen, RDI Aluminum 427w, AFR 225s, Vic Jr. ProSystems 780 HP, TKO-600 w/Liberty mods. Forward cage. Levy 6/4 piston Wilwoods. Not completed yet, will be a streetable track car.

2004 Superformance MkIII #1855, 2007 Superformance MkIII #2584 purchased in 2012 both sold.

-

Senior Member

Surprised FF would tell you that, e.g. not a common combo. Maybe more than likely they're saying a T56 in general isn't that common. But there's no reason you can't make your combo work. My Coupe has the Coyote + T56 + kit provided Energy Suspension mounts. No sure what your motive is for the different mounts. But regardless, I can agree that the Coyote puts the transmission about 1" closer to the front. I didn't find the tunnel too small, even with the more forward location. The Gen 3 coupe has quite a bit more tunnel space than a Roadster and guys put the T56 in those.

Take them one at a time. For the shifter, if you flip the shifter around on the rear mount, does that give you enough clearance to the tunnel cross bar? That's how I have mine, and it widely clears the cross bar. Even with the 1" difference, you might have room. Some guys cut the cross bar. Have only seen that in the Roaster where it's thin material and doesn't appear to be structural. Don't think that's the case on the Coupe plus I'm in the no cut frame camp. But cutting and rewelding something is an option. Another would be a midshift kit. But that's a more significant change and IMO would put the shifter too far forward. Maybe into the front trans cover and tight to the dash.

For the trans mount, I was able to get mine to fit by flipping over and reversing. You say yours is 1-1/2 inches off. That sounds like a lot and maybe would be less with a different orientation. But if you're fabricating a new one, that should solve it.

For the driveshaft, agree you will need a shorter one than mine with a Coyote. I'm assuming you specified your engine/trans combination when your kit was ordered, but FF supplied a driveshaft that doesn't fit? I'd be talking to them about that.

Hang in there. The T56 is nice and worth the effort in my experience.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Senior Member

You might try to flip the motor mounts left to right and see if that moves your engine enough to make a difference.

You can cut and reweld the cross brace to clear the shifter.

HTH

John

-

Senior Member

Kudos to pursuing this, but this isn't a case of the SBF + T56 Magnum "not fitting". Now get 'r done and make it work.

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Thanks for all the comments and insight! I am definitely doing a lot more fabricating and work with a cut-off wheel that I thought I would. Not a big deal as I enjoy that stuff.

My reason for going with the engine lowering mounts was so that I could run a taller intake manifold. I am using the super victor single plane intake and will still have to run a drop base air cleaner. My engine builder said that the super victor is good for 30+ HP over the victor junior so, I went with it.

After sitting in the car for a bit today, I think the best option will be to cut the cross bar out like others have done. This will allow me to put the shifter in the best location and keep the trans where it is right now giving me the best drivetrain angles. I then might see if I can get access/buy/learn to weld and put a support brace back in. The midshift kit isn't an option as it is too far forward unfortunately.

I should have mentioned that I got a base kit so I did not get a driveshaft with my kit. I was planning to have one custom made anyways.

Gordon also mentioned swapping the motor mounts side to side but as he said, and I agree with him, that it would have consequences and could affect handling or other characteristics of the car negatively.

I guess I am still surprised about how little talk there is about the 302/T56/IRS combo on the forums. I also looked at the FFR website again and they don't list a driveshaft option for a 302/T56 with an IRS. Maybe it is a rare combo.

V/R

Shakey

-

I haven't started my install yet, but I have a 347 with T56M. I spoke with FFR about this combo before placing my order and they didn't mention anything about it being rare or unusual. They told me what trans and driveshaft to select when I placed my order and I went with it. I'll be following this thread, and I'll post my experience when I get to that point.

I'm curious about this one statement though: "Gordon also mentioned swapping the motor mounts side to side but as he said, and I agree with him, that it would have consequences and could affect handling or other characteristics of the car negatively." Is the concern about moving the engine forward a little or something else?

John

-

FFR supplies a trans mount extender with the Coyote in the cobra. It would probably work for your situation without having to modify the existing mount. If you PM me I probably have several laying around. I can send one out to you.

Mike

-

Wow, glad I read this as I am just about to place an engine/trans order and was debating along the same lines. Very similar build and reasoning in fact. 363 (more induction choices vs 351 block) and was thinking about T56 vs TKX, though leaning TKX.

-

Senior Member

Swapping the mounts would move the engine forward about 3". The balance on the car changes so spring rates and setup changes, headers would not line up properly, other frame members may become issue with clearance for the oil pan and other possibilities. etc... For every action there is a reaction, take all of them into count.

99/2000 NASA PSO Champion-2005 west coast FFR challenge series Champions

Sponsor Tony B's 2007 ST2 National Championship

2009 NASA TTC runner up-2010 NASA TTB runner up

-

Originally Posted by

Gordon Levy

Swapping the mounts would move the engine forward about 3". The balance on the car changes so spring rates and setup changes, headers would not line up properly, other frame members may become issue with clearance for the oil pan and other possibilities. etc... For every action there is a reaction, take all of them into count.

Thanks Gordon.

-

I have not made any big modifications to the frame yet. I guess I am still chewing on it. Kind of glad I did wait as Mike Everson might have a solution for the trans mount. Big thanks to him! I will follow up here as to what results I have but, I am hoping it fits well.

Now on to the driveshaft. I placed an order for a custom driveshaft and a few days later the vendor got back to and said the driveshaft is too short and they can't make it. It measures 8" from the end of the T56 output shaft to the face of the flange. So, I called FFR and they said the shortest driveshaft they offer is 8.375" for the roadster with 302,TKO,IRS and they are not in stock. The said that this driveshaft is probably too long as well. Again, they mentioned how uncommon this combo is and referred me to Mitchell Drivetrain service (http://www.mitchelldrivetrainservice.com/contact.html) to try an source a shorter driveshaft. I guess Mitchell has a different way they make the shafts and they can do them shorter than other manufacturers. They are sending me out a slip yoke tomorrow so that I can do the measurement and we will see if they can build one.

More to come.....

V/R

Shakey

-

Senior Member

Just drill a new hole in the engine mounts 1 in aft, to shift the motor forward 1 in. Making a new transmission plate shouldn’t be too hard. Draw up a template and send it to sendcutsend if you have to. Then the driveshaft shop can make your driveshaft. Many many options to move forward. Those being the easiest. Next is maybe moving the motor mounts on the frame.

-

Too short, well maybe but probably not. A friend has a Viper V-10 / T-56 combo in a roadster. Used a double u-joint piece from the truck industry, it's about 4" long.

I'd call around, you'll find someone that will make a short driveshaft.

Jim

2016 Mk4 Challenge Car, IRS, 3.31 Torsen, RDI Aluminum 427w, AFR 225s, Vic Jr. ProSystems 780 HP, TKO-600 w/Liberty mods. Forward cage. Levy 6/4 piston Wilwoods. Not completed yet, will be a streetable track car.

2004 Superformance MkIII #1855, 2007 Superformance MkIII #2584 purchased in 2012 both sold.

-

Senior Member

I have someone that can make your driveshaft

99/2000 NASA PSO Champion-2005 west coast FFR challenge series Champions

Sponsor Tony B's 2007 ST2 National Championship

2009 NASA TTC runner up-2010 NASA TTB runner up

-

Steve >> aka: GoDadGo

1. A Little Cutting, A Little Welding, A Little Mod Here & A Little Mod There!

2. Trust Me That Soon All Will Be Right With The World!

3. Here Are Two Motivational Videos:

https://youtu.be/PCngiKoopkA

https://youtu.be/9WEe6-wdNtA

You'll Definitely Overcome These Little Obstacles!

Last edited by GoDadGo; 06-22-2023 at 07:33 PM.

-

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

I am a rookie builder and have the 302/T56 combo. I was texting with Hank and he had warned me about this issue. The cutting of the tube doesn’t bother me. The bracket looks harder but do-able.

I learned to weld last year, with a Harbor Freight flux core welder. Learned to weld as something to do while waiting for my kit to arrive.

I’m actually about to attempt welding in some 1 inch tube to support the fire suppression tank that I bought.

Another part of the build that looked relatively simple but has turned out to be quite involved.

There are certainly a lot of learning curves for me on this build and I feel way out of my depth. But it will be worth it in the end!!

-

jgray,

I agree that it is 100% do-able and will definitely be worth it in the end. I don't know why I waited to buy a welder for so long. Welding with flux core turned out to be way easier than I thought. Super happy that I got it and now I have another great tool and skill for the garage. I hope all goes well with your powertrain install.

Shakey

-

Driveshaft Installed

Late post here but, I thought that I would share some pics of the driveshaft installed. I got it put in about 3 weeks ago and it was pretty straight forward. It is a short little guy. Mitchell Drivetrain was good to work with and got the driveshaft made in a timely manner. Drivetrain is now fully installed.

-

Congrats on getting it all done. That drive shaft is short!

If you have any more photos of your transmission mount , after you drilled it and when you said it was real flimsy, I would love to see them. This part of my build is probably at least a couple of months away so I figured I would ask you now while the whole process is fresh in your mind.

Also, how did you go about figuring out how to modify the mount - presumably you had the engine and trans on the hoist and part way installed?

All of this is new to me, so the description of the basic steps would help me plenty. I am going to have help but they will only be available intermittently, so I want to be as prepared as I can to make progress when I have people over helping.

-

-

Hi Shakey,

Thanks - just the type of info that I was looking for!

Your fire suppression photos are very helpful! My Fire suppression system has a remote automatic activation head that has one line flowing to it (from the tank - down the trans tunnel) and two flowing out - one for the two gas emitters in cabin (it has a tee in it) and one for the two emitters in the engine bay. The activation head also has the connections for two pull cables, one for the driver, one external for race course worker. The activation head has to be the cabin because it goes off automatically at 200 degrees. And the head needs to be where the driver can pull out the two safety pins for the pull cables prior to a race! So this adds quite the puzzle to an already complex dash and behind dash layout.

One of my concerns has been putting the fire suppression pull cable in a location that will be strong enough to stand up to be yanked on hard in the event of actually having to use it! I am welding in a vertical support with a gusset for the pull cable to go through that will be just behind the 0.040 dash. Probably overkill but that is my approach. I also welded in an extra 1x1 in the area above the diff/axle so that all four bolts from the fire suppression tank harness. Putting my harbor freight flux core welder to work with my novice welding skills. The fire suppression kit comes with 5/16 aluminum tubing which I will run down the driver side of the trans tunnel as you described. I've been toying with the idea of using stainless. I used stainless 3/8 for my fuel lines and 3/16 for my brake lines. Learned to double flare stainless which was not as bad as I expecting. It is harder to bend but so far so good.

I've run my fuel lines down the passenger side trying to keep them tight to the side because of the T56 taking up a lot of space. Because I am running a electronic park brake (EPB) I actually cutoff the flat pieces that are in the tunnel that guide the parking brake lines and ran the fuel lines, one below the other where that bracket was. Hopefully that will work. I will run the rear harness down the driver side as you describe. I also have a harness for the EPB which will will run down that side too. Quite a lot running through the tunnel.

When you were working on the transmission mount I assume you had not run your rear harness? I've been working on all of my harnesses and dash ahead of installing my engine because my buddy who is helping with the engine has too busy and has suffered a back injury. So I am getting as much of the electrical and AC and other stuff done. I will remove it and reinstall if I have to.

Thanks for the guidance - I really appreciate it. I will be watching all the videos you just posted of you go-karting!

-

That sounds like an awesome fire system. I also ran all the lines and harnesses though tunnel before putting the engine in. So, when I welded the trans tunnel all the wiring and stuff was in there. I used an lot of shielding/welding blankets and stuff to protect everything. It seemed to work. Good luck!

V/R

Shakey

-

Shakey what oil pan are you using? I have a blueprint 347 with a 7.5" deep pan. to get my trans and diff axes parallel I need to either raise the transmission 1.1" or lower the engine 1.1". Problem is, raising the trans causes a severe driveshaft angle, and lowering the engine puts the pan .75" below the frame. What's your pan/chassis situation on your build? thx

John

-

JMo,

I am running the Moroso Drag/RR pan 20533 7.5in deep. I am also running Levy engine lowering mounts. This leaves the oil pan about a half inch below the frame of the car. With the IRS and T-56 setup that I have I didn't do any adjusting of the drive shaft angle. There just isn't any room in the trans tunnel to move the T-56 around. I will say that my Diff and trans output shaft are not parallel but there is certainly not a severe angle causing any issues. I have driven the car up to 60mph so far and no vibration issues or anything. With how short the drive shaft is and the fact that its an IRS I fell like it is probably understressed. Hope this helps.

V/R

Shakey

-

Member

Great info here Shakey! I'm following this with great interest.

I am eyeballing a parts farm running pallet coyote that has the T56 (see below) and is considerably less expensive than a complete Forte Package - new coyote and a TKO-600 one stop shop which is my current go to option but its about $10K more so....I think this is worth the consideration up front, and as far as the effort I'm not afraid of cutting, welding, and a new DS.

PS this would be for a Roadster.

The questions I have are:

1. If I had a complete running pallet setup is there anything else I would need like a different clutch/ throw out bearing / reservoir ect setup? Anything else unique you had to do parts wise using the T56?

2. What mount did you buy / Where did you get it from?

2. I f you dont mind... what was the cost for the custom DS?

Thanks in advance!

https://thepartsfarm.com/collections...trans-kit-5-0l

Last edited by M22_COBRA; 01-03-2024 at 09:48 AM.

-

Not a waxer

Originally Posted by

M22_COBRA

Great info here Shakey! I'm following this with great interest.

I am eyeballing a parts farm running pallet coyote that has the T56 (see below) and is considerably less expensive than a complete Forte Package - new coyote and a TKO-600 one stop shop which is my current go to option but its about $10K more so....I think this is worth the consideration up front, and as far as the effort I'm not afraid of cutting, welding, and a new DS.

The questions I have are:

1. If I had a complete running pallet setup is there anything else I would need like a different clutch/ throw out bearing / reservoir ect setup? Anything else unique you had to do parts wise using the T56?

2. What mount did you buy / Where did you get it from?

2. I f you dont mind... what was the cost for the custom DS?

Thanks in advance!

https://thepartsfarm.com/collections...trans-kit-5-0l

M22,

That is NOT a T56, it's a Getrag MT82. Although they have been used in Roadsters and Coupes they come with some challenges.

---The shifter is remote and way too far rearward for our purposes; Formacars makes a kit to relocate it the tune of $900.

---The MT82 uses a companion flange with Guibo joint, not a slip yoke. To use it in an FFR the flange needs to be changed and a custom driveshaft must be built to incorporate a slip joint.

---The provided rear trans mount is not compatible and will have to be fabricated.

None of these are insurmountable but will add significantly to the end cost which greatly narrows the ultimate price difference between using an MT82 versus the more common and popular TKX or T56. Beyond these issues the gear ratios in the MT82 are tuned more for getting a nearly 2 ton Mustang rolling and feature a very short first gear and big jump between 1st and 2nd which (at least in my opinion) are less than ideal for our cars.

Just food for thought.

Jeff

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

Thanks for pointing out the landmine to the newbie! lol Ok that changes things.

-

I just did a Godzilla and T56 magnum on a chassis set up for a Coyote, noting was close, I made new motor mounts with a swap kit from ICT Billet, used the trans mount, had to modify the tunnel brace too.

https://youtu.be/ZS8E9P5MPyY?si=huoy8LnvydzdSHOQ

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Hey Hank,

I wish I had a good answer for you but I don't. I measured my driveshaft length right at 8 inches from the tail shaft to face of pinion flange. FFR said their shortest one was the one you have which is just a bit longer. I went ahead and ordered a custom one after that talk with FFR. I certainly don't know enough about the T56 or drive lines in general to say if what you have will work or not. My guess would be that if nothing is bottoming out in the tail shaft it should be fine. Good luck and keep at it. I think the T56 is well worth the trouble.

V/R

Shakey

-

Senior Member

Originally Posted by

Shakey

Hey Hank,

I wish I had a good answer for you but I don't. I measured my driveshaft length right at 8 inches from the tail shaft to face of pinion flange. FFR said their shortest one was the one you have which is just a bit longer. I went ahead and ordered a custom one after that talk with FFR. I certainly don't know enough about the T56 or drive lines in general to say if what you have will work or not. My guess would be that if nothing is bottoming out in the tail shaft it should be fine. Good luck and keep at it. I think the T56 is well worth the trouble.

V/R

Shakey

Thanks Shakey....after working on the angle of the rear of the transmission it is now flush with that driveshaft to the rear seal. Might try oblonging the engine mount holes and the engine mount to transmission holes each 1/4" if that gets me 1/2 exposed driveshaft back there and angles are OK then I'm good. Agree about the T-56 being worth the trouble, not terribly worried about having to get a driveshaft made either. Will know in the next month or so.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote