oh, i hope not - that sounds like a lot of pressure. haha. could be though. I think they switched to the red panels about 2 or 3 weeks before my production date, so there are certainly a few earlier ones out there, but not sure where they are with the build threads.

I did notice the corners around the trunk lid are pretty rough, but the panels themselves look good for the most part. There are also a few blotchy areas and 1 drip-looking spot in the hood, but I'm thinking once I undercoat the body panels (going to use the 3M rubberized undercoating for this as well) it may minimize some of these imperfections since they were mainly noticeable when there was a little bit of back-lighting. As you can see in the 1 photo above, there is a good bit of shine to the red. Still not to the level of a finished product, but good enough to enjoy the car for a season or 2 before pulling the body back off for paint.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

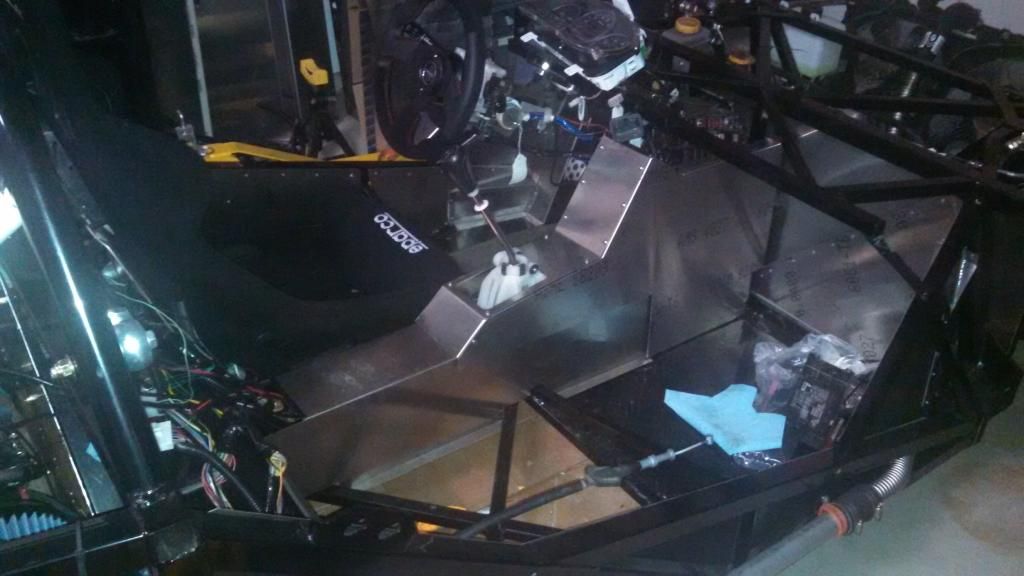

Do yourself a favor and cut a slot in a normal nut with a rotozip to install the throttle cable through the firewall. Also, make sure to drill out the pedal a bit before jamming the plastic retaining bucket/clip through it...or you will break it. Go me for breaking the same part twice in 2 different ways.

Do yourself a favor and cut a slot in a normal nut with a rotozip to install the throttle cable through the firewall. Also, make sure to drill out the pedal a bit before jamming the plastic retaining bucket/clip through it...or you will break it. Go me for breaking the same part twice in 2 different ways.