As most of you know I did a Polycarbonate rear window. We'll I have had it in for about a year now and have had no problems at all with heat or scratches. The one problem I did have was my insufficient preperation of the surface I back painted black. I used a PC that is hard faced on both side for scratch resistance and UV protection. So sanding it was most difficult and I apparently did not do a good enough job because when I glued it in I developed air bubbles where the paint pulled from the PC. This happened immediately when I installed it and then got worse over time.

The bubbles bugged me too much so I pulled the window to try again. HOLY COW!!!! What a job to get that window back out. I wound up de laminating some of the build up I put on the hatch to get the shape right. And I'll be cutting and fitting a new back window because I damage the original with the heat gun. Heat does nothing to soften the urethane adhesive.

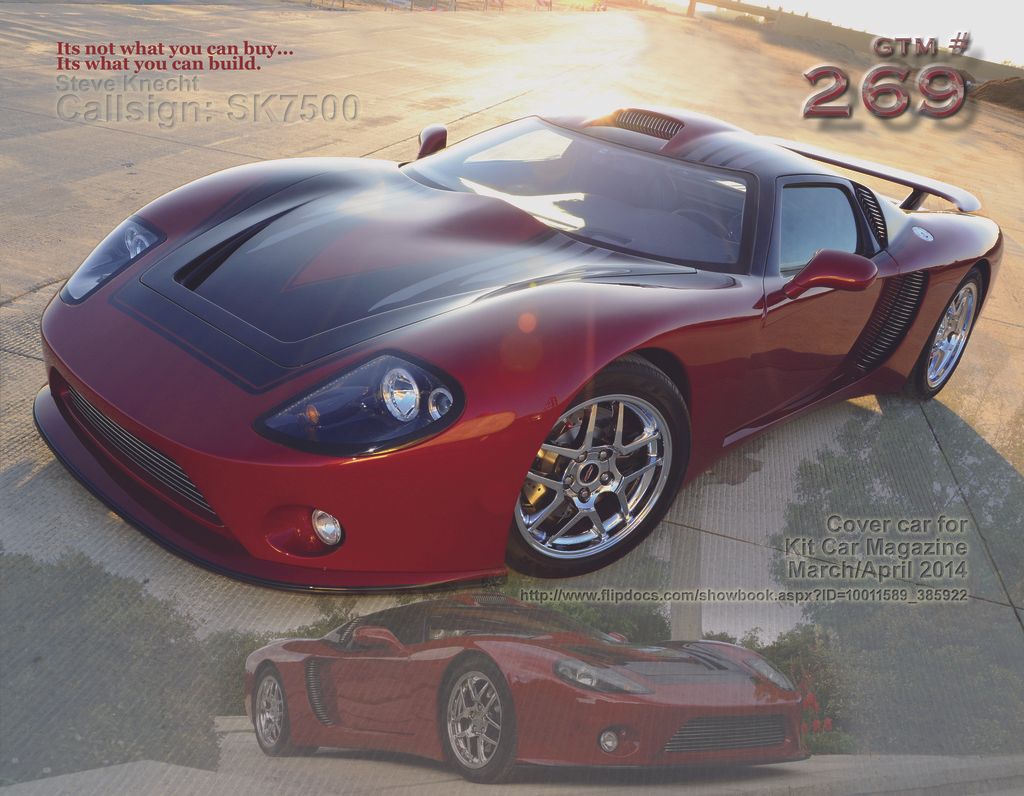

So I include a couple pictures for you to look at to remind you "Prep, Prep, Prep" before you paint!

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

. I was thinking of just using a paper template made from the glass window/ the opening in the car.

. I was thinking of just using a paper template made from the glass window/ the opening in the car.