-

Member

2021 Ford F150 -> XTF pre runner build log

I'm in!

When I saw the factory five XTF at SEMA I knew it was in my future.

My experience building the GTM into a super unlimited race car that I documented here https://thefactoryfiveforum.com/show...+modifications

gave me a huge respect for Factory Five engineering. In the GTM kit, I was delivered an incredibly capable platform that I and others were able to build into a winning race car AND an insane street car. It was my first ever car build, my first ever race car build, and many more first ever things. The fact that I was successful was all about the foundation I started with and the community here that encouraged me and helped me along.

I have been waiting for years for a V8 raptor like the Raptor R. For me, a V8 is mandatory.

I wanted a truck that was more about the well-rounded experience vs just the bragging rights stat sheet. TRX… its cool and fast, but it’s not what I want.

I wanted a truck with all the nice infotainment features that come in a new vehicle AND next level capability on and off road. For me , cars and trucks are just as much about the total user experience as the numbers on the spec sheet. The user experience is especially important as a daily driver. Ford has invested millions and millions of dollars making the F150 into the best selling truck in America so it’s a great place to start.

Considering what I want , what are my choices? Pay a stupid premium for a raptor R. Wait and hope the Raptor R some day sells at its 109k sticker price which is still kinda high considering what you can buy for $109,000 dollars … or build exactly what I want using the Factory Five XTF… and here we are.

This will be a daily driver toy not just a weekend toy.

Its gotta jump high.

Jumping things is really fun, and having a full size pickup that can fly is unique.

Power needs to be respectable but its not going to be a drag truck. 37 inch tires really ruin your strip times so ill focus on optimizing performance as a pre runner.

Although I'm really far from the desert, the desert is one of my favorite places. Ill move west soon enough so I might as well build the truck ill want when I get there.

Step 1

Find a good F150 to base my build on. Unfortunately Ford does not make it easy to know exactly what you get on a truck, but after doing lots of research I landed on the below.

Requirements

V8- even a stock motor can be boosted to very impressive levels and sounds great

Lariat trim- I think this is the sweet spot for features that will carry over to the XTF

FX4- drive modes and drive train that are helpful in an off road truck

9.75 inch rear end 3.73 gear ratio

Max Tow package – so I get bigger rear brakes, more cooling capacity in the engine and transmission and the heavy duty 9.75 axle

360 camara- this tech is so cool and actually not common on new cars. Ford has a great system.

Sync 4 – I like the giant screen

Pro Power onboard – its handy to have a decent generator built into the truck

I was looking for a low mile truck and something that is corrosion free. I want this thing to fly apart without any difficult rusted nuts and bolts.

I cast a wide net 250 miles around my house and found 5 trucks.

I landed on this one.

10,000 miles on the clock. Got an oil change every 3000 miles according to CarFAX.

It had the panorama roof and nice sound system as a plus.

it has the tow package , but the hitch is pristine... It never towed anything.

It barely had anything in the bed

And the body is absolutely perfect.

I drove it home. 22.6 MPG on the 120 mile drive home. pretty good!

Last edited by kabacj; 07-28-2023 at 04:59 AM.

Reason: Typo

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 5 Likes

-

Member

Now that I found a foundation for my build it was time to collect the parts needed for the kit.

When Ford builds an F150 with the Max tow package where you get bigger rear brakes, enhanced engine and transmission cooling and a heavy duty 9.75 rear axle you also typically get the 36 gallon fuel tank.

The bigger tank is definitely useful when you are pulling a load and getting poor gas milage, however the 36 gallon does not fit in the XT1. In the kit the fuel tank is relocated toward the rear of the truck and mounted perpendicular to the center line of the truck . The 36 gallon is too long to fit across the frame.

Here are the tanks side by side.

[IMG] [/IMG]

[/IMG]

In addition to swapping the 26 gallon tank from a 2015 to 2023 F150 I also needed to order a 26 gallon fuel pump from Ford. Changing the fuel pump will allow the computer to calculate the distance to empty and the sending unit is calibrated to the fuel level of the 26 gallon tank.

Iíll cover the tank swap when we get to that point.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

Most of my time has been spent on hanging the body panels and evaluating what needs to change as I put gen 13 F150 body panels on a Gen 14 cab.

With the body panels in place, I was able to install the headlights.

Factory five include a harness to switch between the stock wiring and the aftermarket headlights.

Here is a shot of the DRLs in the day.

And at night

Last edited by kabacj; 08-30-2023 at 05:21 AM.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

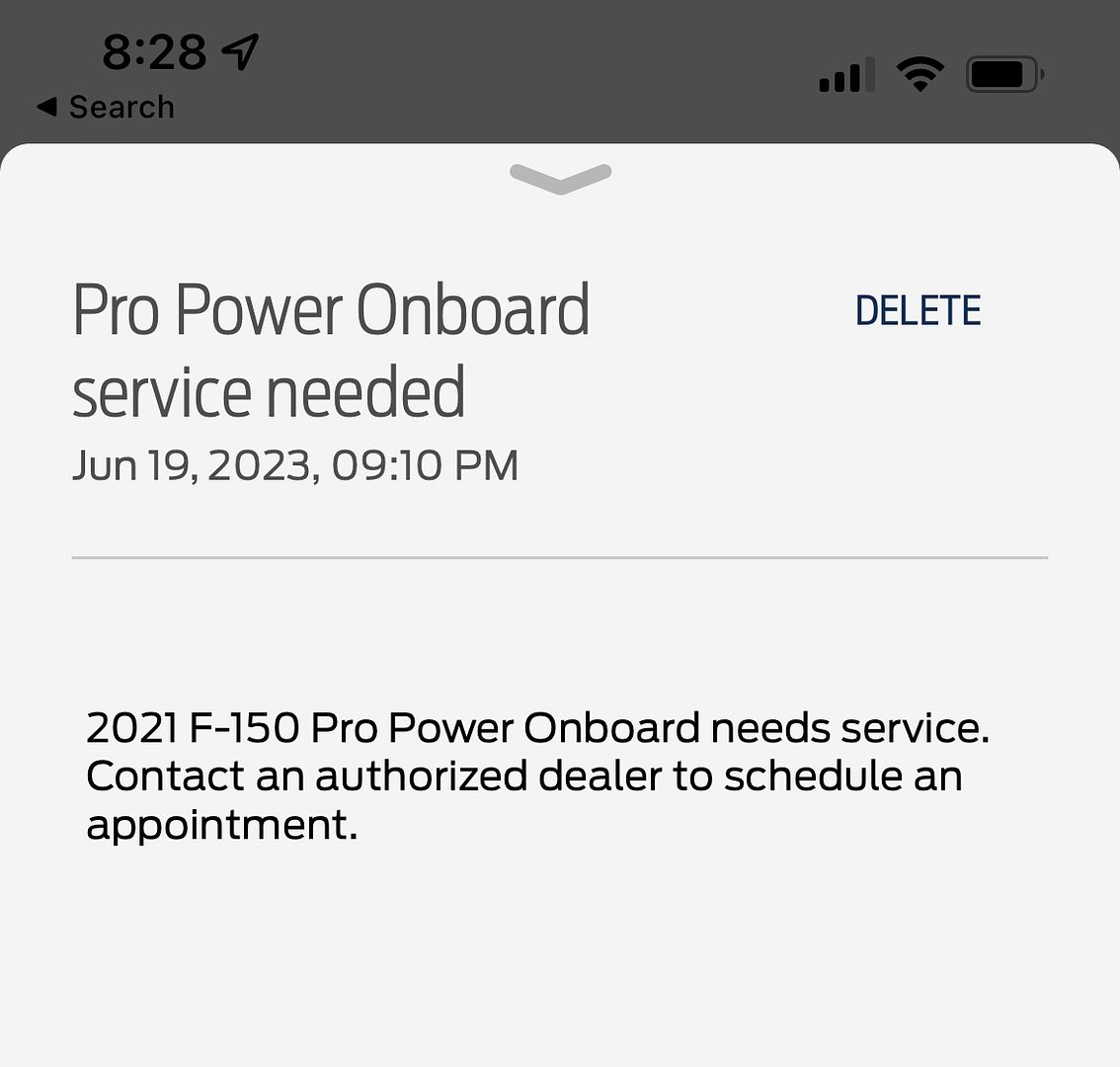

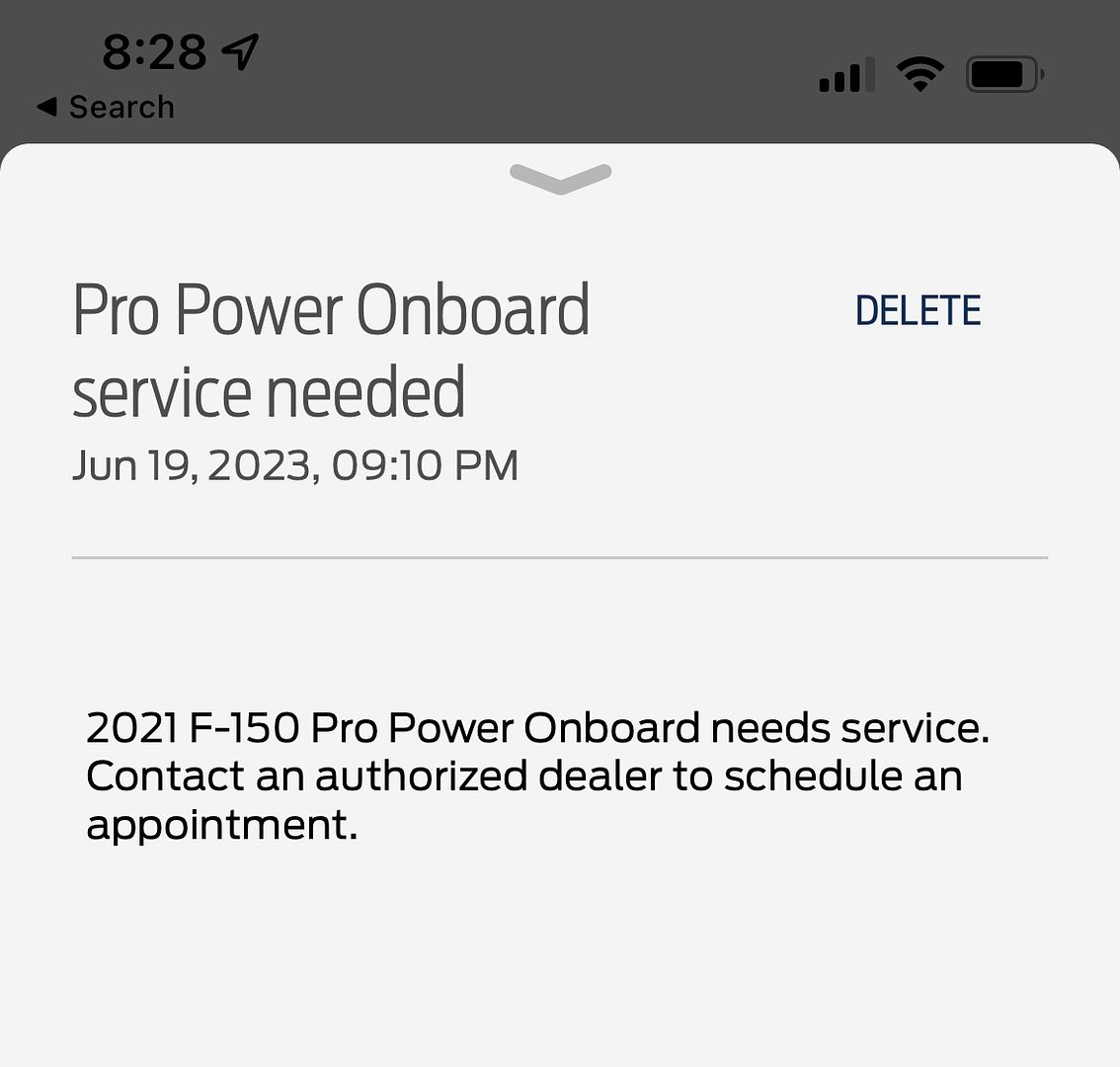

I like the idea of having a generator along with me at all times so I looked for an F150 with the pro power option. Pro power gives you two outlets with 20 amp service in the bed.

In order to get the bed off these accessories as well as the LED bed lights need to be removed.

[IMG] [/IMG]

[/IMG]

The thing about any of the accessories and gizmos on this truck is everyone of them needs to be moved over to the XT-1 build or the truck complains either on the dash info screen or via the Ford Pass app or both.

[IMG] [/IMG]

[/IMG]

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

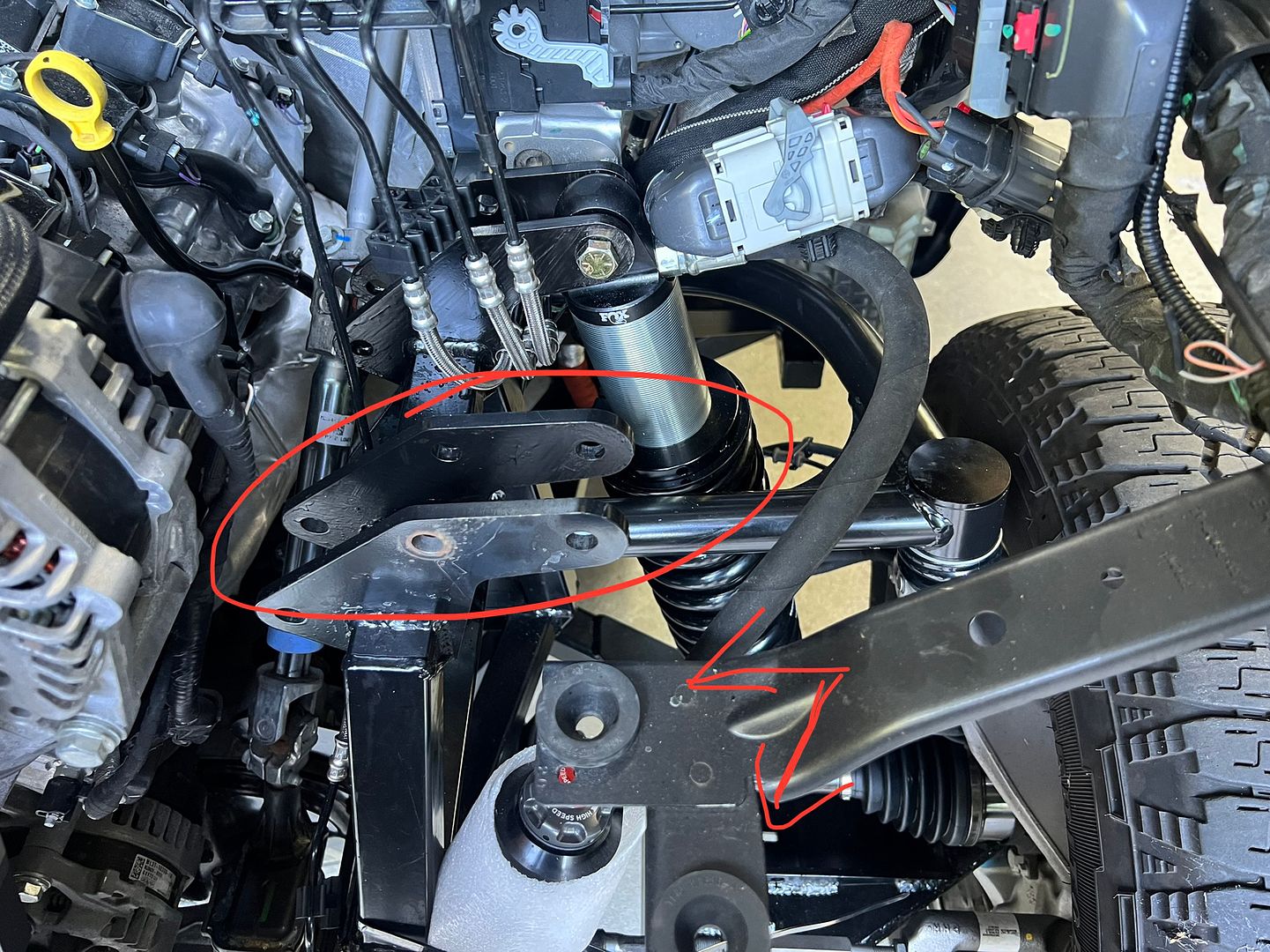

In order to build a more capable truck than anything you get from a major manufacturer, it’s necessary to start over with a new frame. The frame needs to prioritize articulation as well as have the ability to take advantage of a race quality off road suspension.

One feature that takes the truck to the next level is a second shock called a bypass shock. Here is an example

Using a shock like this you can tune each portion of the travel of the shock.

Each section of the travel has its own damping adjustment that is completely unrelated to the travel before or after.

Many traditional mono tube shocks are limited by a common set of valves that limit how drastically you can adjust travel throughout the stroke. Especially without physically opening the damper and changing valve packs. Using both a standard mono tube shock and a bypass shock at the same time it’s possible to blend the best of both worlds. The mono tube provides a fixed damping curve and the bypass shock provides a stepped curve where it’s possible to tune each section of the stroke. The bypass shocks allows adjustment of each portion of the stroke with adjustment knobs outside the shock. Changes can be made quickly on the fly for each step of the travel.

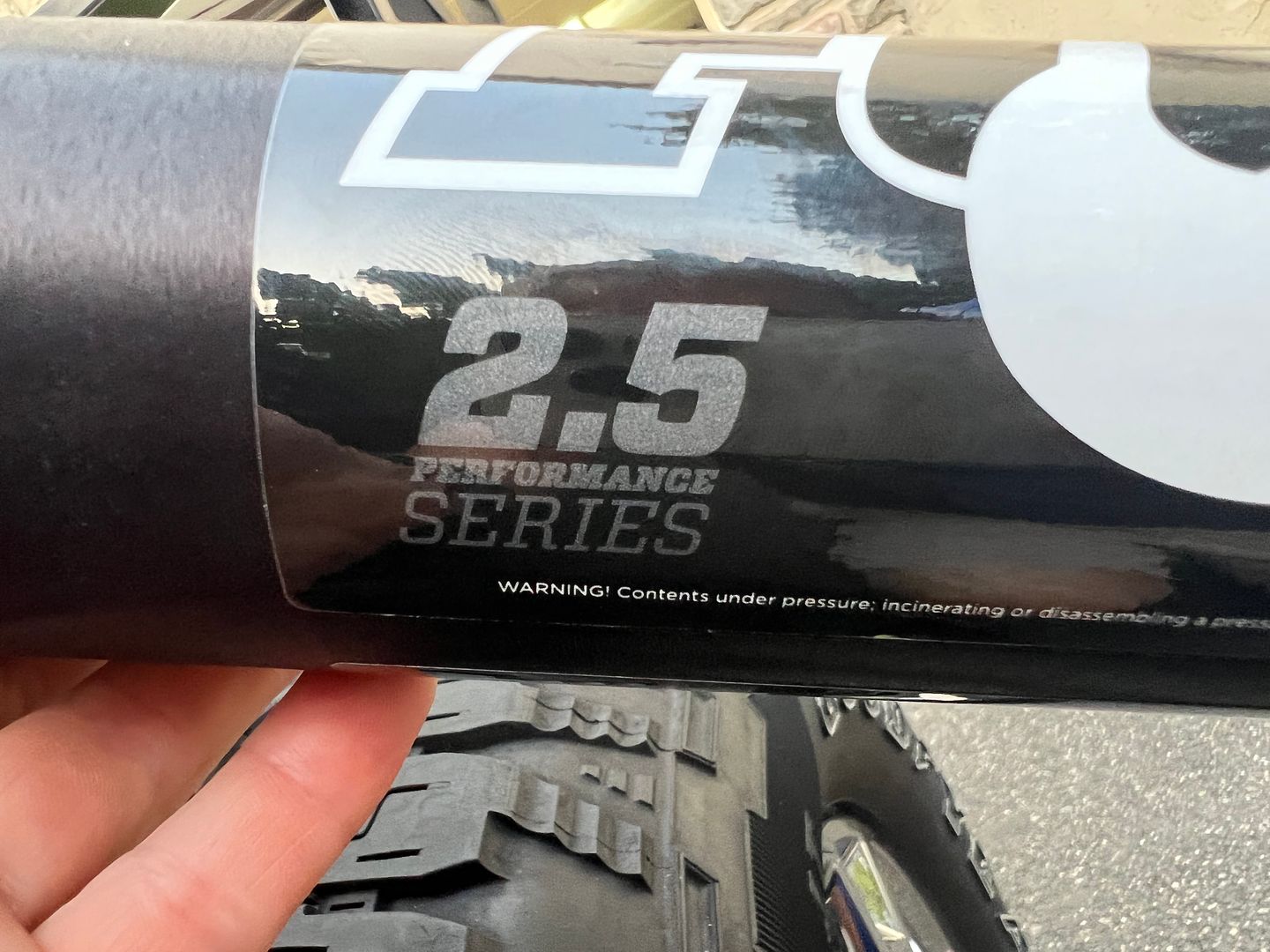

Of course if you go this route ( as I will) it’s necessary to re tune the shock sent with the basic kit. Since the bypass shock will do part of the damping work, it’s necessary to remove some damping from the stock factory five tuned Fox Shock. Luckily the Fox 2.5 dual compression adjustable shock is fully rebuildable and tune able using basic hand tools and a compressed nitrogen cylinder to recharge the shock.

I plan to both test the performance of the standard kit built on the Gen 14 F150 as well as build and test the next level performance afforded by a bypass shock.

Finally the frame will accept air bump stops as well.

Air bump stops are yet another shock to help you control that last bit of travel before the shock hits bottom.

The great thing is no matter where you want this truck to be from a performance standpoint the frame is already built to accept the upgrade.

I can’t wait to start testing!

Last edited by kabacj; 07-28-2023 at 09:17 AM.

Reason: Clarification

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

I solved a mystery from a few weeks ago. I was looking for an M9-1 bolt for the Ford 9.75 inch differential housing. Using my tap and die set I sized the bolt to be 9mm but I could not find a thread pitch that matched and I guessed the thread pitch was 1MM. Of course there are no 9M-1 bolts to be had anywhere except a few titanium bolts listed on Amazon.

Turns out my problem was I didnít have the tap and die that matched the bolt.

Somehow I have survived using my tap and die method of sizing nuts and bolts for many years, but this project has stumped me a few times.

I found a good solution.

I thought I had every tool under the sun, but this one really helps. Now I know the size of the bolts that go into the Ford 9.75 differential cover.

5/16 - 18.. That was easy!

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

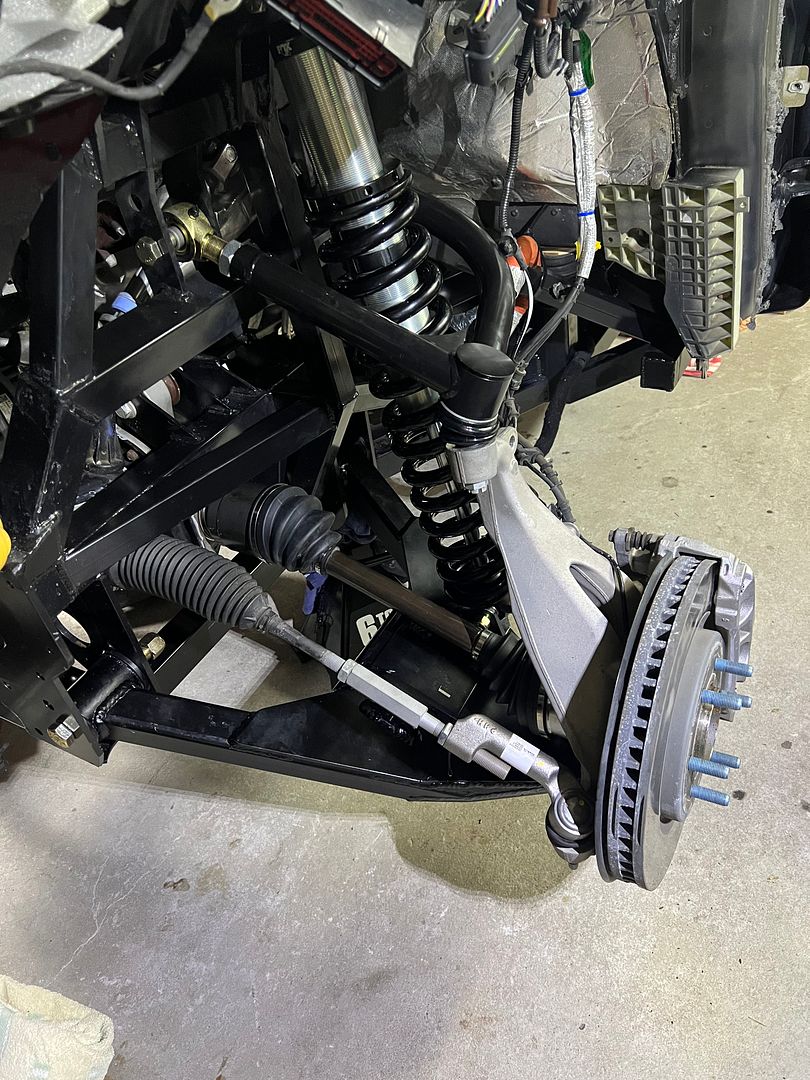

Since I plan to do lots of testing and adjusting of the suspension I figured i need to outfit myself with the proper tools. One tool thats very helpful is a preload adjuster.

Here is the preload adjuster aka spanner wrench from FOX. Note the part number. 803-00-832 this preload adjuster fits the Fox 2.5 DSC damper included with the kit.

The adjuster attaches to the top collar on the shock like this allowing you to crank down on the spring increasing or decreasing the static ride height. Right now I just have the adjustments at zero pre load to see where everything ends up.

The other thing needed for the next step is the CV axles. Factory Five had longer CV axles made to allow for both wider track as well as more travel. You can see the increase in length on the Factory Five CV axle compared to the ones removed from the stock F150.

Last edited by kabacj; 07-31-2023 at 07:11 AM.

Reason: Typo

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Member

-

Member

Looks like Road and Track came out with an article on the XT1 yesterday

http://https://www.caranddriver.com/news/a44298958/ford-f-150-factory-five-xt1-kit/

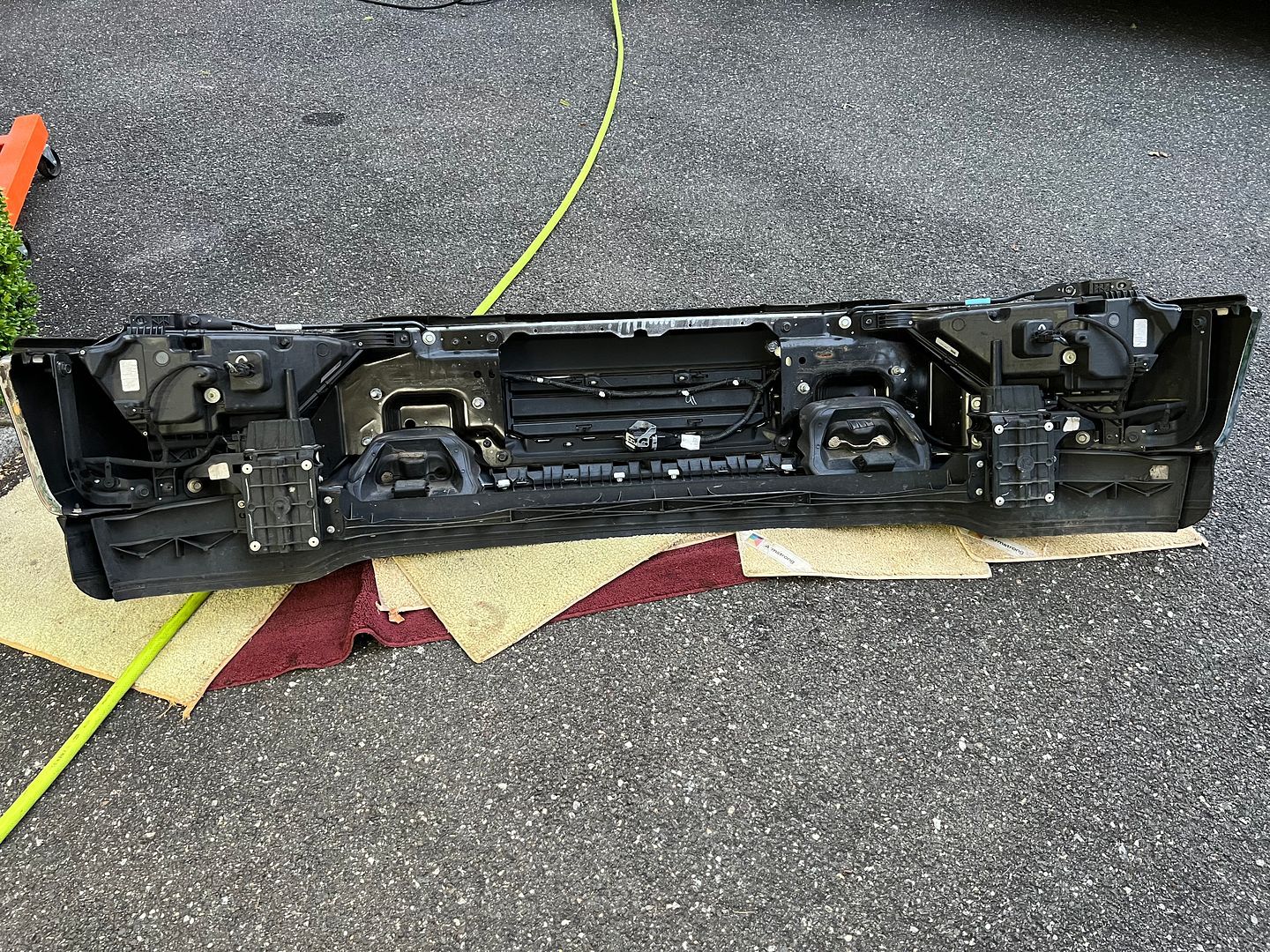

The next AM was a work day for me so my son was responsible for completing the front end tear down.

In no time at all I got a text with these pictures.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

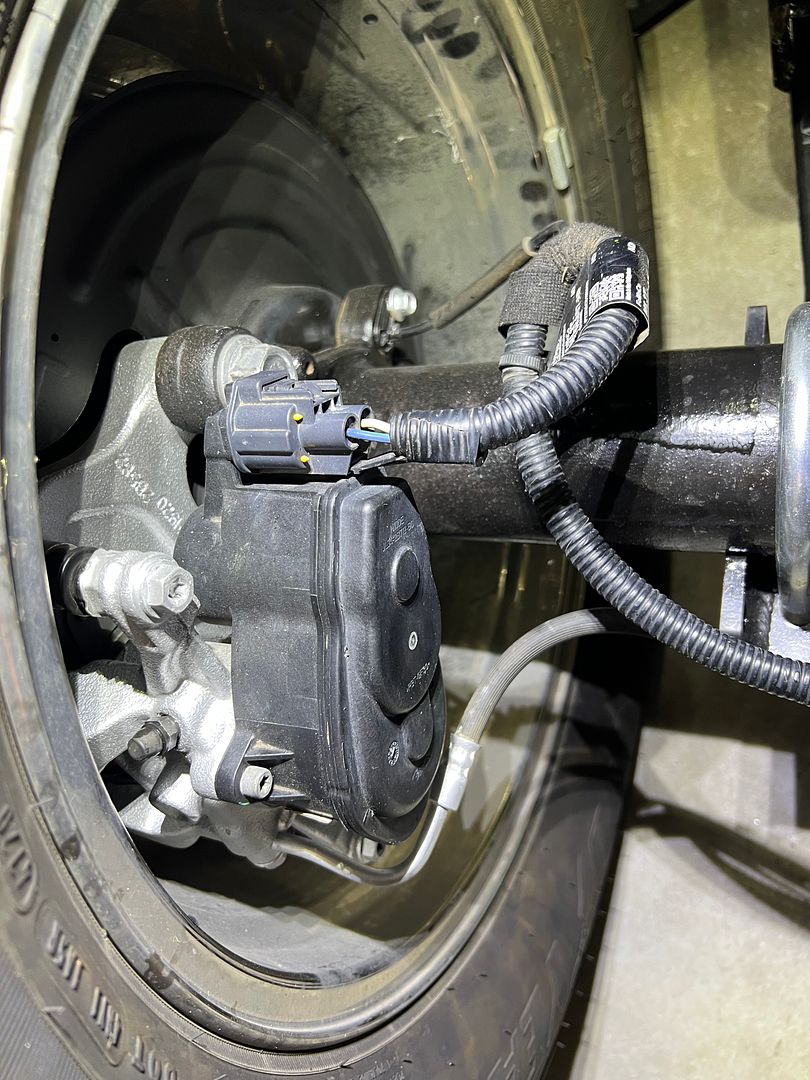

After pulling out the grill you need to remove and save the grill shutter motor for re attachment later.

I forgot to take a picture with it installed, but this is where it sits in the shutter mechanism

[IMG] [/IMG]

[/IMG]

the splines in the motor fit into the drive axles that move one left and one right shutter. All shutters are connected by a pretty elegant mechanism that snaps on and off easily

Because i have been traumatized by plastic parts that break when you try to disassemble them I was a little scared to do this , but I tell you, ford has come a long way with their plastic materials science. The shutters are just pliable enough that you can bend the shutter vain in the middle by pulling on it and prying at the edge and it just pops out without breaking!! What a concept!

pry here and bend the shutter from the middle and it pops right out.

_IMG_9990.png?width=1920&height=1080&fit=bounds)

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

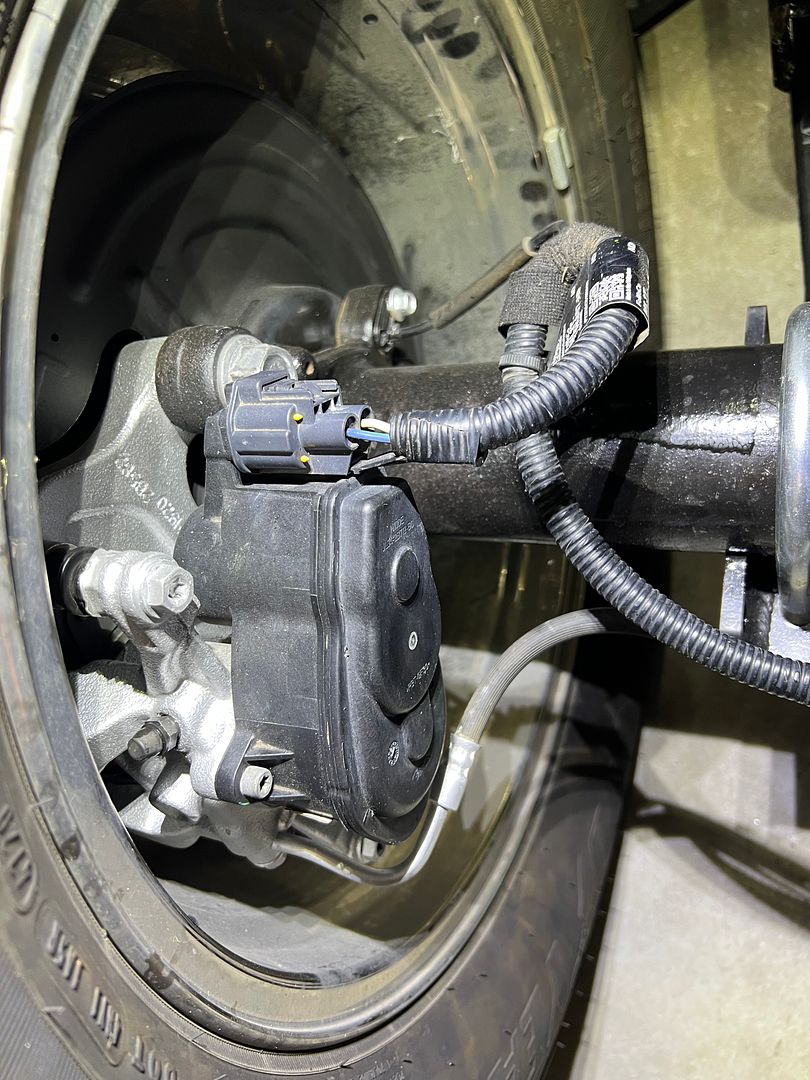

First question for the group.

I am being very careful to make sure to keep track of anything that is plugged in because the trucks computer seems like it does an inventory of every item that it expects to be connected at startup. I also notice that it does a verification that sensors are in range. That's a reasonable thing to do..

one of my tasks today is to plug everything back in and check the truck with a scanner and verify that the truck thinks everything is OK. After that the motor and trans come out and the cab comes off.

oddly i found this one plug that does not go to anything. The plug actually goes to the white block off which is attached to this bracket. The plug is right in the area of the headlight and if it did plug in somewhere it seems like that's where it would reach.

anyone familiar with what it is? unless you took the truck apart you probably would never see it. My google searches come up dry.

Last edited by kabacj; 06-24-2023 at 07:27 AM.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

Thanks for the info Erik.

Your videos are also helpful as I can see how things are setup in the GEN 13 F150 vs Gen 14. That of course and a lesson on how to fit two turbos into barely enough space.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

I cant even imagine taking such a beautiful truck apart. I would guess you can recuperate some of the cost by selling off everything you don't need?

Mike

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

Originally Posted by

michael everson

I cant even imagine taking such a beautiful truck apart. I would guess you can recuperate some of the cost by selling off everything you don't need?

Mike

Hey Mike,

Yeah I think I can sell off the bumpers, bed, fenders stuff like that because those are the parts you most often damaged in a fender bender. All the parts are pristine condition so they should make someone happy when they swap out a damaged part.

I'm not going to lie saying It doesn't hurt me a bit to take apart such a nice truck . The truck is wonderful , but it really needs something... a little spice.

I think this project is really going to solve that problem. Haha

Last edited by kabacj; 06-24-2023 at 06:47 PM.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Member

-

Member

Because i am paranoid that somehow I messed up the electronics. The truck complains a lot when moving it around without all the sensors attached. For example, it will not go into drive when the hood open sensor is disconnected.

I plugged everything back in for a test.

_IMG_0016.png?width=1920&height=1080&fit=bounds)

Success!

I also got an accessory backup camera like you would use on the back of a trailer or camper shell. This will allow me to retain the 360 camera with the tailgate on or off.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Definitly sketchy! But I'll give you points for ingenuity! You have my attention!

Higgy

MK4 #11012 picked up 04/16/24

351W, 3 link, single roll bar

MK4 #10616 picked up 4/10/23

302w, 4 link, 17's, dual roll bar SOLD

MK4 #9759 picked up on 4/3/19

351C, 3 link, 17's, dual roll bars SOLD

-

Member

Originally Posted by

Higgybulin

Definitly sketchy! But I'll give you points for ingenuity! You have my attention!

Higgy

Haha. Higgy

Both my son and I had nightmares on Sunday night that we would wake up to the truck on the pavement on Monday AM.

But to be honest now that the monument to the F150 greets me every AM on my way to work and when I get home I'm getting used to the idea of having the truck body up there.

Itís actually very very stable.

If this giant boat is ok why isnít a tiny truck body ok?

Just think of the wood platform as a giant jack standÖ seems kinda normal nowÖ maybe?

This is how I convince myself stuff like this is OK. Ha

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Originally Posted by

kabacj

If this giant boat is ok why isn’t a tiny truck body ok?

Is that your boat? Now you've got my attention! She's a beauty!

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Member

Originally Posted by

JohnK

Is that your boat? Now you've got my attention! She's a beauty!

Hey John

No I wish that was my boat. I have a Catalina 22 with a swing keel. I lifted that boat 4 feet in the air to drop the keel and repair it. Thatís why I was pretty sure I could lift an aluminum shell a few feet up. The boat still floats so hopefully the truck lands safely too.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

MAJOR mile stones this weekend.

First start and the truck moved under its own power and stopped!!

Of course I press the start button for the first start and the battery is almost dead. Ha. But 5 min on the battery booster it fired right up.

One of the amazing things about this Ford Performance (whipple supercharger) install is that you donít flash the ECU. You simply put in the hardware and fire it up! That was a bit scary to be honest. The ECU quickly learns the fuel air mixture and you are good to go. Pretty amazing really. No smell of un burnt fuel. No bad habits noticed so far. I really canít believe it was that easy to add so much hp. The super charger kit still comes with the Whipple tuner and OBD2 connector so you can monitor the system as well as make modifications in the future. Very nice.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Not a waxer

-

Post Thanks / Like - 0 Thanks, 5 Likes

-

Member

Originally Posted by

Jeff Kleiner

Hey John...just sayin'

Jeff

Haha. You got me Jeff for sure. I originally planned on taking the truck down off the stand I had casters and plywood pads built into the lifting frame but. It kinda looks good to me in the driveway.

Nobody has mentioned anything to me about it, but Saturday Iím sure they all will come by to see whatís going on this time.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

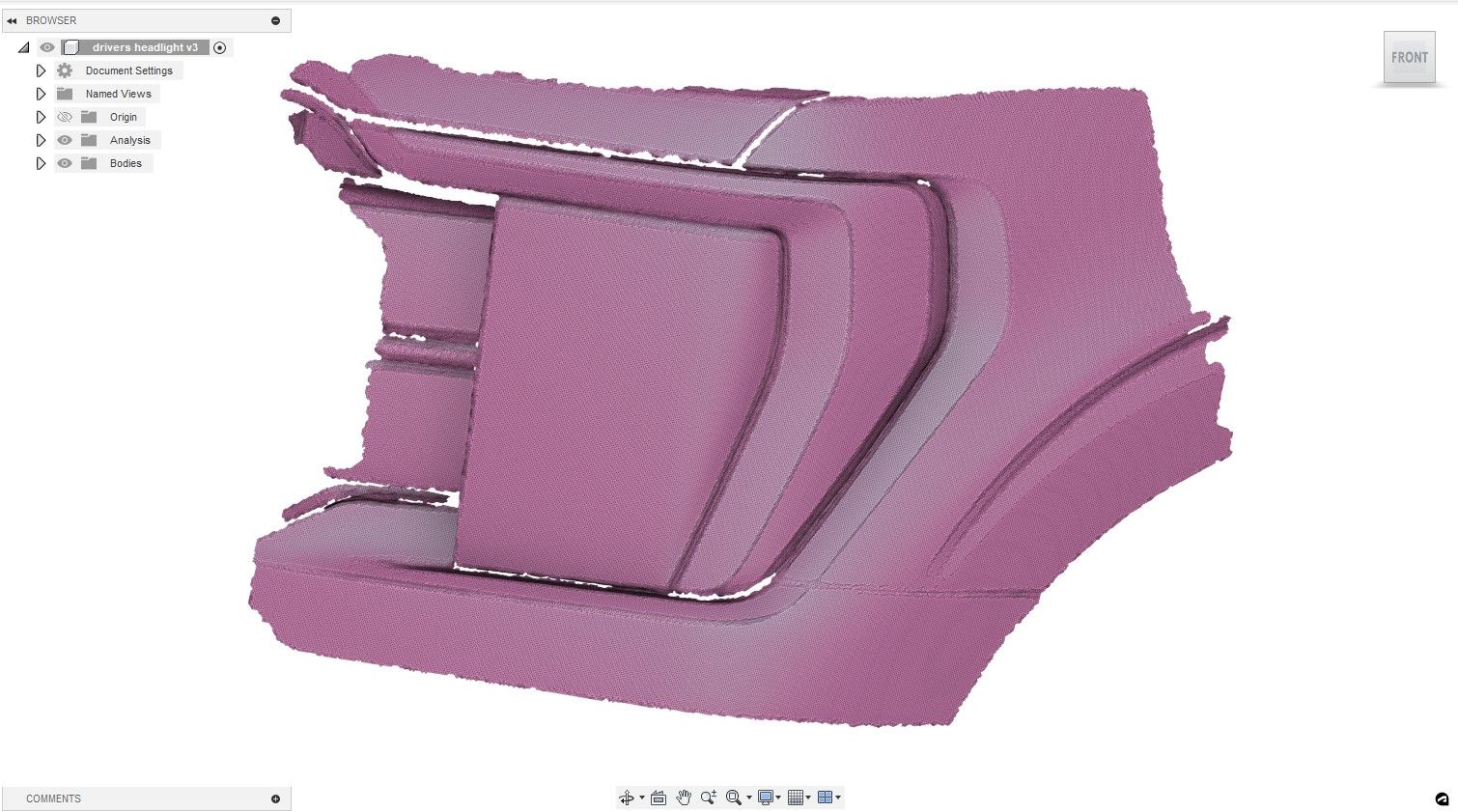

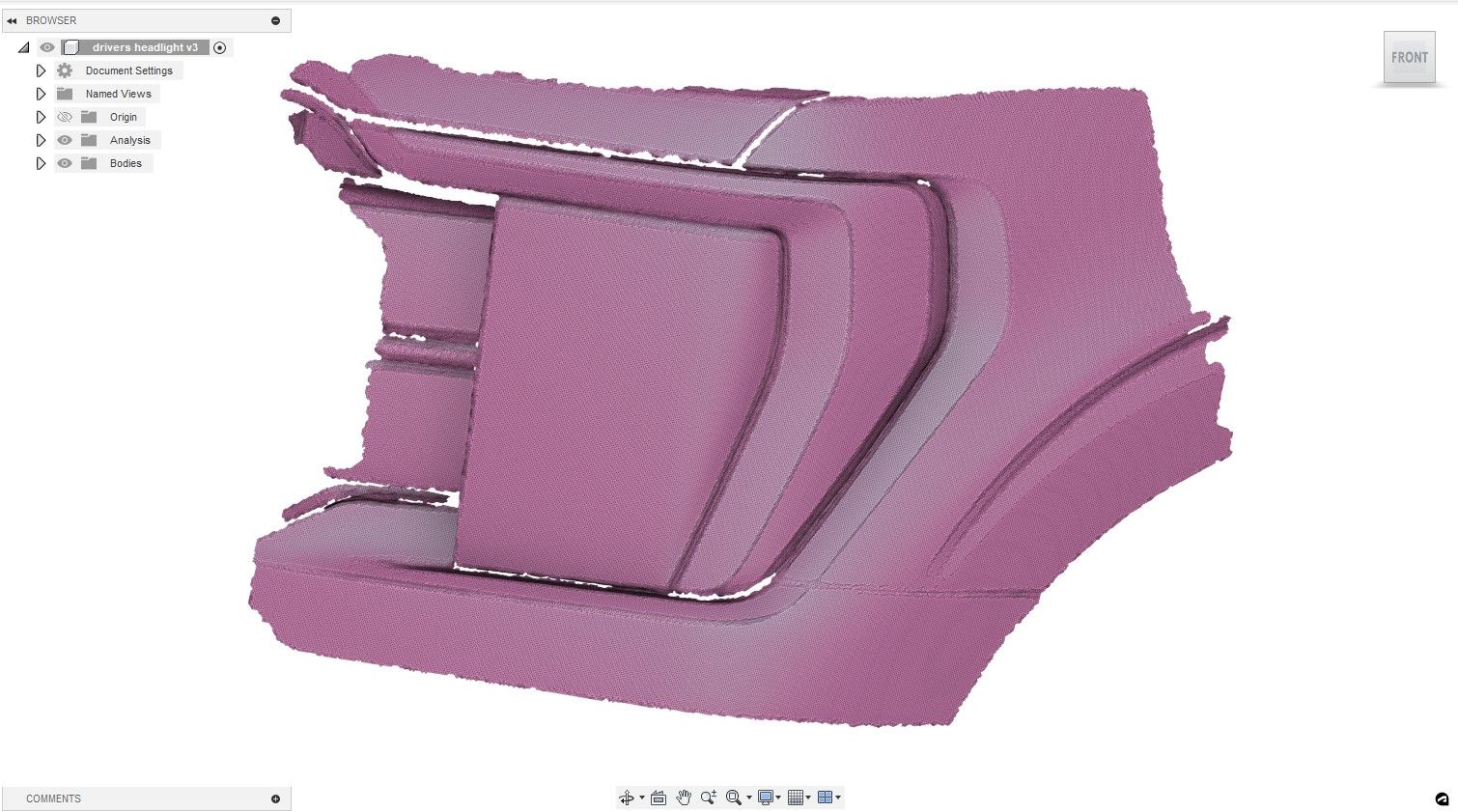

The other big difference between Gen 13 (2015 to 2020) and Gen 14 (2021 to 2023) is the headlights and taillights.

I am torn between keeping the gen 13 look and changing the truck to look like a gen 14.

There are two major concerns. First is the wiring and integration with the computer systems in the truck. The tail lights have the blind spot detection system built into the taillight housing as well as possibly some integration into the trailer backup assist gizmos. The headlights are LED and have the computer controls and low amperage wiring associated with those.

Of course the headlights and taillights are a different shape on the gen 14 compared to the gen 13 the XTF was based on.

I have a few ideas on how i can solve the bodywork. I took some 3d scans of the headlights and tail lights

I could mill out or 3D print a mould that looks like the gen 14 bodywork, make a fiberglass part and then graft it into the factory five bodywork. Im not sure what will be fastest and most accurate.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Member

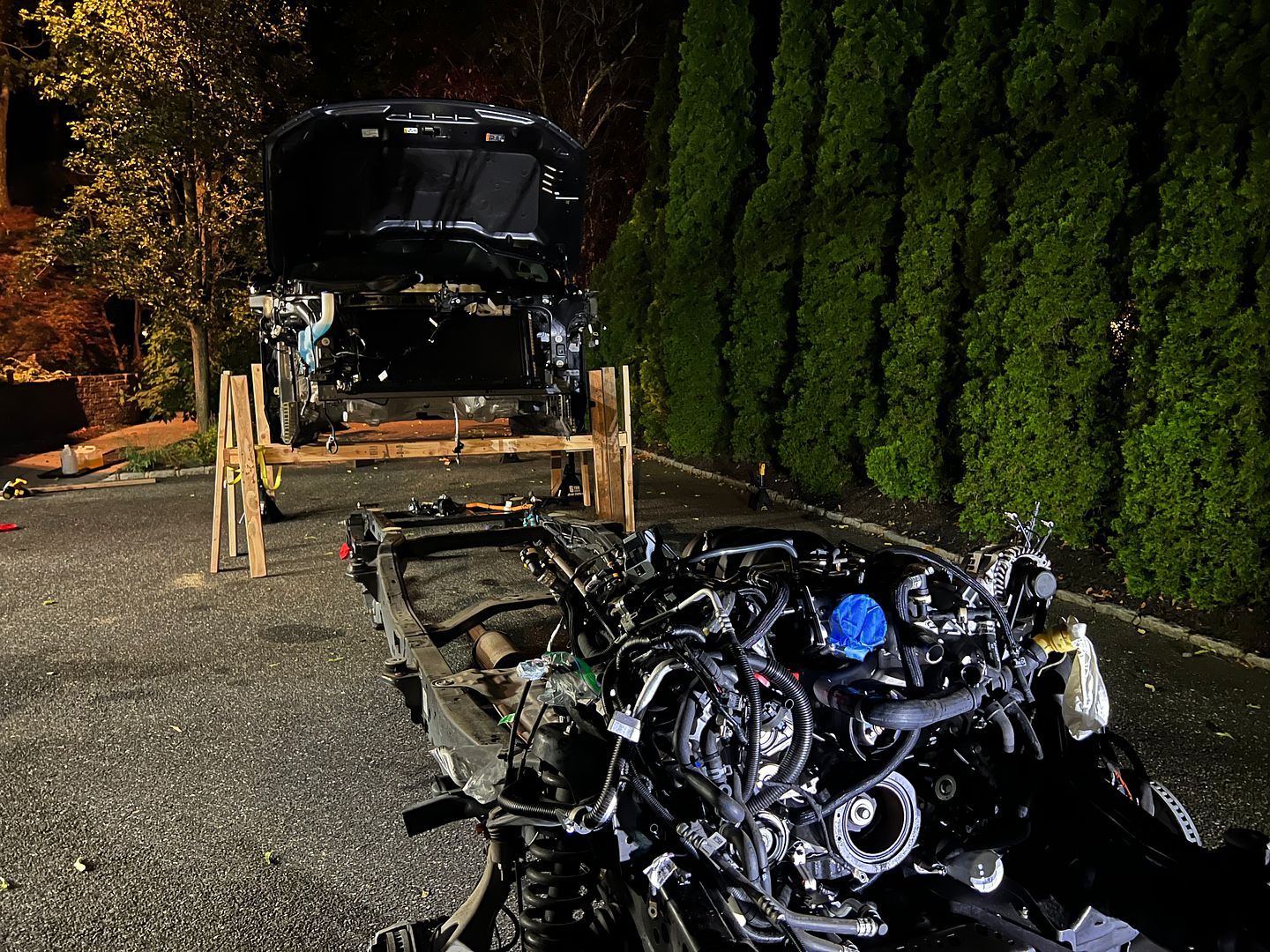

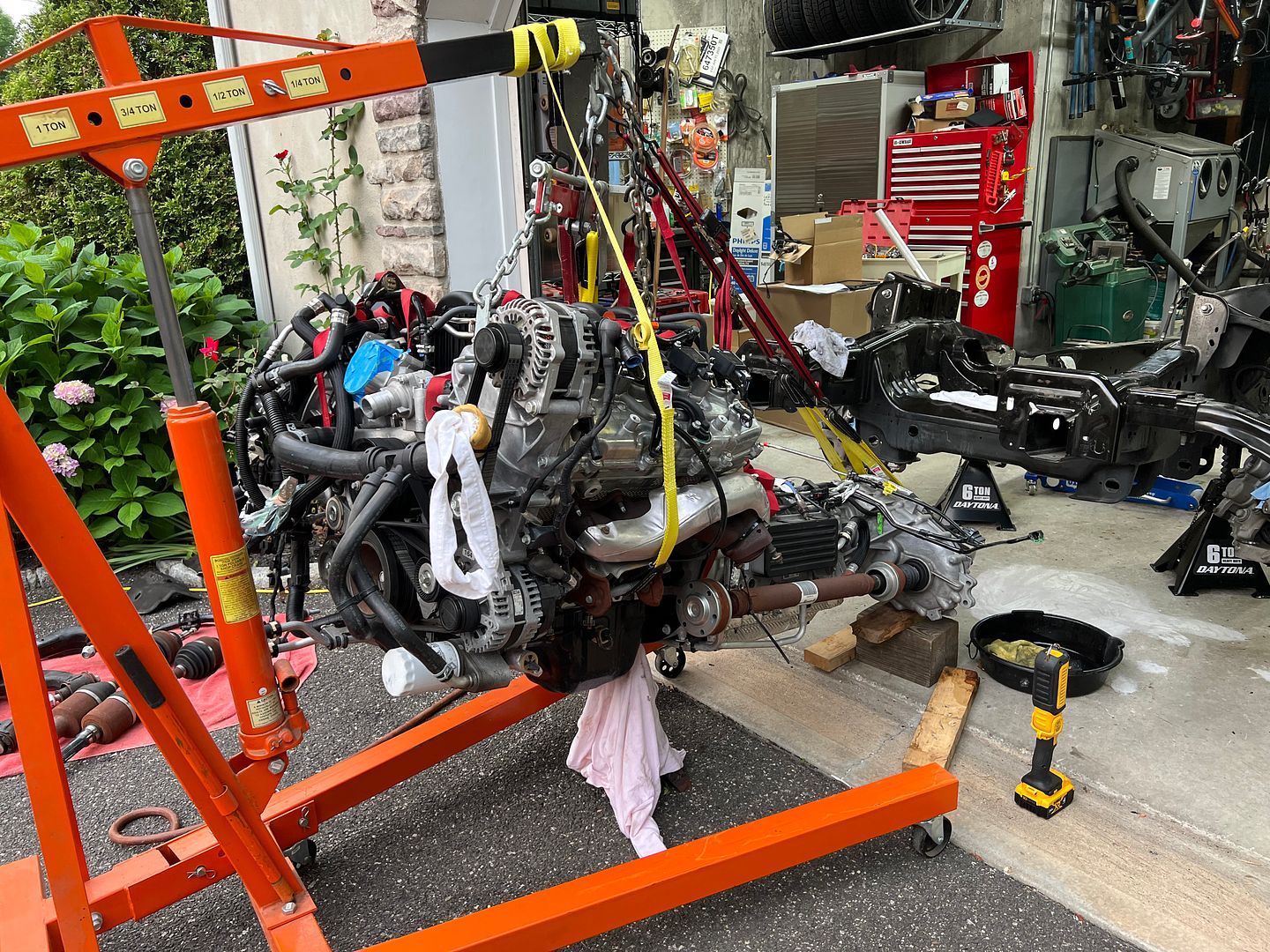

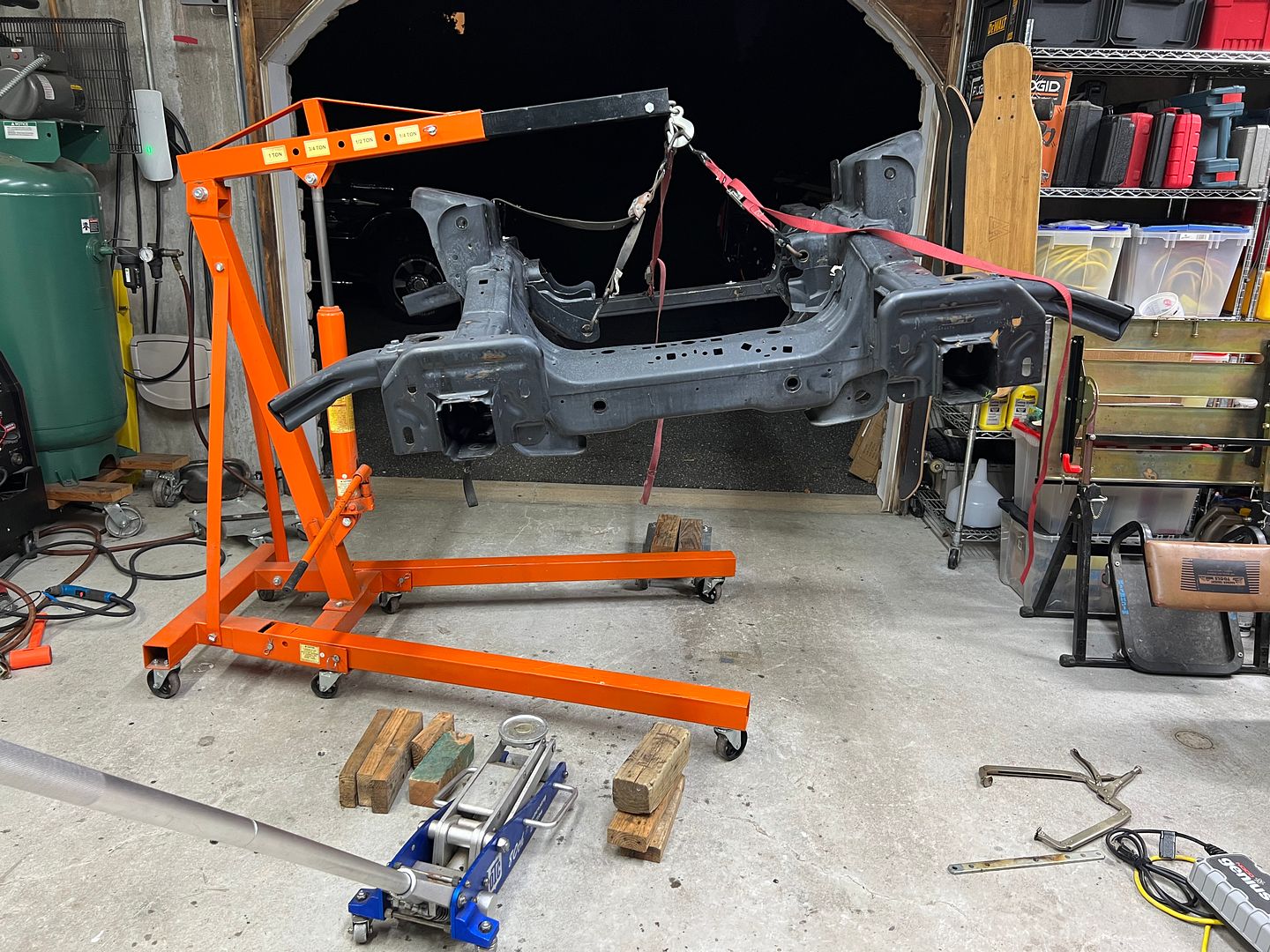

So itís 10.00 at night on Sunday and we got the motor and frame out from under the body. I under gunned the lifting frame. Making a 6.5 by 8 foot rectangle using only one 2/4 allowed too much flex for my comfort, so I ended up laminating another 2x4 inside the original frame to make everything much stiffer mid lift. That and figuring out how to get the frame / motor as low as possible and how to move it all around took some time.

But we got it done.

It was too late to drop the body down on to the casters like I had planned so itís going to stay there for a week.

The next step is to free the motor/ transmission and front differential from the frame.

I plan to lift the whole assembly up and drop it into the factory five frame that should arrive on Friday.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Member

Today is the day!

Customer frame number two is on its way from Factory Five right now! The crew left at O dark 30 to beat the holiday traffic. I can’t wait!

Last edited by kabacj; 06-30-2023 at 06:57 AM.

Reason: Typo

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Member

It is very different working on a rolling computer vs the mostly analog factory five cars we are used to. The computer has something to say about just about anything you do or touch.

Here is an example. I had not yet connected the braking system when I started the truck for the first time. Of course to start the truck that means connecting the battery. Once the battery is connected the truck immediately starts complaining about brake fluid levels, the fact that the braking system is inoperable. Of course the accident avoidance system cant work because the pre brake assist cant work so it complains about that.

Ok no problem (OK,OK,OK) to all the codes. Then this is the best, The truck immediately puts on the electric parking brakes and refuses to take them off. The buttons don't work!

Of course this is probably a good safety measure. If you don't have hydraulic brakes itís probably not good to move the truck. Keep the electric brakes on.

But I want to move the truck. Nope you cant.

Well F150 computer I know how to fix you. Iíll just unplug your connection to the electric brakes. Letís see how you deal with that.

Well I won that battle. Now I can push the truck.

OK F150, Iím going to move you wether you like it or not. Iíll just put the truck in neutral. Nope you cant. The gear shifter is controlled by the computer. It isnít physically connected to anything. Human, you can move the gear shifter all you want . We are in park.

OK F150, luckily the ford engineers thought of this and have a way to take the truck out of park even if the computer is dead.

Pull this little orange tab and we can physically take the transmission out of park via a cable connected to the transmission.

NOW i can move the truck. Wow, that was a new experience.

When computers take over the world, at least you will know that you will be able to drive your factory five Cobra, hot rod, coupe, GTM, hot rod pickup, or 818. Your Factory Five XTFÖ the computers own that one.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Member

Delivery Day!! Woo hoo!

The guys rolled in bright and early which was excellent. Some quick teamwork and we had all of the boxes unloaded.

Next we rolled the frame off the flatbed adjusting the loading ramps to account for the offset of the casters.

In no time we were unloaded. Time to get building!!!Ö oh after I go to work. I really need to adjust my priorities.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

_IMG_9971.png?width=1920&height=1080&fit=bounds)

_IMG_9990.png?width=1920&height=1080&fit=bounds)

_IMG_0016.png?width=1920&height=1080&fit=bounds)

_IMG_0719.png?width=1920&height=1080&fit=bounds)

_IMG_0052.png?width=1920&height=1080&fit=bounds)