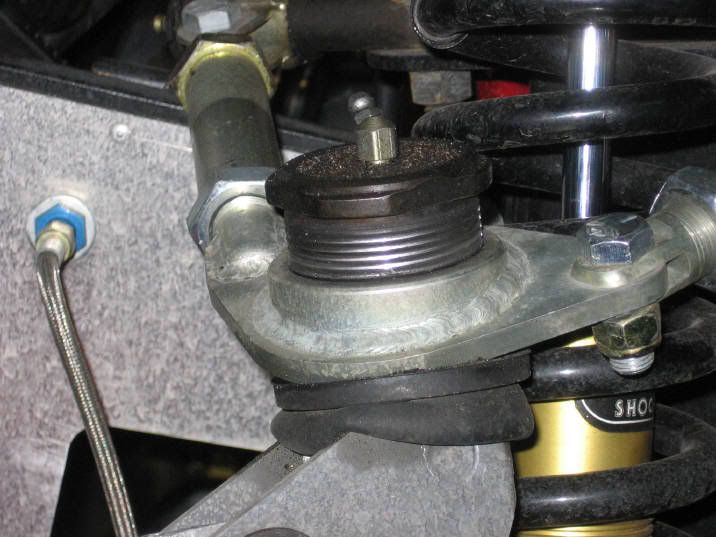

i have the complete kit and going over some of my suspension parts i noticed that the top of the ball-joint is up and not seated into the balljoint mount, the balljoint mount is orientated as the pic shows on page 42 of the mk3 manual, i installed this about 2 years ago and now i am wondering, is the mount reversable, could it be upside down or does it matter?

the otherside it sets onto the mount flush with the square top nut of the balljoint.

what i remember it screws into the mount right?

the square nut top of the balljoint is above the mount for the balljoint about 3/16 of a inch.

going over all my odds and ends to prepare for go-cart.

let me know

Leo

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote