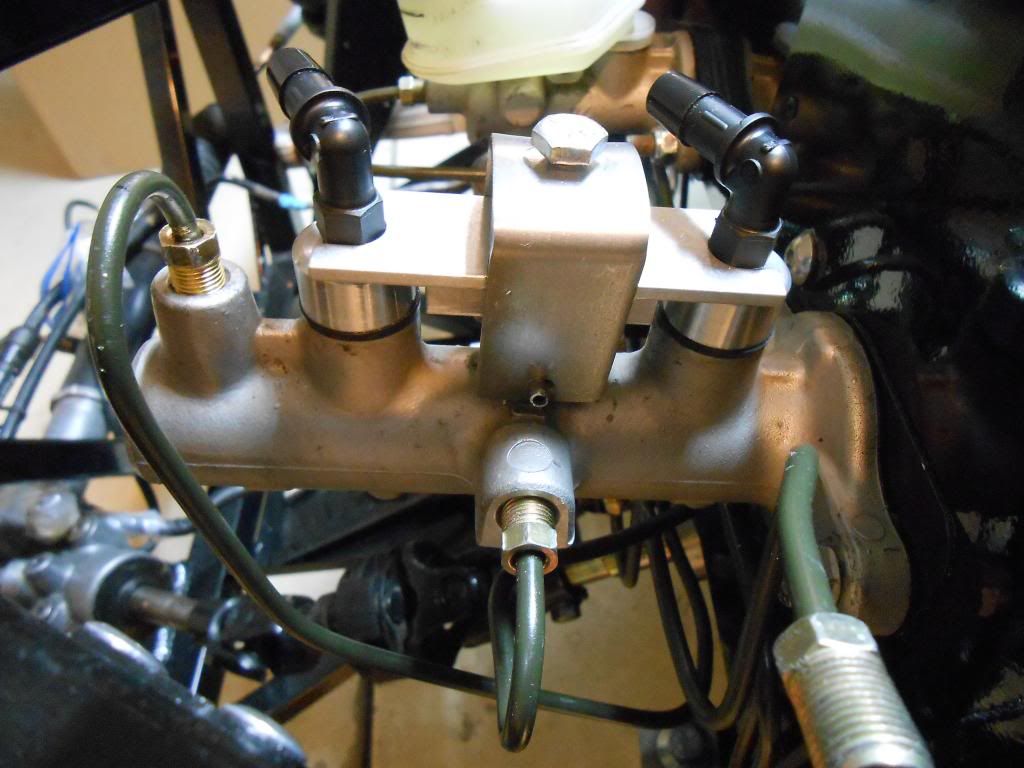

Don't do what I did.

Spent a day doing all the brake lines (abs included) Very neatly.

A total of about 16 fittings. About 10 leaked under pressure. I now have an eastwood flaring tool, but haven't tried it yet.

Bob

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote