Gosh I dunno.....

porsche-carrera-gt3-rs-06.jpg

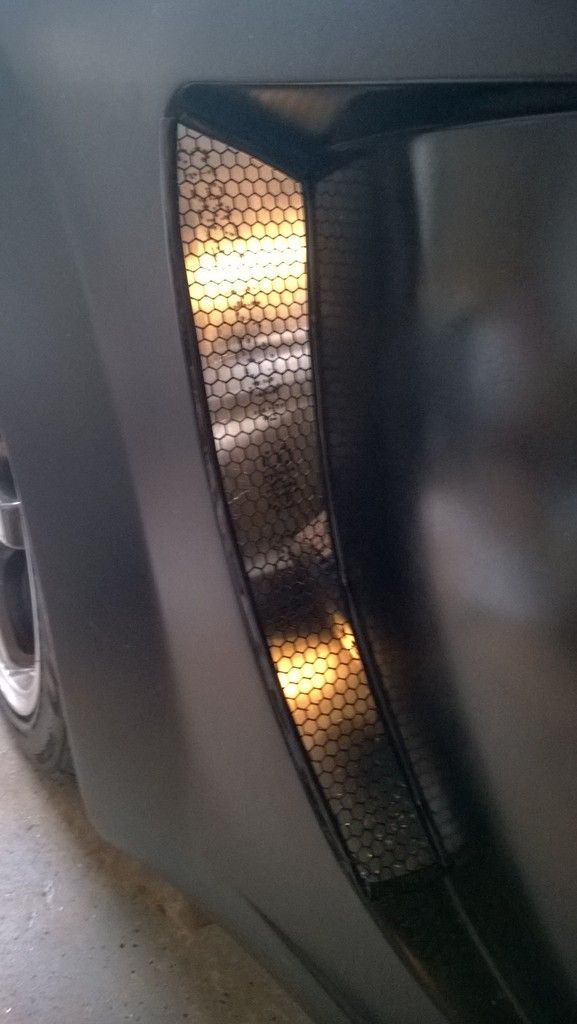

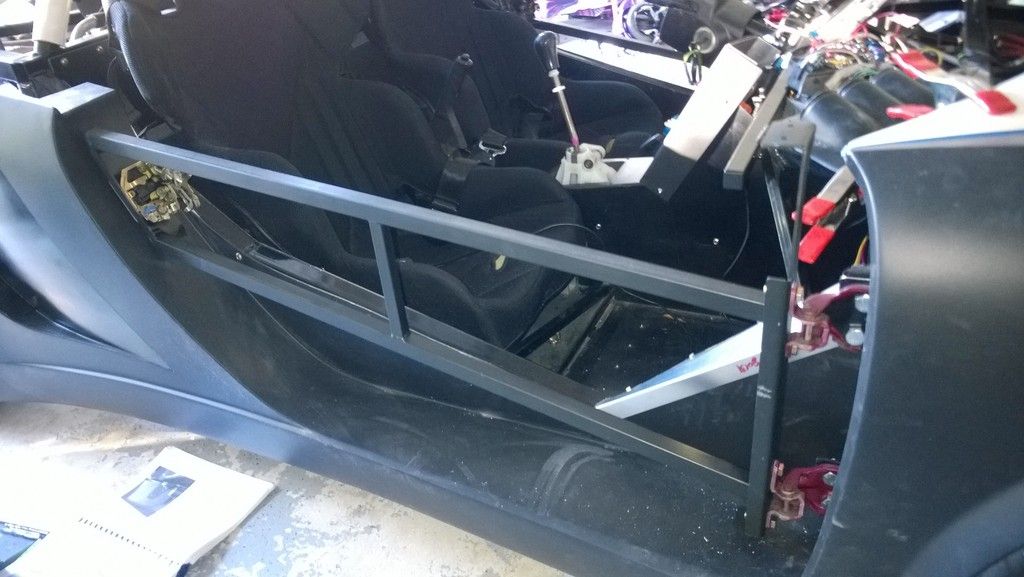

Gloss black accents go with everything, even flat black. Good to have some sheen contrast.

Did you spray the dip with the "DipYourCar" sprayer or did you use conventional equipment with an air compressor? It looks good. Curious as to why you needed to thin the dip.... doesn't it come pre-thinned?

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote