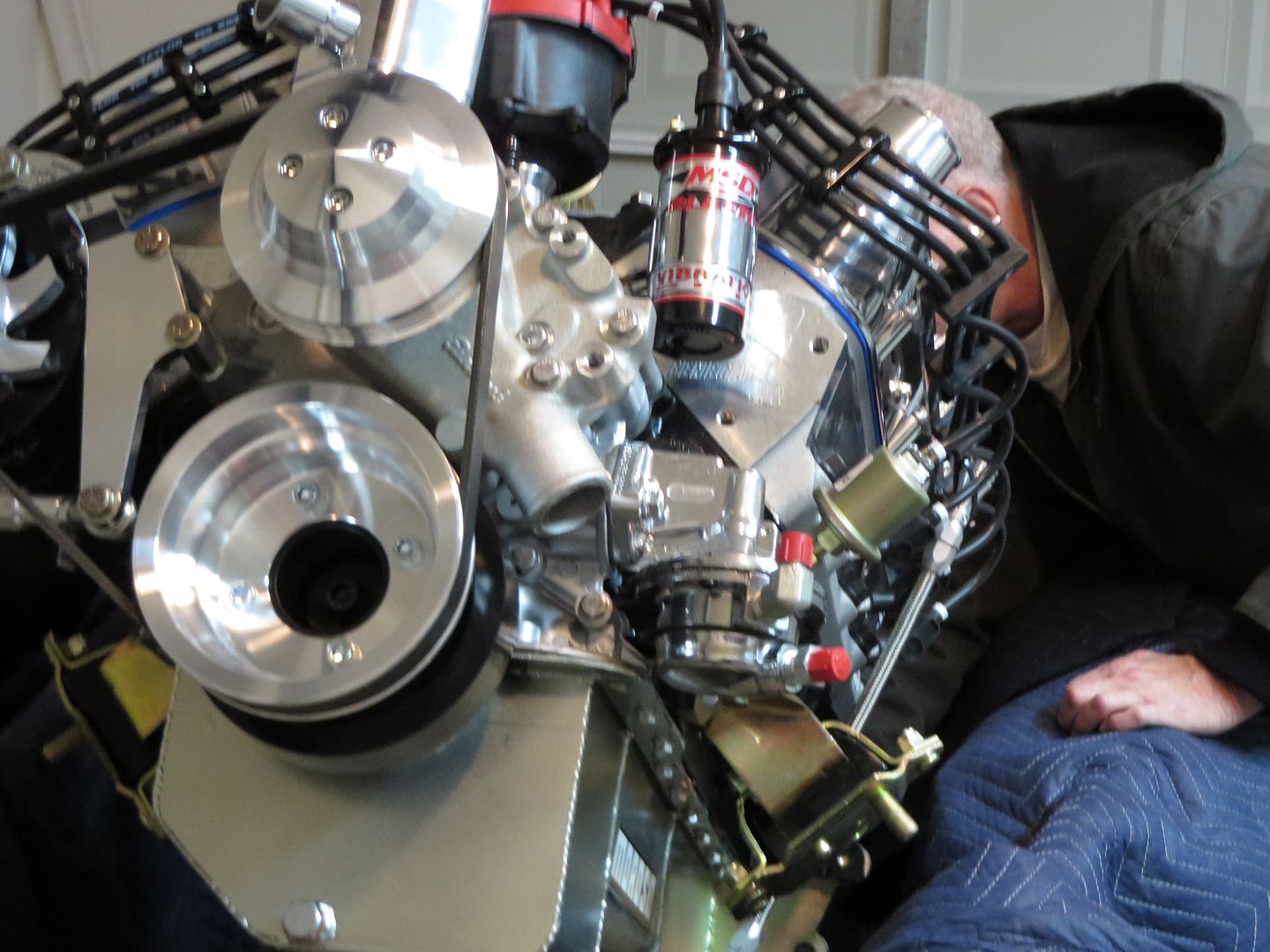

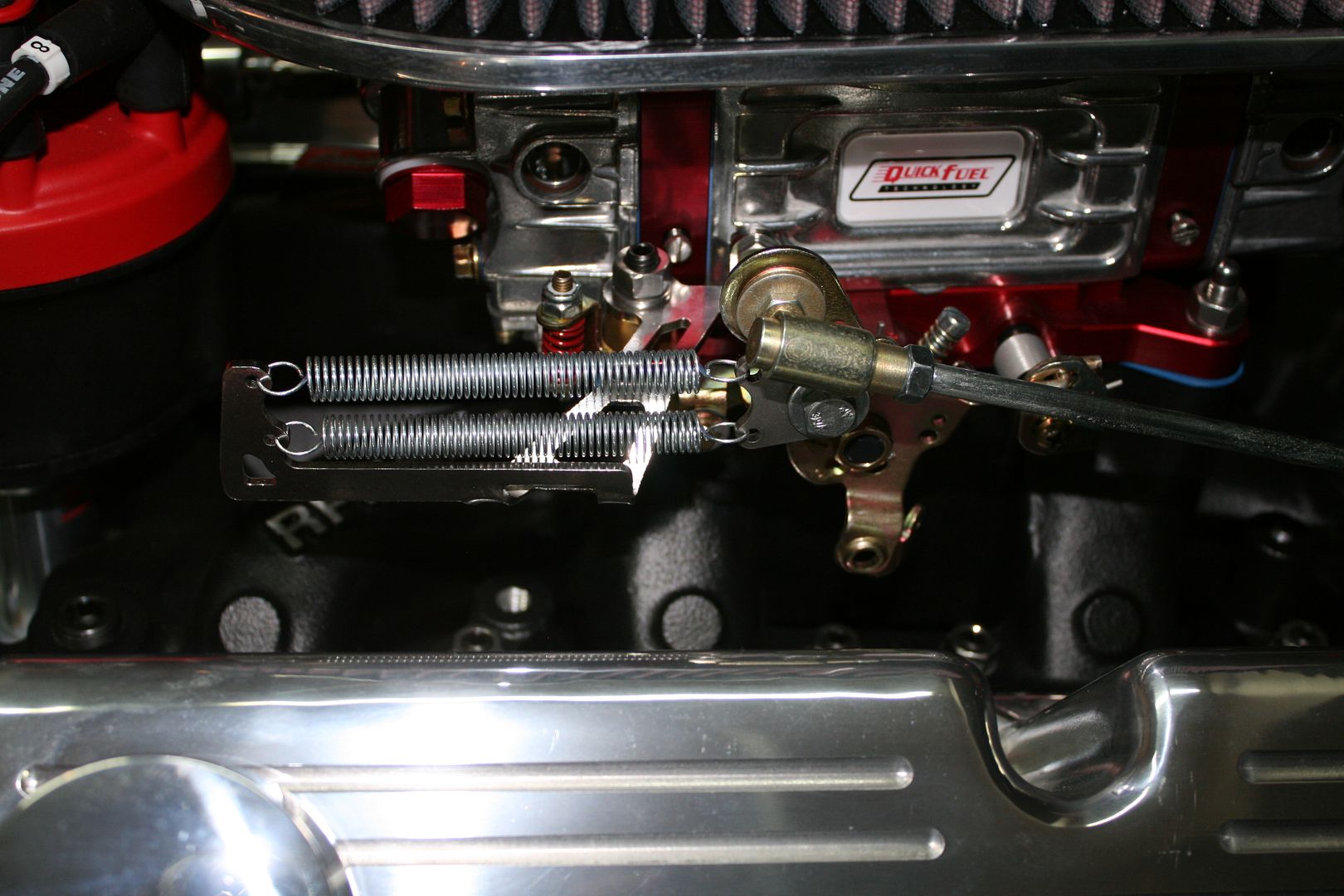

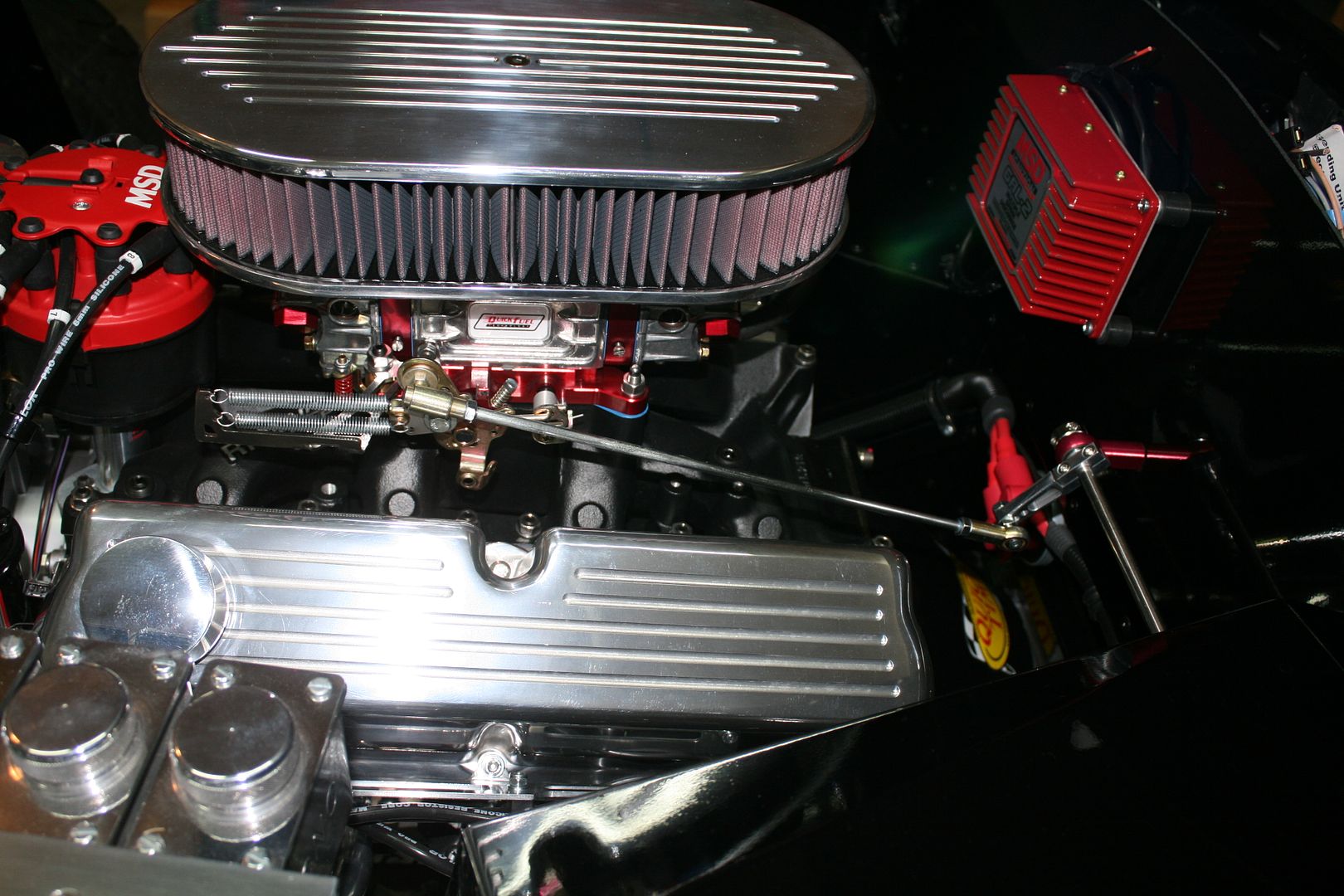

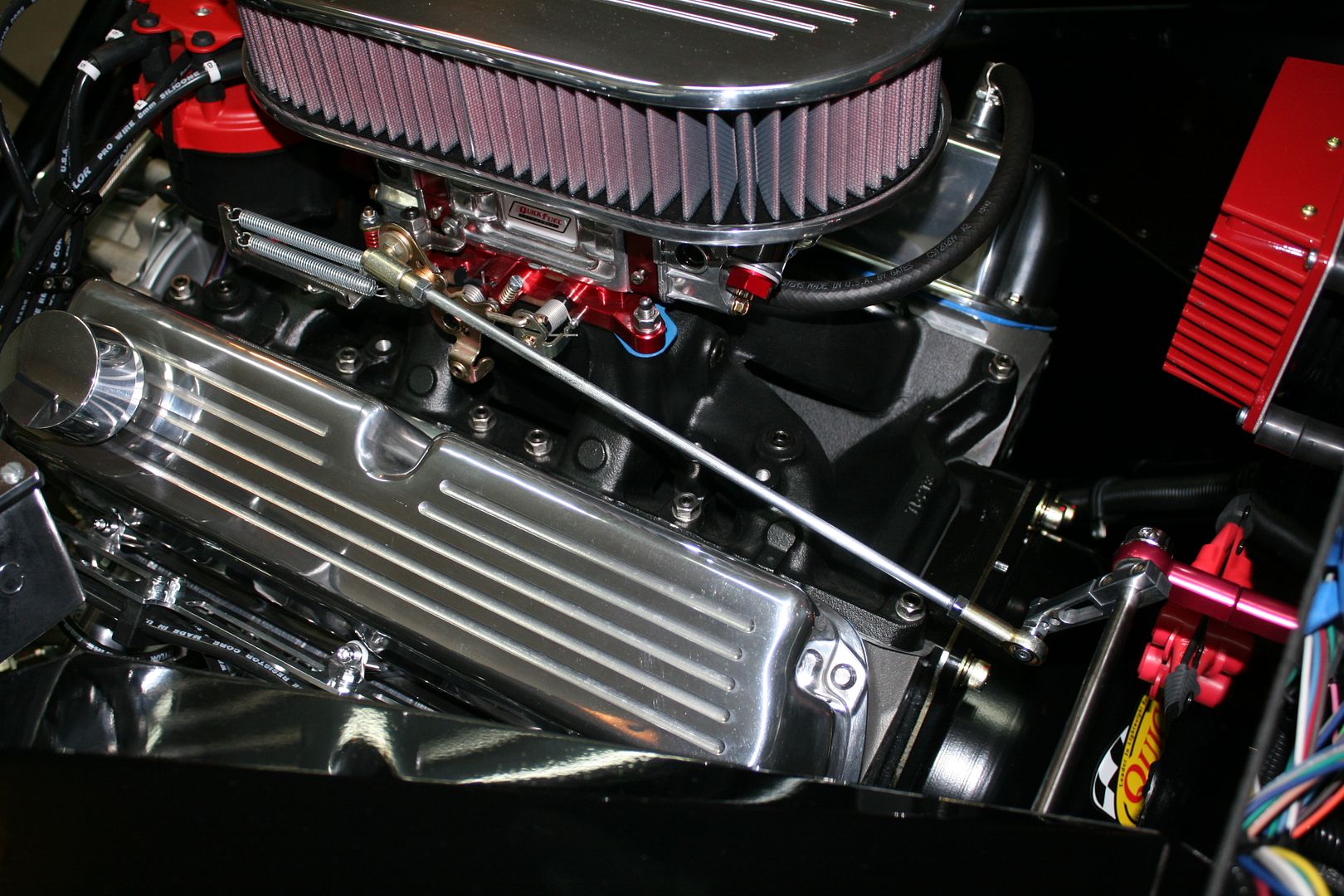

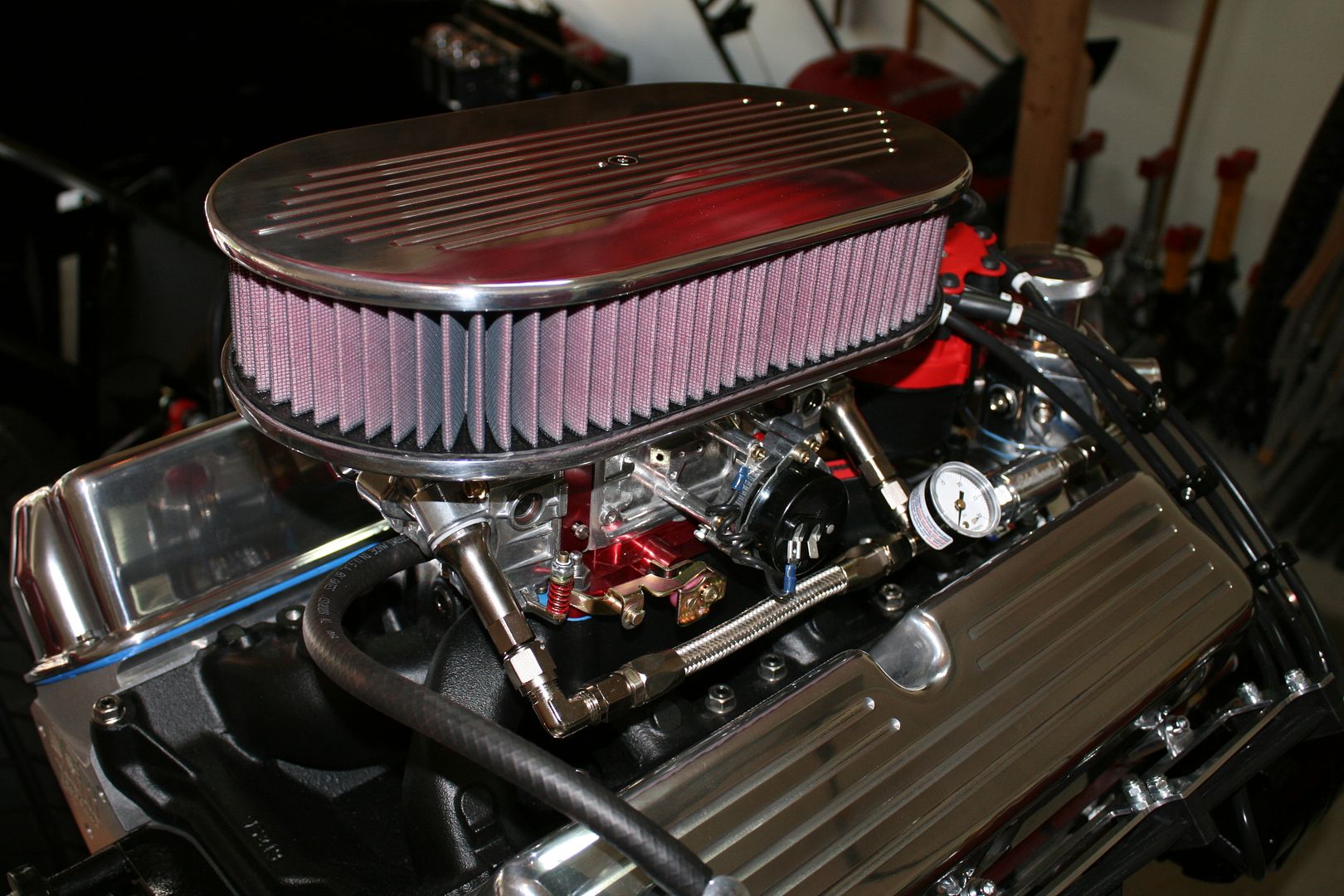

As updates go, this is pretty minor. But still a couple evenings of messing around and I'm happy with the results. I used Billet Specialties for the matching oval air cleaner and valve covers. Nice pieces, but I was concerned the provided 2 inch high air filter element was a little too small (restrictive) plus with the 302 sized block, have available height under the hood for something more. So, found a 3 inch K&N E-9201 that matched the oval dimensions exactly. But when I got it home, the inside dimension of the channels in the air cleaner housing top and bottom were too small. About 1/2 inch all around. The bottom is a cast piece. The top a machined piece. No other K&N options available, and didn't really want to look for something else. So tried to figure out a way to make this one work. Most of my tools are from my former days doing woodworking. I've found that a router with a good sharp carbide bit cuts aluminum pretty well if you have everything anchored down, take light cuts, and go slow. So made a template out of masonite, and with a bushing on the router, trimmed out the top and bottom of the air filter halves to fit the K&N filter. Turned out pretty good. The K&N filter fits like a glove.

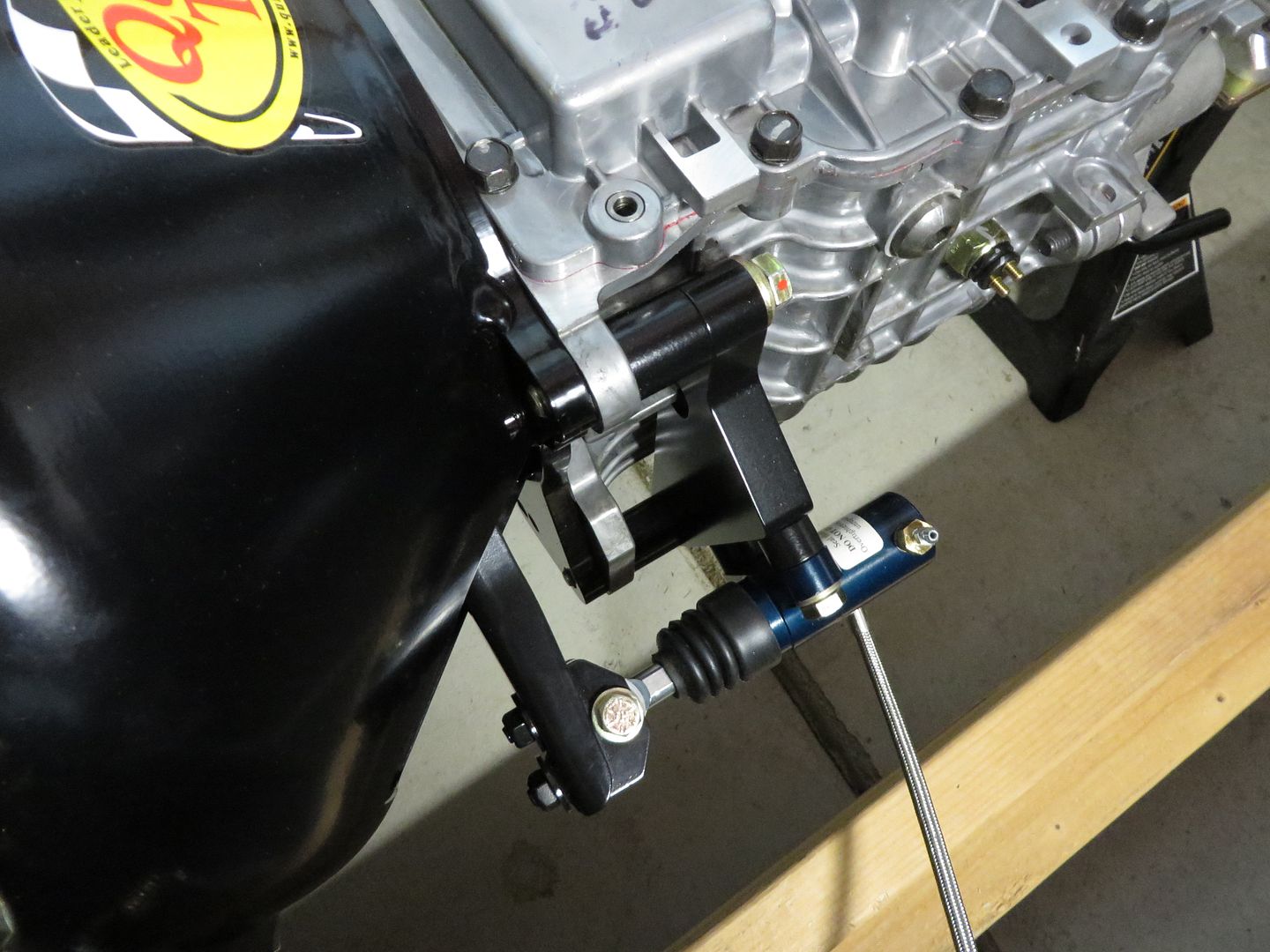

Air filter housing before:

Air filter housing after:

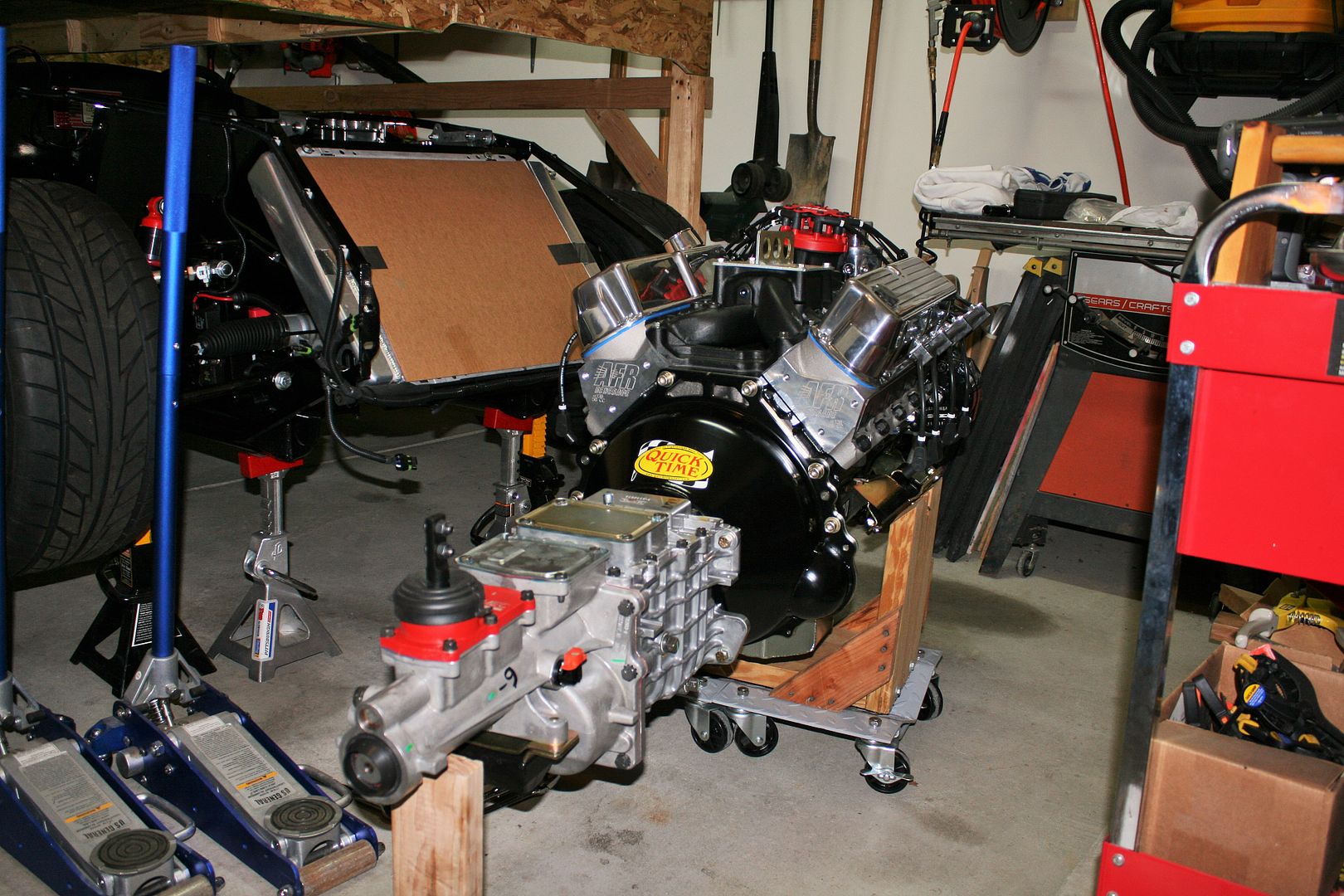

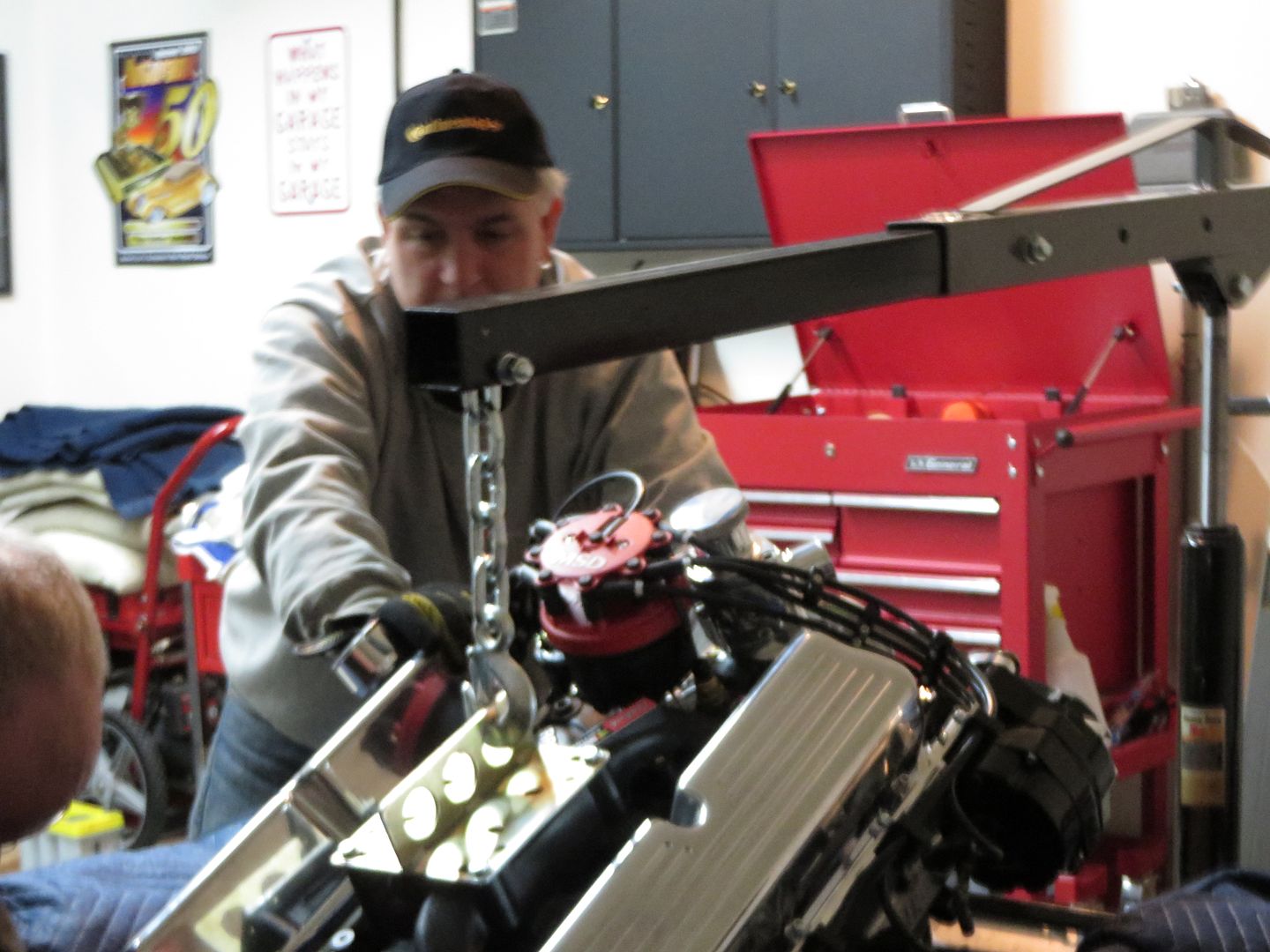

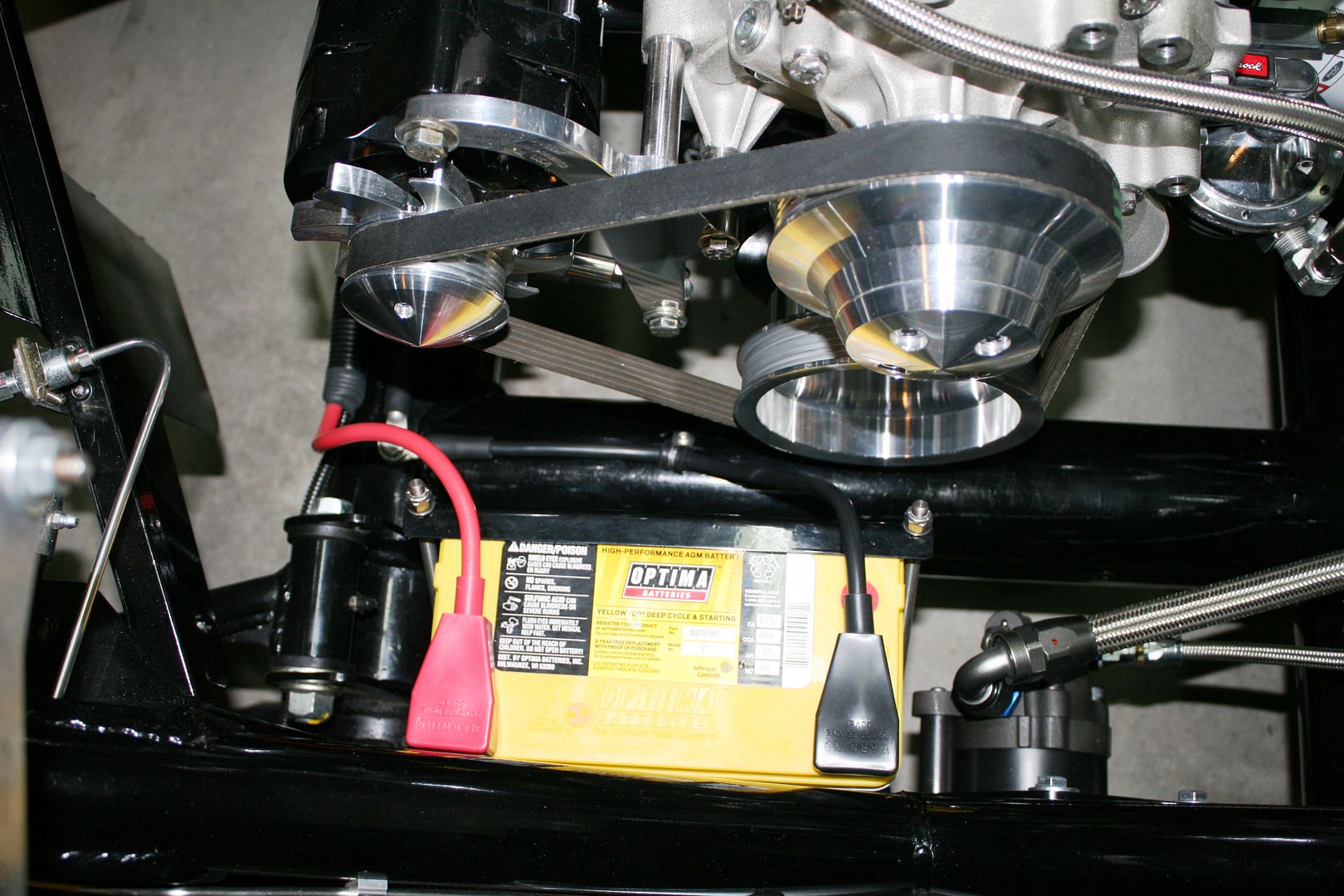

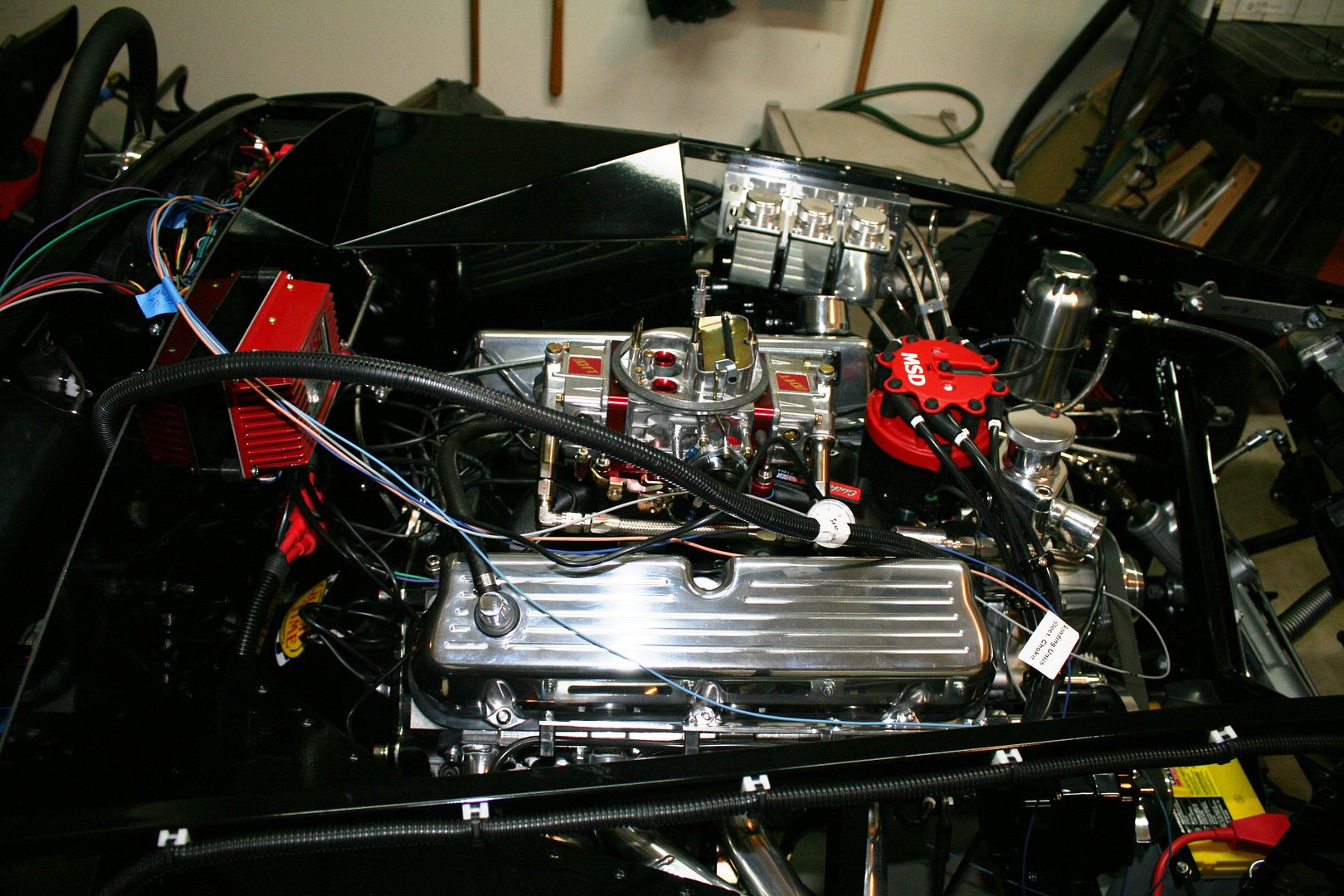

Engine before:

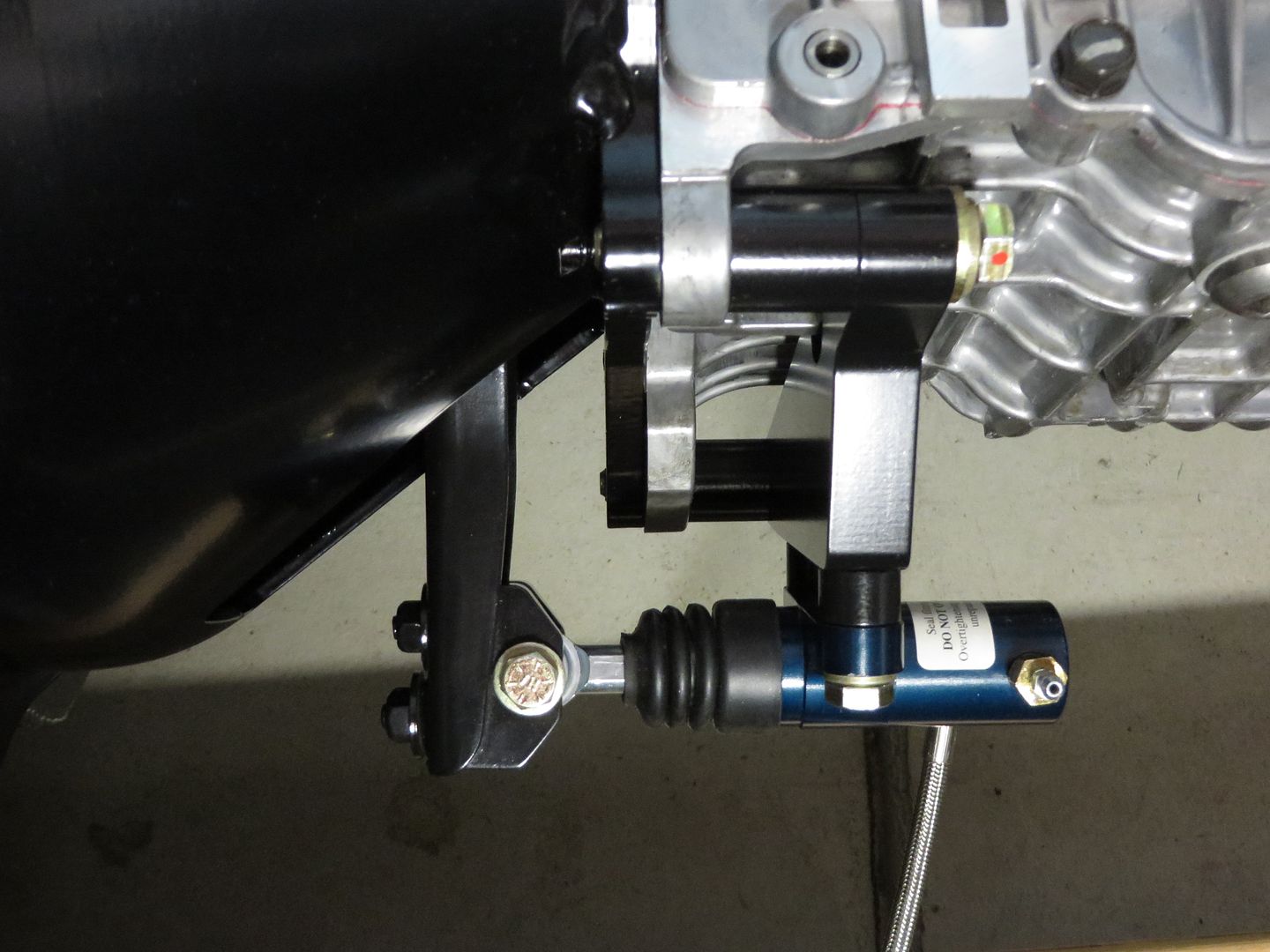

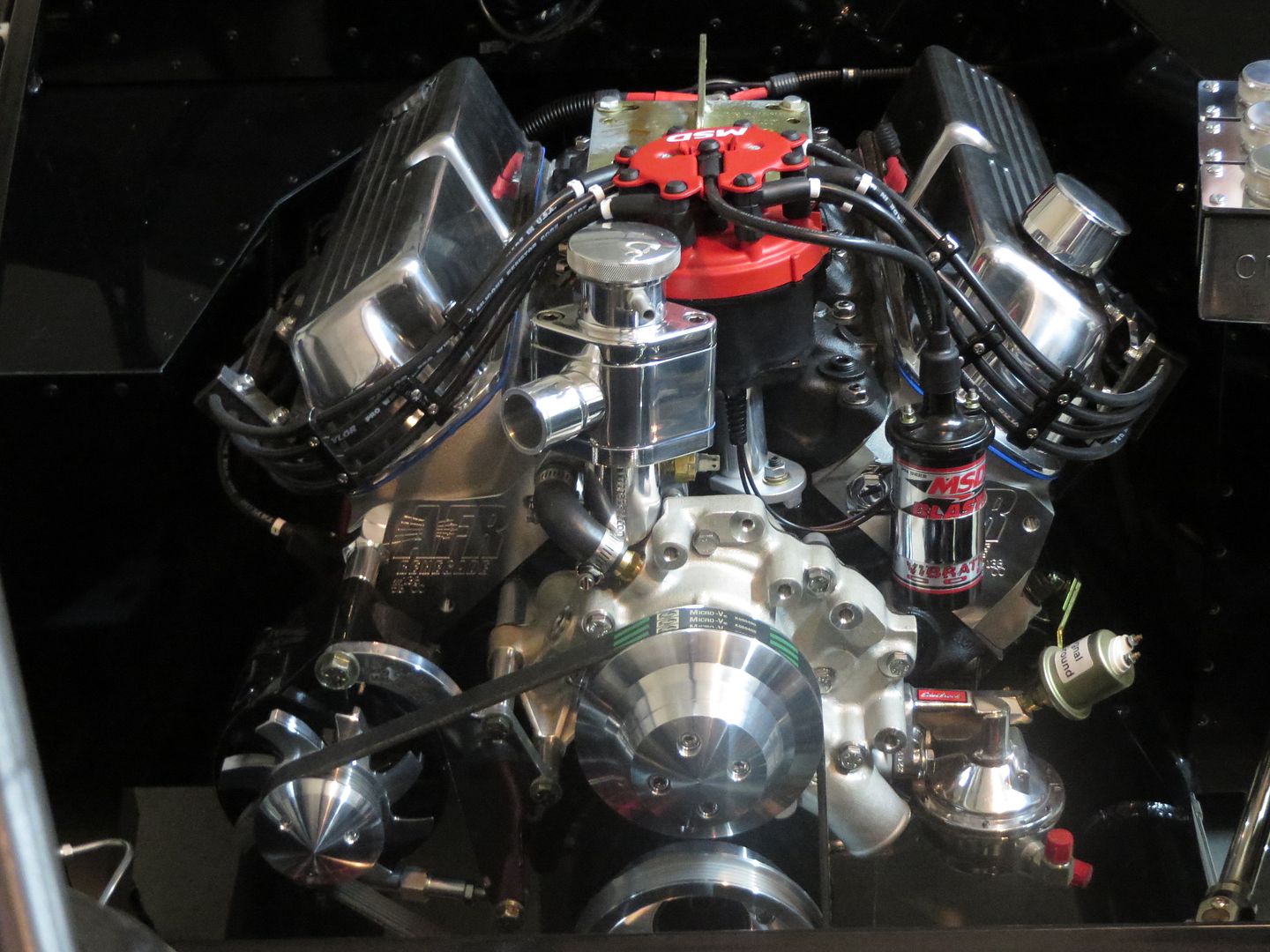

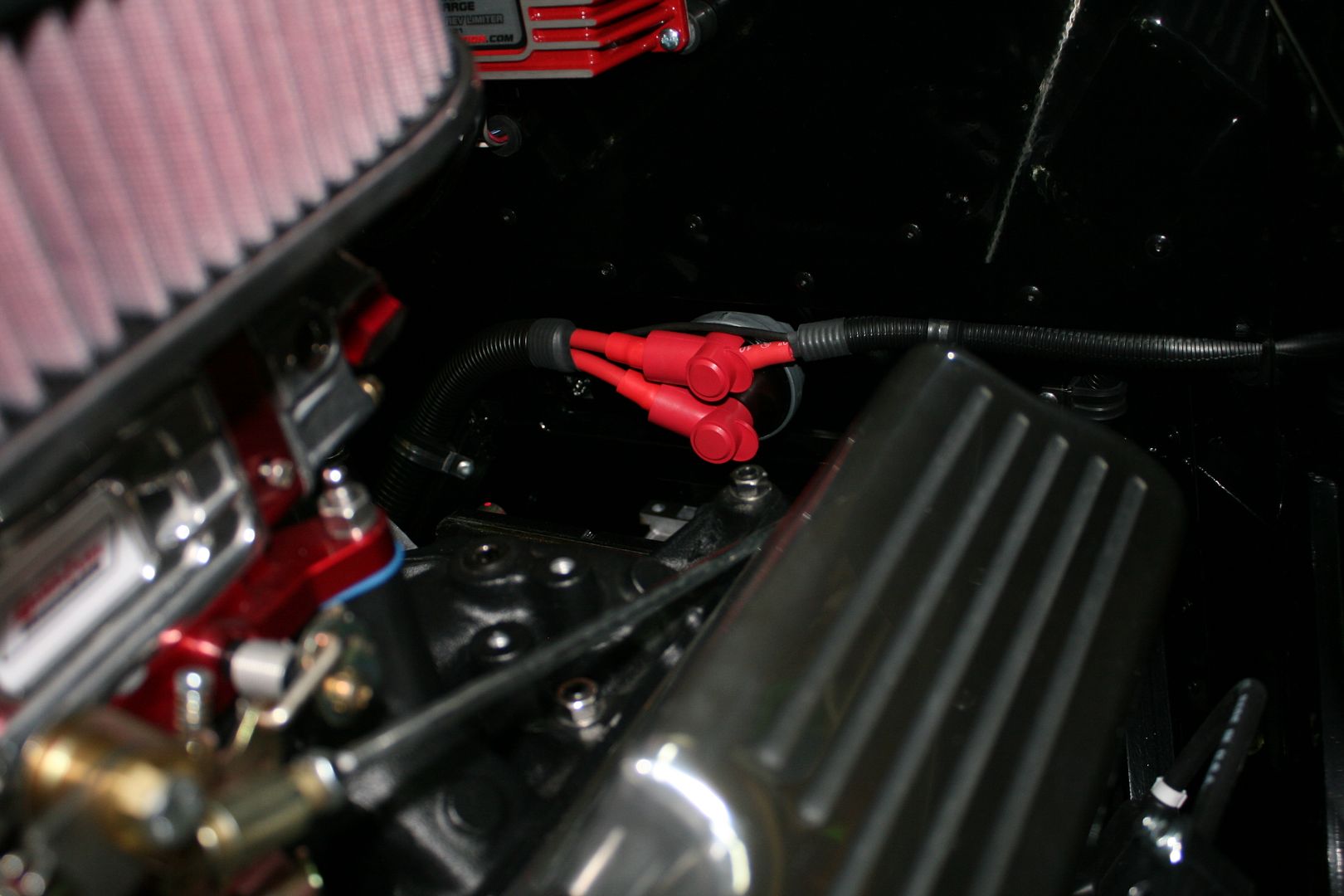

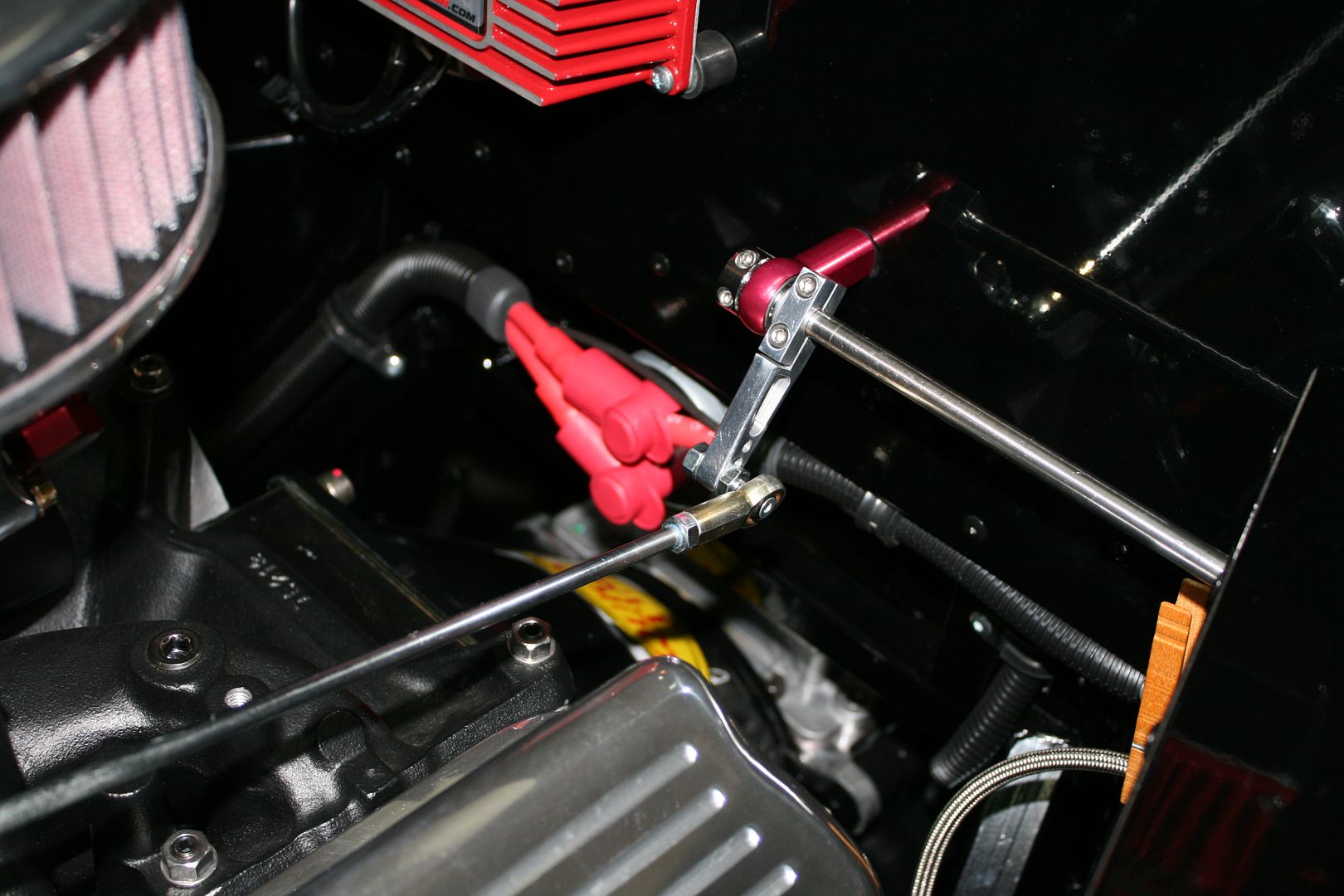

Engine after:

As the pretty lame Wendy's commercials say, "Now that's better!"

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote