Hi GTM Racer.

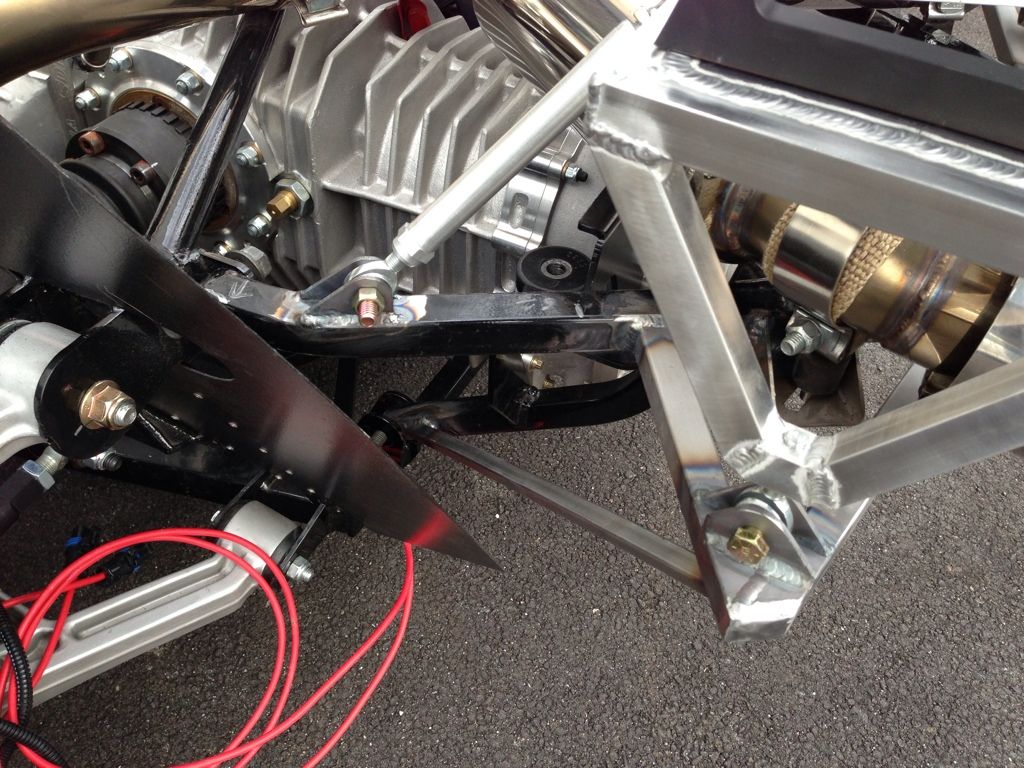

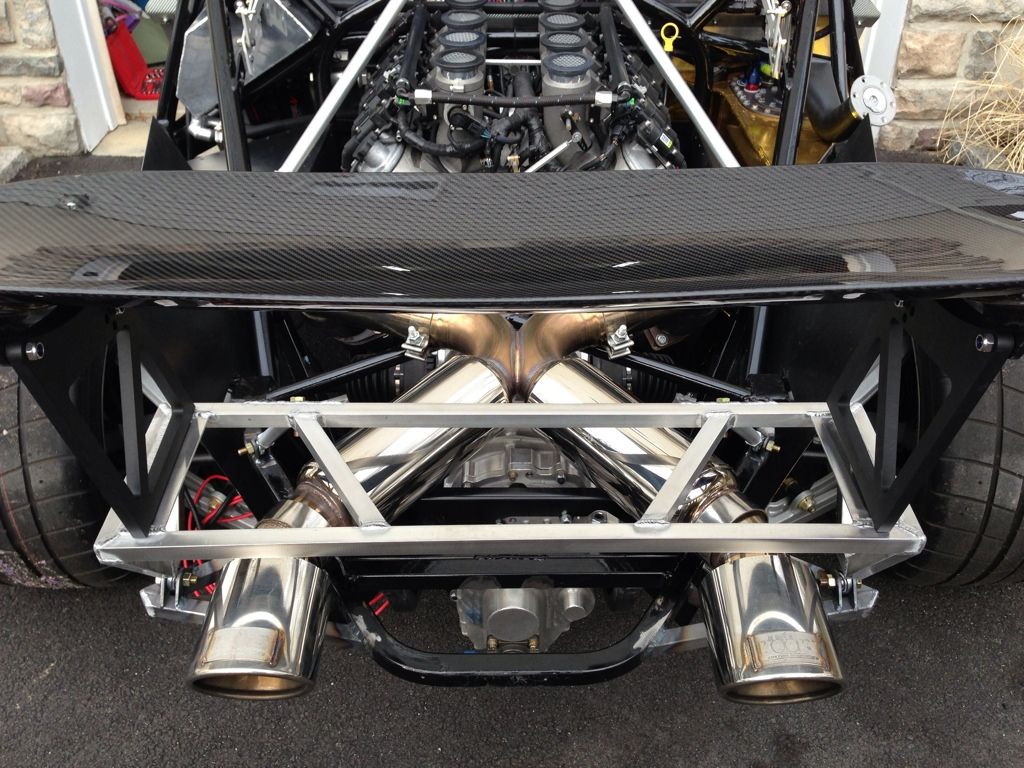

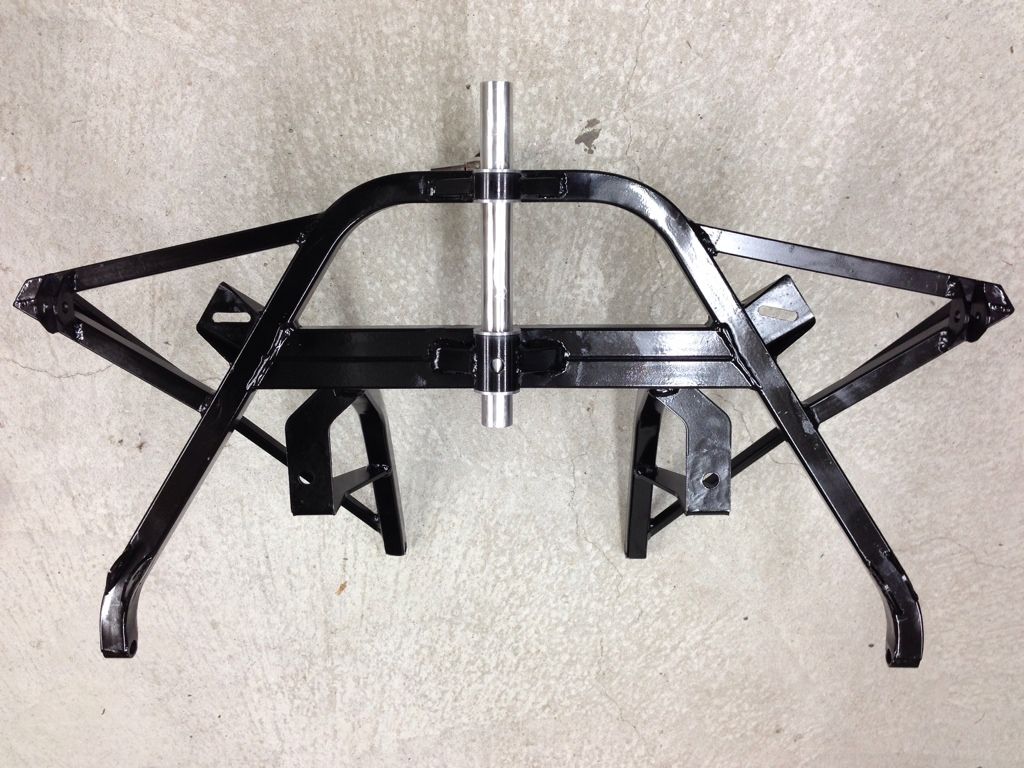

Regarding the cross brace above the transaxle. With the current setup its necessary to remove the transaxle, clutch, and flywheel before the motor comes out easily. I might be able to squeeze it out with the clutch and flywheel still attached, but thatís more of a two man job. I have more in the way of the front accessories with the roll cage additions.

The motor has been in and out 5 times or more and I can do it with help from my 8 year old son who guides and watches the front accessories while I work the lift and twist the motor. The transaxle drops out the rear pretty easily I can do that myself with a cradle I made for my floor jack.

It would be nice to just lift the motor and transaxle out in one piece. I am not at the point where I bring a spare motor and transaxle to the track where a quick motor swap and transaxle swap is a premium. All that said I agree a removable cross brace would be very nice. Its on the list.

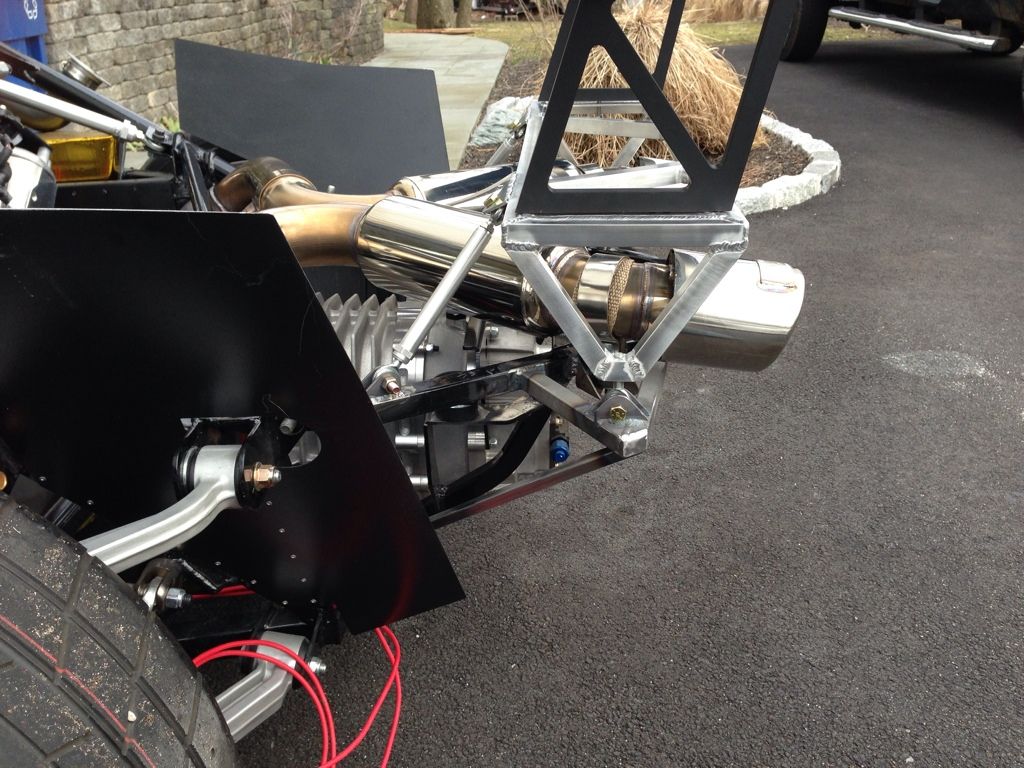

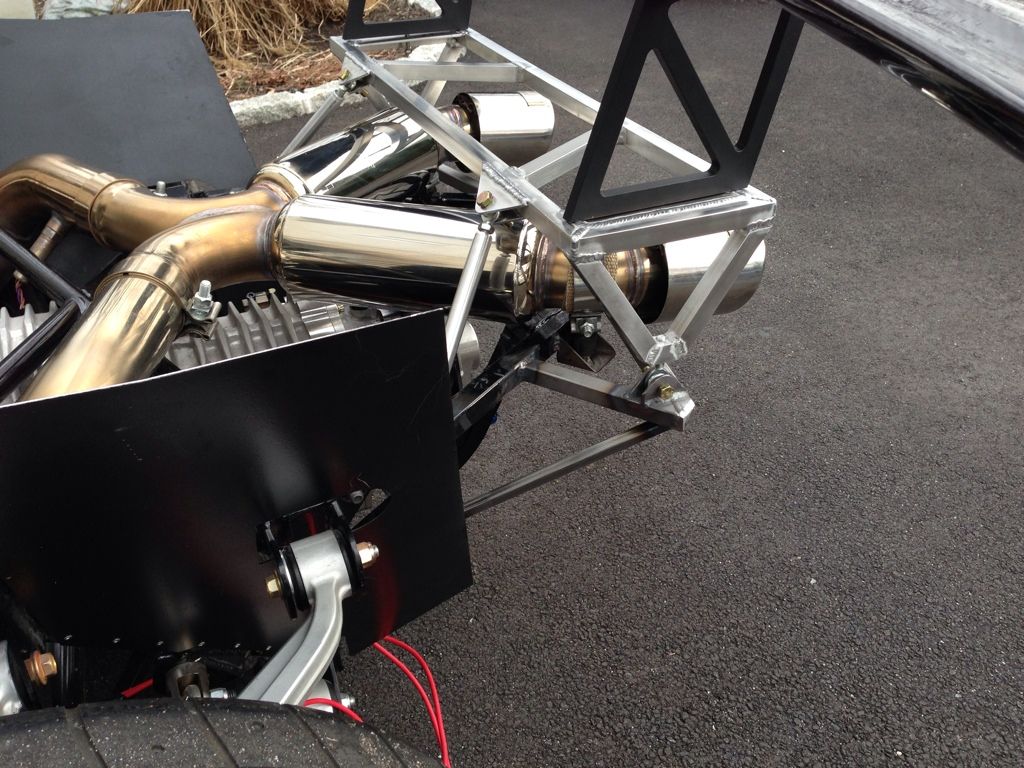

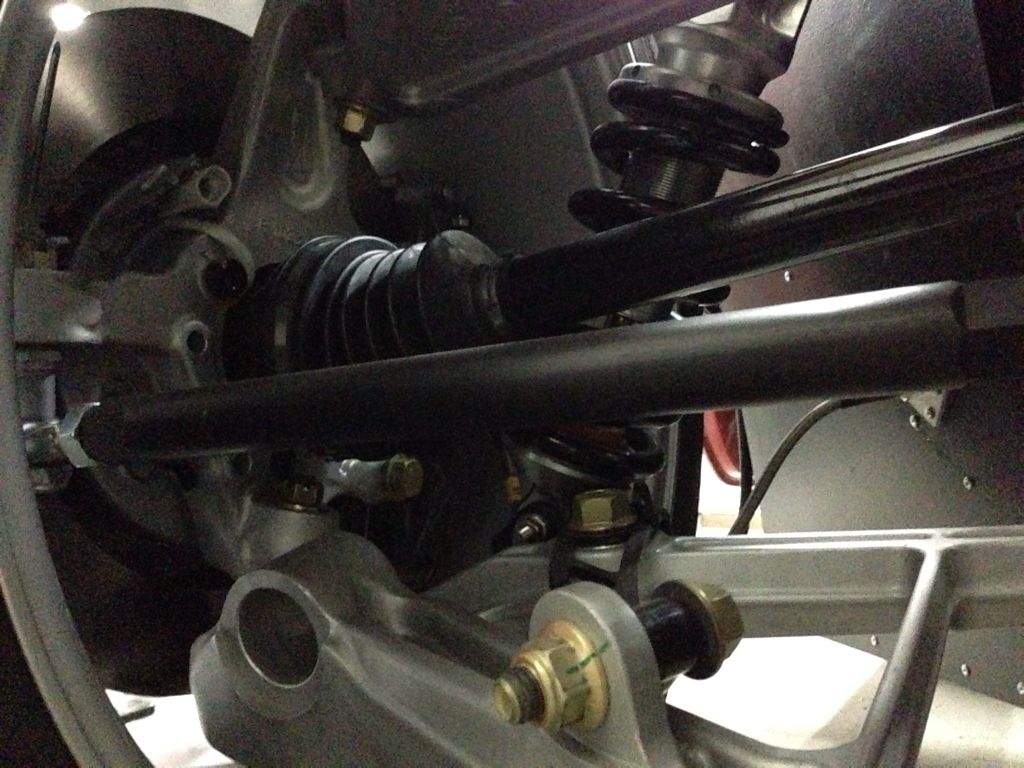

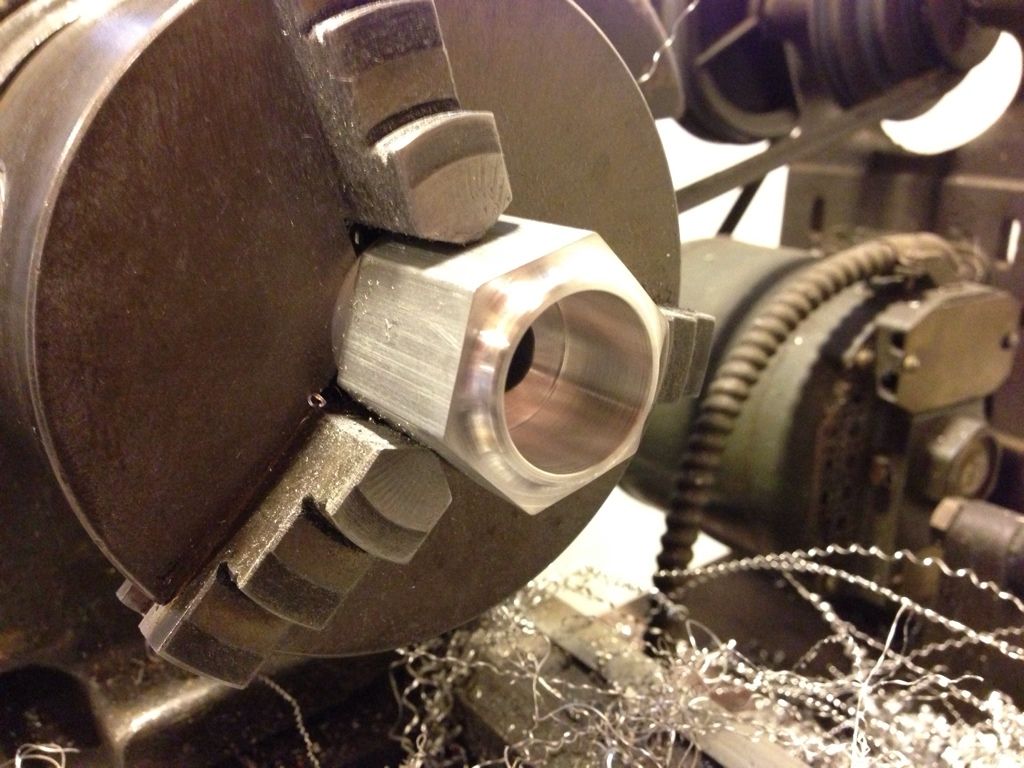

Regarding stiffening the toe links. The stock corvette pieces are good, but could be better. I replaced with aluminum links and rod ends.

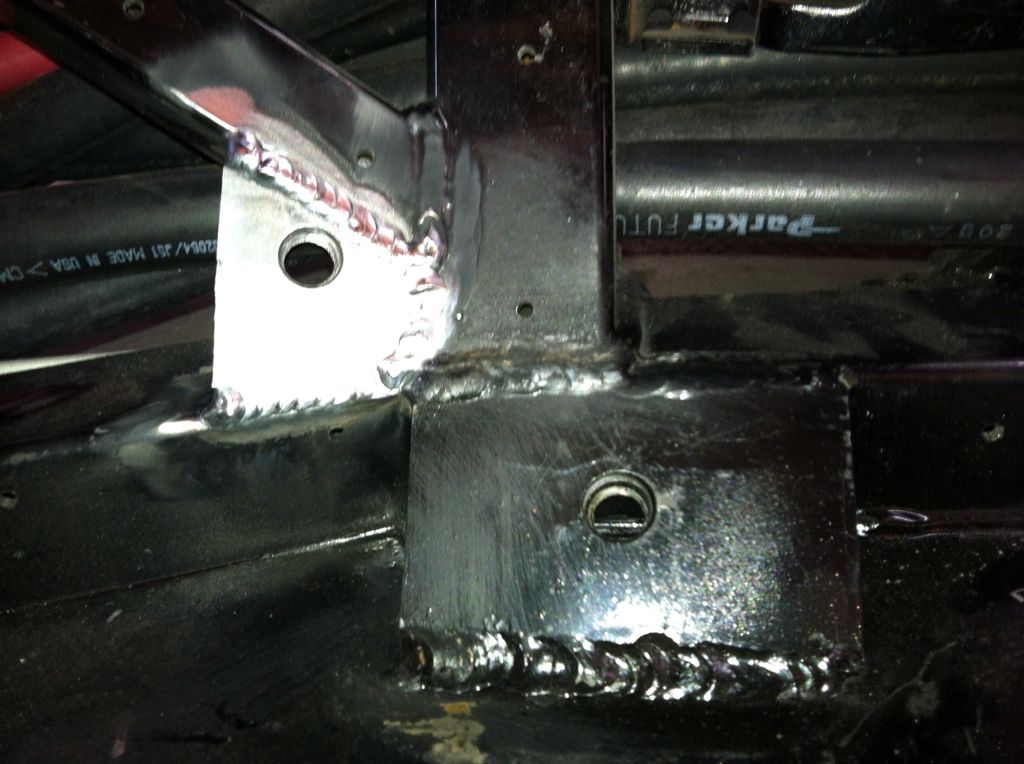

These are both stiffer and the rod ends will take more of a beating and remain tight. Of course that moves the next weakest link to the frame brackets.

Boxing in the suspension mounting points is a project for another time as well. I am interested to see how the stock frame reacts. I am attempting to limit the scope of changes I make these days so I can be sure I am ready to start sorting out the car come March 30th.

You are too kind Hugo. I'm just having fun over here.

John

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

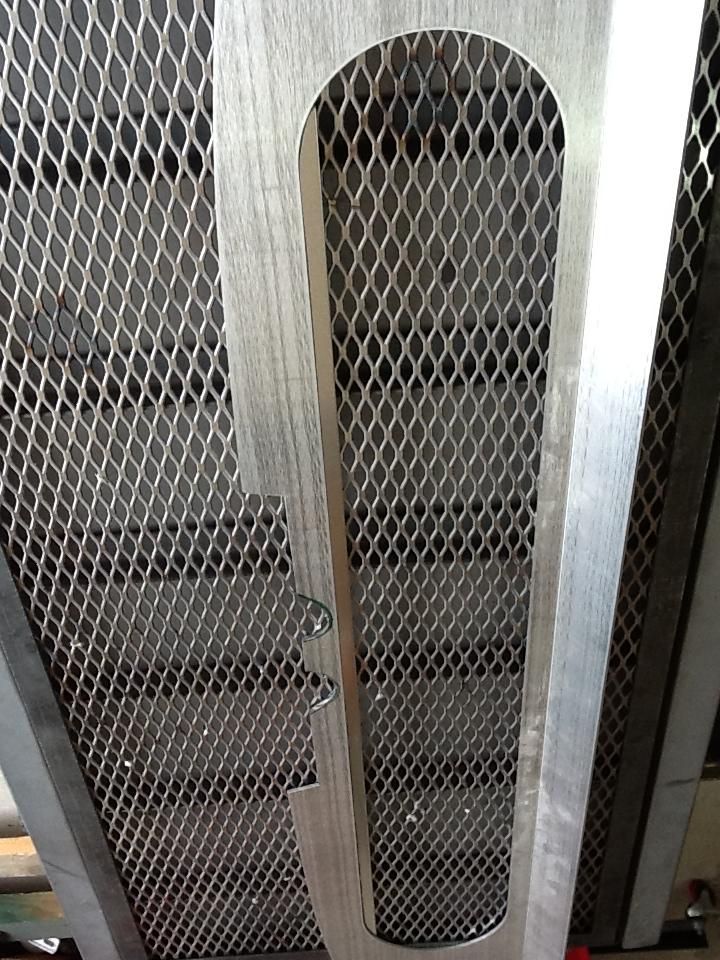

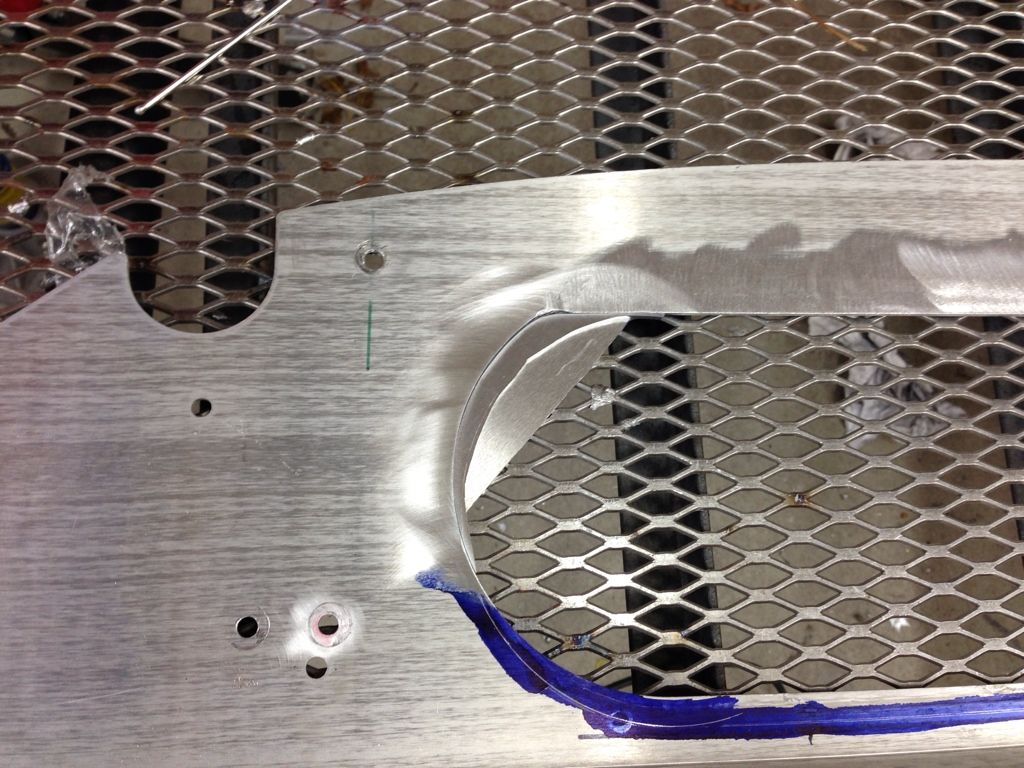

. This is a great design to copy elements from. Thanks for posting.

. This is a great design to copy elements from. Thanks for posting.