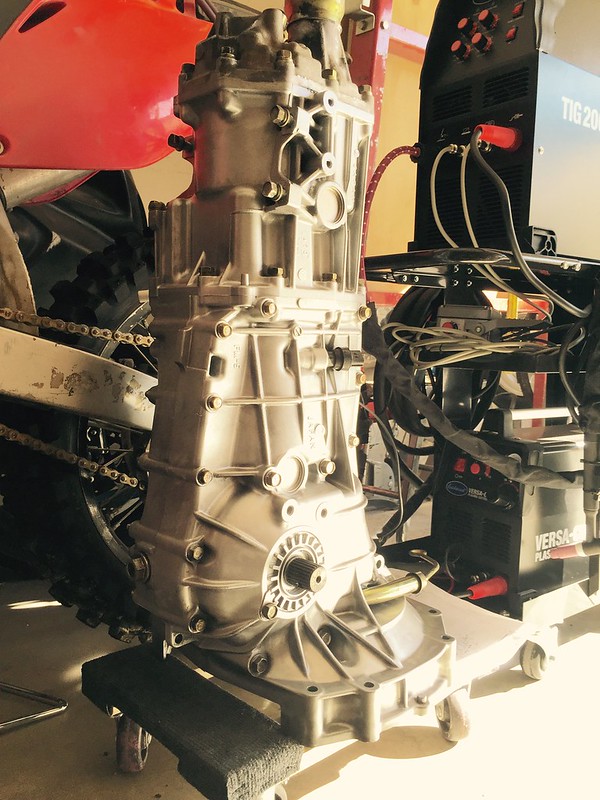

I've been wanting to build an FFR for quite some time, but never really pulled the trigger. I don't know how well I will maintain this thread, but my build finally started when I took delivery of SN #258 12/18/14. The excitement and anxiety are still with me. My daughter and I plan to make this one unique. So far is been lots of unpacking and cleaning the donor parts. I'd like to thank Erik for his inspirational build and letting me see his 818e first hand.

https://www.flickr.com/photos/ninjan...7649964158941/

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

).

).

. K I was just wondering what those were.

. K I was just wondering what those were.