I had a feeling that I was subject to 3 different custom parts makers having all having tolerances that added up to a problem.

It looks like that is exactly what happened.

My main suspect was the clutch. However after walking through and measuring all of the parts with Kennedy Engineering on the phone. They are all with in spec. When I inspected the clutch it all seemed to be working properly. Each plate and steel surface had scuff marks from engagement. The clutch was clearly clamping when I pulled the transaxle out. My problem was that it was slipping with out fully engaging.

I quickly realized that the problem was not with the clutch function, but rather the relative placement of the clutch between the motor and transaxle.

When the transaxle was installed the throw out bearing was permanently pressing on the diaphragm spring . Even when I adjusted the clutch throw out fork to its max out position, It was still slipping the clutch.

I did not realize this was the case when I installed the clutch and tested for some air gap between the throw out bearing and springs It sounds like there is air gap. You can hear a click as it he throw out bearing hits the diaphragm springs. But in fact the throw out bearing was backed into the bearing guide mounting bolts and I was hearing the click of free play in the assembly that moves the throw out bearing. You can not see the air gap between the clutch and throw out bearing on this transaxle as the bell housing does not have an access window.

I did some careful measurement and confirmed the problem.

There are a few ways I could think of fixing this.

There is quite a bit of material on the back side of the area that the flywheel mounts to the crank shaft. That could be machined to bring the clutch assembly closer to the motor. Or the guide that the throw out bearing rides on in the transaxle could be moved back into bell housing OR I could simply make sure the throw out bearing goes back all the way back on its travel by trimming the bolts behind it.

As I did not really need that much more clearance I opted for the easiest and fastest fix first.

First I removed the lock washers. That got me a few tenths. Then I turned down the heads of button head allen bolts. I was able to make them thin, but I was concerned that I could easily strip out the allen head since I did not have a lot of material left. I decided that I would just turn down a normal hex head as that would be more sturdy and less likely to strip.

With everything optimized and adjusted I was able to get a reasonable air gap

If you don’t have one of these I suggest you get one.

It’s a sealed usb camera with a LED lights. I hook this one to a piece of aluminum welding rod. And for 25 bucks I have a GREAT way to trouble shoot things without tearing them apart. For the transaxle I can fish the camera into the bell housing via the opening for the starter.

I was able to inspect the clearances after some creative bending an twisting of the welding rod.

Here is a picture of the back of the throw out bearing. I can confirm its bottoming on the bolt heads I turned down as it travels away from the clutch diaphragm spring.

Here is a view of the air gap. Looks like enough. It looks bigger in the picture as we are super zoomed in.

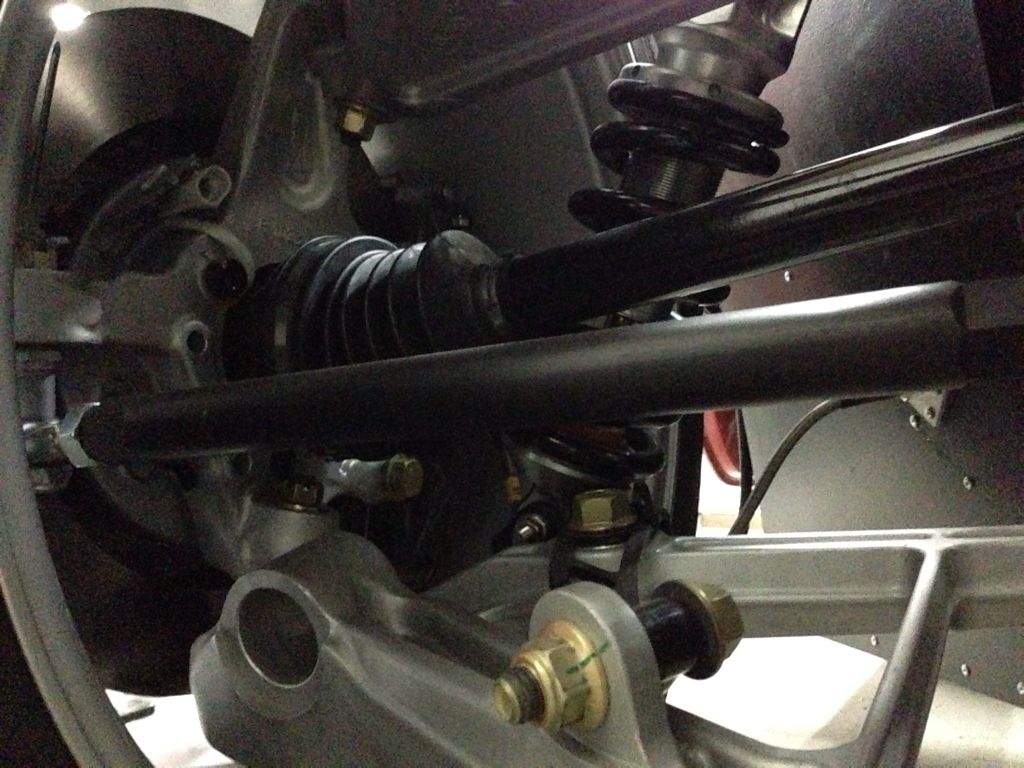

Now that its all sorted im optimizing a few of the cable routes and the position of the slave cylinder, and ill try to do a test run this week. Hopefully that solves my problem

John

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote