I spoke to Jason two or three days ago, and it sounds like the hatch is coming along well. I can't wait to see the finished product.

I have the car scheduled to have some paint scratches fixed, as soon as I get it back from wiring.

Who knows? It may turn out that I can have the hatch painted at the same time. Then I can get them switched out on the car. While I have the hatch off the car, I'm going to have the hatch hinge pieces powder coated black.

Once the paint is corrected, I'm going to have the final cut and buff done, to bring the paint to a true show finish.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

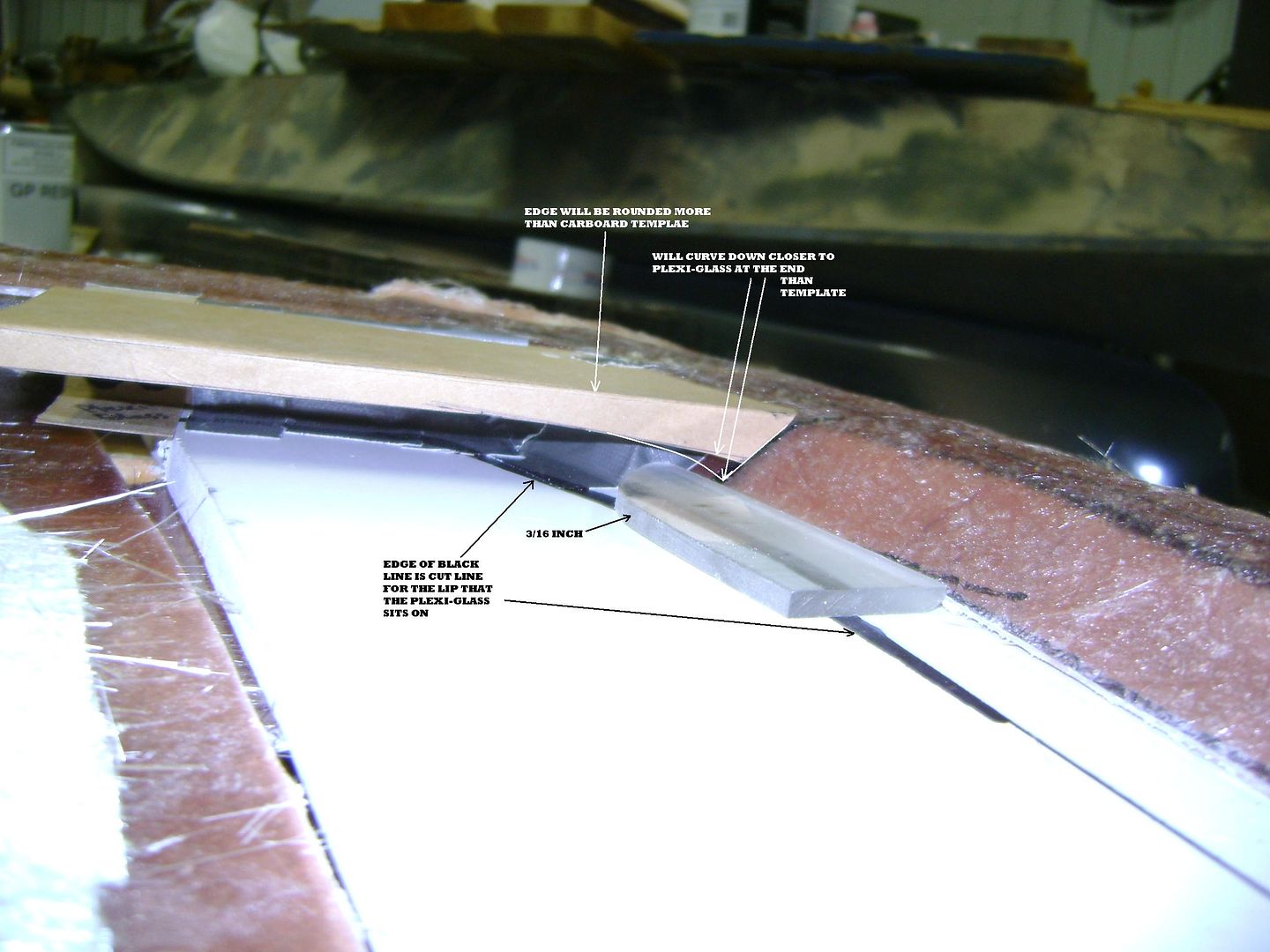

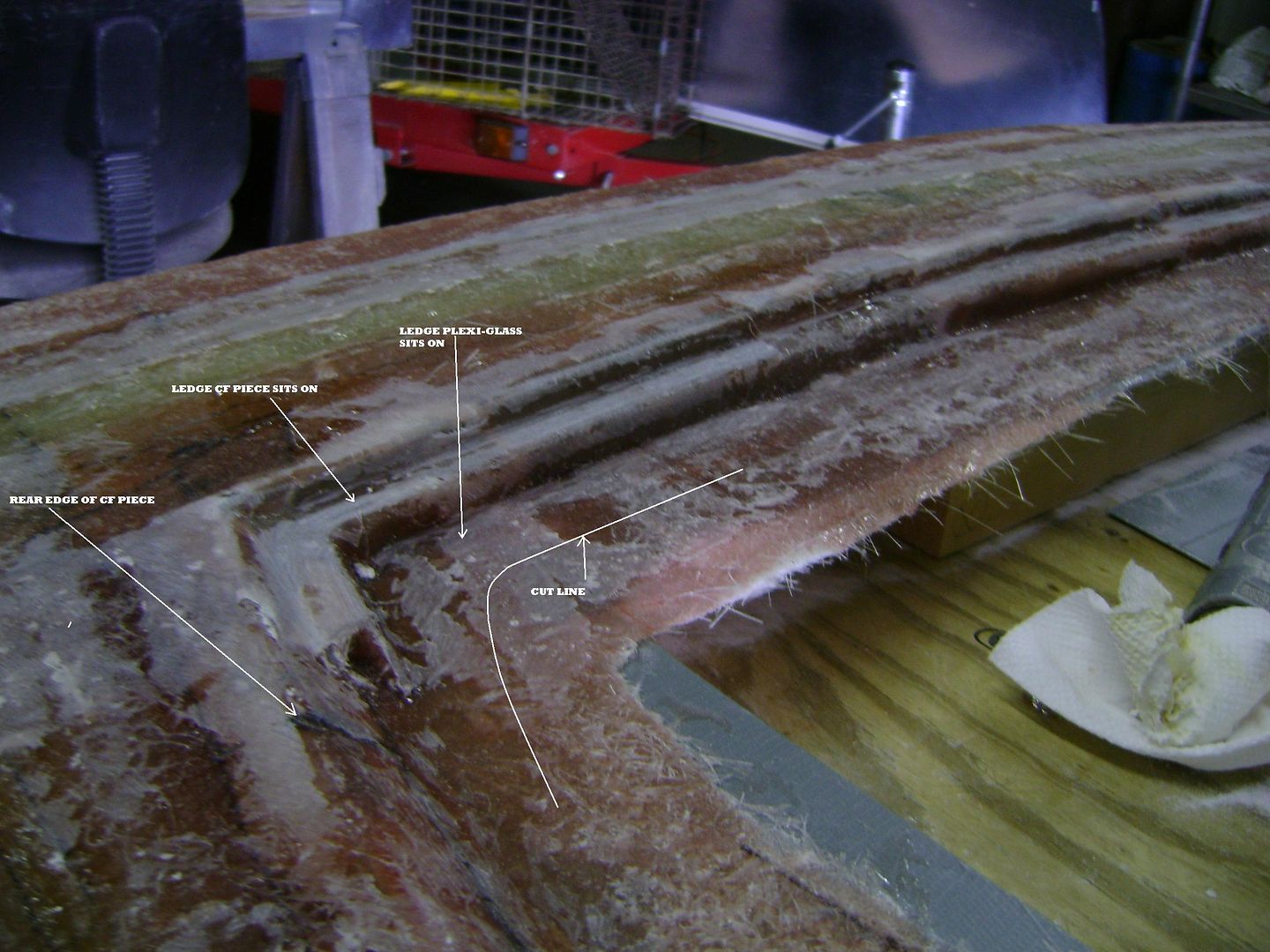

i'm working on the inner section now and i'll have some more pics when i get it in primer. then comes the plug for the carbon fiber "blade" that runs across the top, and making the molds. also have to make a prototype polycarbonate that i'll make patterns off the top and bottom of, to get the exact angles on the sides and back to come out right.

i'm working on the inner section now and i'll have some more pics when i get it in primer. then comes the plug for the carbon fiber "blade" that runs across the top, and making the molds. also have to make a prototype polycarbonate that i'll make patterns off the top and bottom of, to get the exact angles on the sides and back to come out right.