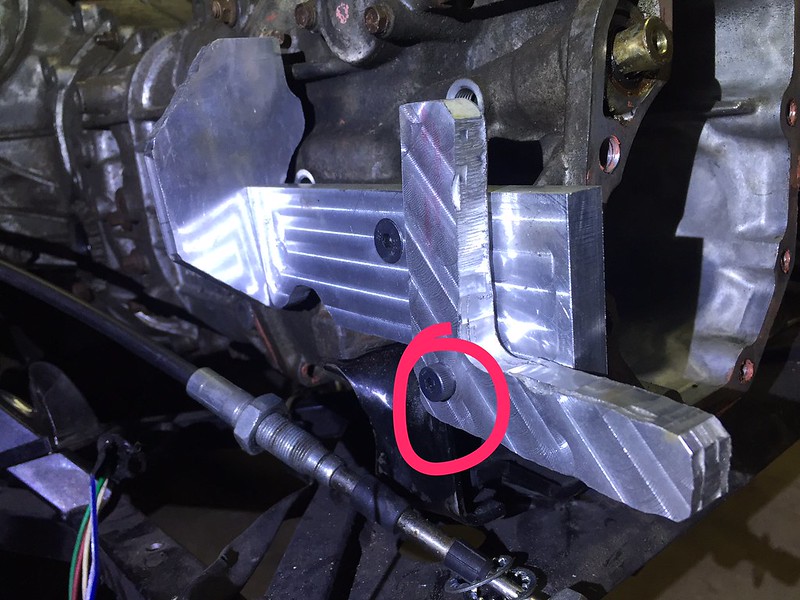

No torque estimates. It was $350 for a new R&P(OEM) and $425 for a heat treated set. I figure that it should make them last quite a bit longer and hopefully be able to withstand the power. Also, less burnouts. A lot less burnouts.

Also-

bearings for just the output shaft were about $250, plus the labor to swap diffs, replace bearings/ring/pinion, reseal everything.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote