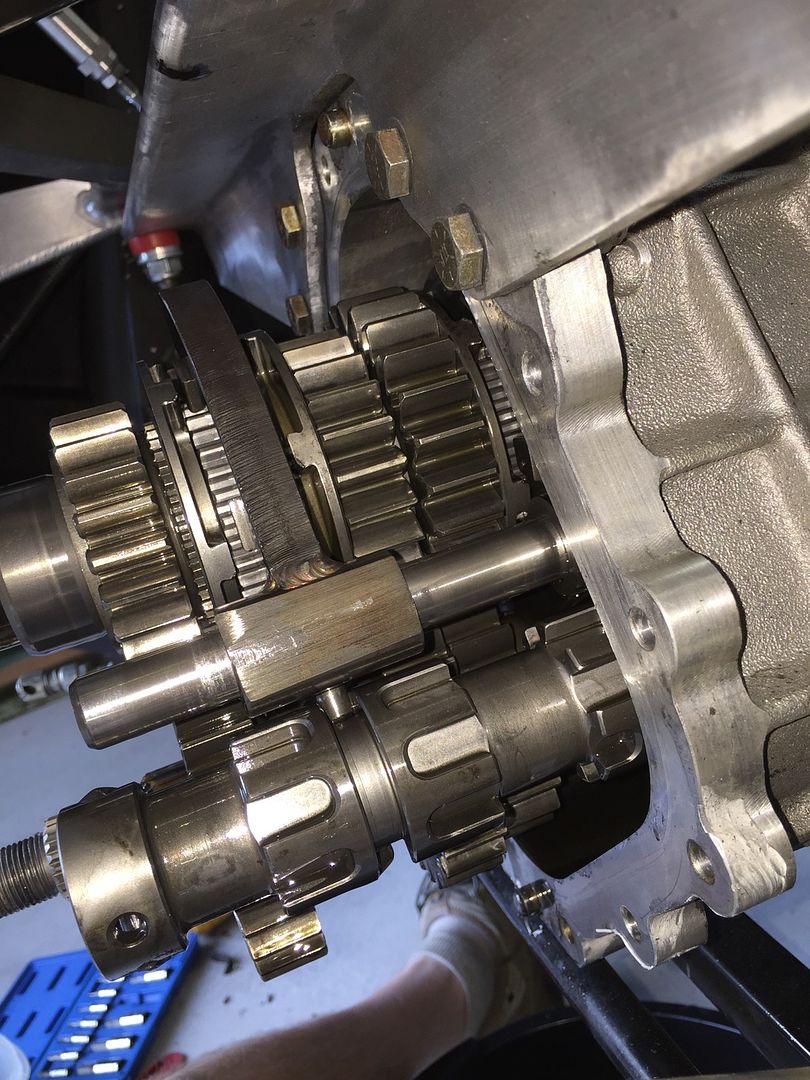

That all depends on how quickly I can get the transaxle back into adjustment

Maybe as soon as June 5, but since I was unable to get the endoscope into a position where I could see anything wrong. A tear down is planned for this weekend. Lots of family stuff planned too so it's going to be a difficult task to fit in.

Maybe I'll just forfeit sleep to get it done.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

I look forward to reading how things work out at the track.

I look forward to reading how things work out at the track.

.

.