Howdy Dave!

I have been following this thread with great interest. As part of my own planning and research I was wondering if you were planning on an oil cooler? There was a great article on the Coyote in the March 2010 5.0 Mustang & Super Ford magazine:

http://www.mustang50magazine.com/tec...ine/index.html

About mid article they had the following:

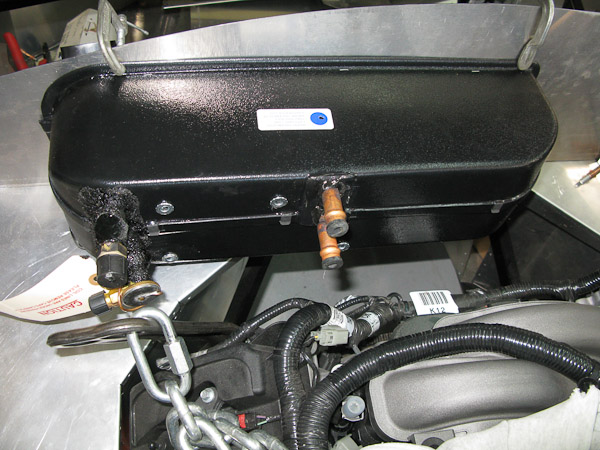

"Consideration was given to an external oil cooler, but ultimately it was decided not to penalize all Coyote buyers for the occasional antics of a miniscule fraction of owners. Oil temperature rises precipitously when the Coyote is revved more than 4,500 rpm for extended periods, and then an external oil-to-air cooler is vital. But those conditions can only be reached on a road-racing track, so the expensive cooler was ditched and engine management strategies were used to protect the engine during hot idles. However, the mounting area for the cooler was "protected" during the 2011 Mustang's development. That makes it easier for the open-trackers among us to fit a cooler (highly recommended by Coyote engine designers), and tells you something about Ford's intentions for special editions of the Coyote-powered Mustangs.

And don't worry about the occasional open-track without an oil cooler. The engineers say the oil cools quickly as soon as you take your foot out of it, and the engine management will limit the torque output if the oil gets too hot."

Would you think it would be necessary for occasional Autocross? I'm not planning on road racing.

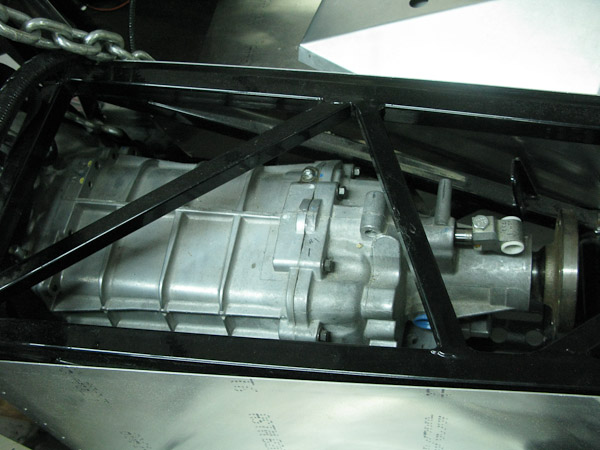

Also - I know you listed a TR-3650 for a tranny, but what rear gears are you planning? 3.55's or 3.27's?

TIA

Chris Lewis

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

)

)