-

01-06-2018, 09:14 PM

#721

I tend to write epic...

Though an outsider to both Subaru drivetrains and Factory Five products, I've used baffled oil pans, Accusumps, and a dry sump, so would like to contribute to this discussion. My one-off (Midlana.com) uses a Honda K24 mounted mid-engine and is turbocharged. Honda K-series engine suffer similar oil starvation in turns but in a different way from Subarus. The Honda I4 engine is mounted with the timing chain on the right side of the car and in long left turns, the oil sloshes to the right and covers the front sprocket and timing chain. The timing chain unfortunately acts like a conveyor belt, lifting oil up out of the pan and flinging it into the cylinder head. A very different engine but with similar results due to hard cornering.

So there's the Accusump. For those who don't know what it is, think of plumbing a rubber balloon into the oil system. When the car starts, oil pressure inflates the balloon until equilibrium is reached. If at any time oil pressure drops, the balloon pushes oil back into the oil system to maintain pressure - that's pretty much it in a nutshell. I had one but got rid of it, and to explain why, well...

The mechanical shutoff valve should be used for mechanical reasons, better flow, reliability, and lower cost. The problem is that you *will* forget to open it before starting the engine, losing the "pre-oiling" feature. That in itself isn't a fault of the product, it's just something you have to remember before heading out on-track. Likewise, when you come in off-track and shut everything off, if you forget - and you will - to close the valve first, 2-3 qts of oil get pushed back into the system when you kill ignition. That's fairly harmless, but it means when you go to start the car, you again don't get the "pre-oiling" feature, and have 2-3 extra qts of oil flaying around until you open the valve and the Accusump charges. Again, it's not really the product's fault but is, again, something you have to remember to do. There's that, and then there's something someone told me that ate at me until I decided it was a real problem. Disclaimer: This is only a theory of mine which may not be completely true, but I've fully bought into it.

The theory is that there are problems with using an Accusump and assuming it's fixed the oil supply problem. The problems are all related to how oil in a traditional oil pan takes on the consistency of chocolate milk when the engine's running hard due to air getting whipped into it, sometimes a lot of air. So you head out on-track and really start leaning on the engine. As you probably know, the crank doesn't actually touch the bearings, it's floating on a layer of oil, and that's great, until it isn't. The problem is that when on-track and at high rpm, oil viscosity drops way off and the high rpm "stirs" a tremendous amount of air into the oil, sometimes as much as 50%. This means that the "wedge" of oil keeping the crank away from the bearings is no longer 100% oil, but is maybe as low as 50% oil. This effectively cuts the viscosity in half again because the air compresses easily in comparison with the oil, and means the crank is riding dangerously close to the bearings. Unfortunately, the oil pressure gauge is no help because 60 psi oil pressure reads the same as 60 psi air pressure. Additionally, the Accusump can't help because the air/oil emulsion is at the same pressure as the oil in the reserve tank, so the Accusump doesn't push any oil back into the system.

Another situation: You're cornering hard when all the above is going on and oil sloshes to one side of the pan, allowing the oil pump to start sucking in larger bubbles. Because they're bubbles, they're followed closely by more oil, so the air gets compressed along with it. In this situation you're right back to the above situation, where you have 60-psi air bubbles in your 60-psi oil, so again, the Accusump doesn't get involved, the oil pressure gauge continues to read normally, but your steady supply of oil to the bearings is now "hiccupping", further worsening the oil situation.

So during the hard corner, the pump finally sucks in enough air that pressure drops off. If this is the first time it's happened, the Accusump works as designed and pushes fresh oil into the system to prop up pressure. But suppose this is the second, fifth, or tenth time it's happened on-track. When pressure is regained after the corner, the oil pump dutifully recharges the Accusump - with an air/oil froth. Have that happen a few times and now the Accusump now contains a 60-psi oil - and air mixture - ready to be pushed back into the system. Is it better than nothing, yes, but just that.

Related to the above, air takes a long time to separate out from the oil. In a dry sump tank, the returning oil is fed into the tank tangentially such that it swirls around the wall of the tank, imposing high G-forces on the mixture. The force de-aerates the oil far faster than it does sitting still inside an oil pan or Accusump. In the case of the Accusump there's another potential problem, that if and when that air separates out from the oil, where does it go? It stays in the Accusump, pressurized to 60-psi just like the oil, ready to be fed back into the engine the next time there's a need. If the Accusump is oriented with the outlet upward, that big air bubble is going to be the first thing into the oil system. If the tank is oriented with the outlet downward, the air remains trapped within the tank. This is a problem that gets worse over time because as the air continues to "off-gas", it forms a bigger and bigger bubble at the top of the tank. After a while, the "2-3" quart Accusump actually contains maybe 1.5 quart of oil and 1.5 qts of air.

In addition to all the above, there's one more thing which may or may not be a problem, which happens coming out of a turn that required the Accusump to "dump its load" into the engine. In that situation, the OEM oil pump is having to supply full oil pressure to not only the engine, but also the partially-empty Accusump reservoir. Does the OEM pump have the capacity to send oil to both at the same time? Who knows.

I'm afraid that in the case of the oil system, you really do get what you pay for. The harder you plan to run the engine and the more G forces it's going to see, the more a dry sump becomes less optional. As said above, this is a working theory of mine that I've "decided" is true without doing any testing with an Accusump. If someone using an Accusump to fix a known oiling problem finds no bearing issues during a rebuild, well, maybe I've decided too much.

Last edited by kb58; 01-12-2018 at 08:08 PM.

-

03-19-2018, 05:12 PM

#722

818r center seat

FFR 818r Instagram biknman69

2020 Ram 2500HD, 19 Forester Touring DD, 96 GM coupe for SCCA SM

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

• Ernest Hemingway

-

05-16-2018, 12:52 AM

#723

My STI is rebuilt and racing again, The Blue Sake Bomber lives!

I installed a Vacuum gauge to see how much vacuum the DS pump is pulling. This is an Aviaid 2 stage DS pump, 5.5" Jones Racing serp pulley, Fluidamper crank pulley, Cosworth DS Pan, Peterson Vacuum Regulator. These pics are only under no load with no turbo boost blow by, so they aren't representative of what I'll see at the track, but I'm still very pleased with these numbers.

Cold Idle right after startup, 13.5":

Cold, 1,500 RPM, still 13"

Warm, 3,500RPM, 13"- Excellent!

Warm, 500-700 RPM Idle. The Vacuum drops to 1-2":

And an engine shot as it stands today:

I'll video the Vac gauge this weekend while racing so we can see the vac under full blow by race conditions.

Last edited by Sgt.Gator; 05-16-2018 at 12:57 AM.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

05-16-2018, 06:00 AM

#724

Tazio Nuvolari wannabe

Nice looking setup. I like how you have cool air directed onto the filter. What HP is it making? It looks like a smallish turbo in the stock location.

I'm doing reversed NA intake on my '07 with GTX3576R, larger T04S frame with 4" inlet and 2.5" outlet, Tial 1.03 A/R housing with V-bands. Would be hard to do that DS setup the way I'm configuring it. Guess I could move the PS pump and put small alternator there.

More pics or descriptions of the car? What class do you run?

-

05-16-2018, 12:46 PM

#725

Originally Posted by

Scargo

Nice looking setup. I like how you have cool air directed onto the filter. What HP is it making? It looks like a smallish turbo in the stock location.

I'm doing reversed NA intake on my '07 with GTX3576R, larger T04S frame with 4" inlet and 2.5" outlet, Tial 1.03 A/R housing with V-bands. Would be hard to do that DS setup the way I'm configuring it. Guess I could move the PS pump and put small alternator there.

More pics or descriptions of the car? What class do you run?

It's hard to do a reversed intake and do the DS pump on top; I don't think I've seen that done <yet!>

My car is the blue #28, this pic is at the ICSCC race in Spokane last summer:

The cool air duct is obviously a cut up stock inlet. What you can't see is that above and slightly behind the filter I have a small hood vent with a lip to pull air across the filter and out the engine bay. I'll post a pic below.

I originally intended to race this car in the Thunderhill 25 Hour enduro. So I modded it with NASA ST3 / Thunderhill 25 E0 class as the goal and with lots of enduro mods like transmission cooler, power steering cooler, diff cooler ready to go (if needed, so far it's been ok temps), EWG turbo built into the turbo housing (No EWG pipe off the uppipe to crack a weld after 23 hours of non stop racing), Brake Fans, Coolant lines to the Tial EWG. Reality has set in and I realize I will never be a team owner taking this car to the 25 Hour. I'm working on other options to participate in some capacity there.

I run 3 classes all in the ICSCC: ST (10lbs/hp); SPM (unlimited HP); and ME0 (Enduro class, unlimited HP). The turbo is small, the intent being to have lots of power under the curve. In ST3 type HP/Wt classes the goal is to hit MAX HP/TQ for your weight as soon as possible and hold a straight line across the RPM band at that level. Quick spooling smallish turbos work well for that. A high HP peak at high RPM is counterproductive. I have an ATP 3067 EWG turbo.

These are last year's tunes with ported heads. This year with the rebuild I have oem heads which dropped the peak power about 10-20 HP/TQ. Which proves why ported heads are minimally cost effective until you get way up there in power goals.

2017 Ported Heads: 295 HP / 289 TQ; 344 HP/ 357 TQ; and 355 HP/388 TQ.

2018 OEM Heads: 277 HP/ 286 TQ; 323 HP/ 330 TQ; and 345 HP/ 375 TQ.

If I quit doing ST HP/Wt racing I'd probably get an ATP 3076 EWG, It should be almost a straight swap. That would put me in the 400s easily.

There's two threads on this car thru 3 owners on NASIOC:

The original build: https://forums.nasioc.com/forums/sho....php?t=2035408

My ownership: https://forums.nasioc.com/forums/sho....php?t=2836784

Back to Dry Sumps and Oiling issues...

Last edited by Sgt.Gator; 05-16-2018 at 12:49 PM.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-06-2018, 09:27 PM

#726

Has anyone had a leak at the oil pickup area on the Aviaid pan? I can't tell if it's leaking at the bolts or the base of the fitting that meets the pan. I've inspected the o-ring and that looks good. Everything is nice an snug.

-

06-07-2018, 03:49 PM

#727

-

06-07-2018, 08:11 PM

#728

Originally Posted by

RetroRacing

Yes, bolts.

Thanks! Fixed with RTV?

-

06-07-2018, 08:54 PM

#729

Moonlight Performance

Originally Posted by

Sgt.Gator

2017 Ported Heads: 295 HP / 289 TQ; 344 HP/ 357 TQ; and 355 HP/388 TQ.

2018 OEM Heads: 277 HP/ 286 TQ; 323 HP/ 330 TQ; and 345 HP/ 375 TQ.

Thanks for sharing that - very good info. Who ported the heads? What cams? Same cams in both dyno tests?

-

06-08-2018, 01:01 AM

#730

Senior Member

Originally Posted by

Aero STI

Has anyone had a leak at the oil pickup area on the Aviaid pan? I can't tell if it's leaking at the bolts or the base of the fitting that meets the pan. I've inspected the o-ring and that looks good. Everything is nice an snug.

I have a very small amount of oil seeping out between the pan and fitting. Not enough to leave a drip on the ground. See yellow circle in attached picture.

also, I put studs in all pans parameter holes.

Bob

drip.jpg

Last edited by Bob_n_Cincy; 06-08-2018 at 09:57 AM.

-

06-08-2018, 01:26 AM

#731

Originally Posted by

Hindsight

Thanks for sharing that - very good info. Who ported the heads? What cams? Same cams in both dyno tests?

BuiltEJ Stage 2.5 heads. STI OEm cams both tests, same tuner, same dyno.

The heads aren't listed on the website, but we came up with them after I called him. Easy to work with. I wanted more than Stage 2, but we both agreed that the +1mm valves were not needed that come with Stage 3, hence the stage 2.5.

And I changed my mind on the next turbo, it will be a Gen 2 ATP 3576 EWG.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-08-2018, 11:21 AM

#732

Moonlight Performance

Cool thanks for the info.

As for the ATP turbos - Is the one that you mention a stock-location turbo? Because I recall they had a stock location 7163 and it performed terribly compared to the main (rotated) version, according to all the dyno charts I saw.

-

06-08-2018, 01:51 PM

#733

Originally Posted by

Hindsight

Cool thanks for the info.

As for the ATP turbos - Is the one that you mention a stock-location turbo? Because I recall they had a stock location 7163 and it performed terribly compared to the main (rotated) version, according to all the dyno charts I saw.

Stock location. Plug and play almost. I can basically pull my 3067 out and plug a 3576 in.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

09-24-2018, 08:57 AM

#734

Senior Member

Oil filling crankcase when 818 not used for more than a couple months.

My 818 has an Aviaid dry sump system. It has 2 external scavenge pumps and uses the OEM oil pump.

drysump.jpg

Twice while the car sat without starting the engine for 3+ months, the oil from the tank filled the crankcase. This last time, I believe it was high enough in the block to get past the piston rings and fill the exhaust manifold. When starting, the car smoked badly for 5 to 10 minutes.

Has anyone else seen this with a dry sump system on a flat engine?

Bob

Last edited by Bob_n_Cincy; 09-24-2018 at 09:21 AM.

-

09-24-2018, 11:27 AM

#735

I don't have experience with drain back on a boxer engine but can see it happening. Bob what I have done on engines I have had with a DS system is remove the belt and spin the pump over with a small electric motor. In my case it was to prime the engine before starting. For the 2 stage scavage system like the Element kit it would work evacuate the crankcase, I don't know if you could get enough oil in a cylinder to hydra lock the engine but something to consider. I would think the height of the oil tank will have an effect on the drain back as well.

-

09-24-2018, 12:25 PM

#736

Originally Posted by

Bob_n_Cincy

My 818 has an Aviaid dry sump system. It has 2 external scavenge pumps and uses the OEM oil pump.

drysump.jpg

Twice while the car sat without starting the engine for 3+ months, the oil from the tank filled the crankcase. This last time, I believe it was high enough in the block to get past the piston rings and fill the exhaust manifold. When starting, the car smoked badly for 5 to 10 minutes.

Has anyone else seen this with a dry sump system on a flat engine?

Bob

I was just about to post a similar issue. I did a first start two months ago, then let it sit, it's been seeping oil on the floor from what I think is the cam seals. The sump tank is very low now, but I bet the cylinders are filled with oil, too. I think this is just an inherent problem with dry sump systems. After talking with some other people, it seems dry sumps will eventually do this the only option is to put a shut off valve in the feed line (I don't know if I like this idea) or to drain the oil if you know it will be sitting for a bit (Apparently, a lot of race teams do this).

-

09-24-2018, 12:57 PM

#737

Tazio Nuvolari wannabe

I don't have a DS system yet... but it seems if you had enough wear in the oil pump then this would be more likely to happen.

-

09-24-2018, 01:40 PM

#738

I've had this problem. I tried attaching a electric drill to the end of the Aviaid pump shaft to scavenge the pan. Mistake, I caused the shaft to go goofy and had to send it back to Aviaid for a rebuild.

Th Cosworth Instructions say: "Note: If the engine will go for an extended period of time without running, it is possible for oil to migrate from the oil tank into the sump. It is necessary to scavenge the engine prior to start up to avoid potential engine damage. This can be done by removing the drive belt and spinning the pump by hand until the sump is dry. Verify that there is no standing oil in the sump by checking the oil tank level."

So now if it's been a long time or the level in the DS tank looks low, I spin it by hand.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

09-24-2018, 04:16 PM

#739

Senior Member

Originally Posted by

Mitch Wright

I don't know if you could get enough oil in a cylinder to hydra lock the engine but something to consider. I would think the height of the oil tank will have an effect on the drain back as well.

Mitch, The level of the oil in my tank is about at the top of the block. I am very worried about hydra lock. I smashed a rod bearing in my 64 Chevelle sbc by hydra lock.

Originally Posted by

NevaLift2Shift

I was just about to post a similar issue. I did a first start two months ago, then let it sit, it's been seeping oil on the floor from what I think is the cam seals. The sump tank is very low now, but I bet the cylinders are filled with oil, too. I think this is just an inherent problem with dry sump systems. After talking with some other people, it seems dry sumps will eventually do this the only option is to put a shut off valve in the feed line (I don't know if I like this idea) or to drain the oil if you know it will be sitting for a bit (Apparently, a lot of race teams do this).

NevaLift2Shift, Pull the plugs, then crank it over to get the oil out of the cylinders.

I think I will put a shut of valve on the dry sump tank and hang a "remove before flight" tag on it. tag.jpg

Originally Posted by

Scargo

I don't have a DS system yet... but it seems if you had enough wear in the oil pump then this would be more likely to happen.

Scargo, I think with enough time, oil will seep through any tolerance gap. That said, my pump is OEM with over 100k on it. Thanks Scargo.

Originally Posted by

Sgt.Gator

I've had this problem. I tried attaching a electric drill to the end of the Aviaid pump shaft to scavenge the pan. Mistake, I caused the shaft to go goofy and had to send it back to Aviaid for a rebuild.

The Cosworth Instructions say: "Note: If the engine will go for an extended period of time without running, it is possible for oil to migrate from the oil tank into the sump. It is necessary to scavenge the engine prior to start up to avoid potential engine damage. This can be done by removing the drive belt and spinning the pump by hand until the sump is dry. Verify that there is no standing oil in the sump by checking the oil tank level."

So now if it's been a long time or the level in the DS tank looks low, I spin it by hand.

Gator, in the 818, the pulley shaft is to close to attach a drill motor. Thanks for the Cosworth info. It tells me this is a side effect of a dry sump system I was not aware of.

Thanks All

Bob

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

09-25-2018, 06:11 AM

#740

Senior Member

All: I took a look at my tank after Bob's post yesterday. My system is similar to his, except that I have a air to oil cooler mounted in the back of the car and a spintric unit before the oil returns to the tank. The line after the scavenge pump goes high and then in the bottom of the oil cooler and then into the bottom of the spintric, effectively creating a "u" in the circuit. Now, I believe that there is a lot of air in that part of the circuit when the car is running, but also no way for the oil to drain or siphon back to the tank. Also, I am using a stock oil filter located at the extreme bottom of engine. Bob: what is the relative height of your remote filter and cooler compared to the motor? Could oil be draining back from two places? The tank and your filter/cooler?

I did run the dip stick into the tank last night and I could not detect a level, so I have no way of knowing how much oil has drained back to the engine. I last ran the car the weekend after labor day. I also know the car has sat for months without running and I have not had the oil problem described (maybe I'm dooming myself by saying that).

I wonder if it has something to do with the critical level in the engine block and the relative position of all the bits in the oiling system that can drain back to the bottom of the block. It seems that if oil were going to drain back, it would happen at some pace less than a couple of months...even starting when the car shuts off at the track. All that said, I don't know what the fitting to the inlet of the pump looks like and what the opportunity for leakage is there.

I'll try to figure out how much oil is left in my tank soon.

-

09-25-2018, 11:08 AM

#741

Rob I think you are confusing the return line from the Aviaid pump with the feed line from the tank to the bottom of the pan into the oem oil pump. Your Spintric and cooler loop are on the pressure line from the Aviad DS pump to the top of the DS tank. It doesn't matter if it is higher or has a U in it, that's not where the drain-back into the engine is occurring.

The drain-back that fills the block is coming from the bottom of the DS tank to the Pan/OEM oil pump inlet, leaks thru the OEM oil pump, and into the block. It's a very slow process, that's why it takes a long time to be an issue.

Bob IMHO putting a manual valve on that line is taking a huge chance of destroying your engine accidentally for a problem that is far less likely to occur. You only have to forget to open it once! A solenoid driven valve might make more sense like Canton sells for their Accusump. But you are still relying on that valve opening 100% of the time when you flip on the ignition.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

09-25-2018, 01:39 PM

#742

Senior Member

Originally Posted by

Sgt.Gator

Bob IMHO putting a manual valve on that line is taking a huge chance of destroying your engine accidentally for a problem that is far less likely to occur. You only have to forget to open it once! A solenoid driven valve might make more sense like Canton sells for their Accusump. But you are still relying on that valve opening 100% of the time when you flip on the ignition.

Gator, I agree with you on the chance of accidently leaving the oil off.

I don't like the solenoid valve. to much chance it would stick shut.

I need to find a full proof method.

Bob

-

09-25-2018, 01:44 PM

#743

Senior Member

Originally Posted by

Rob T

All: Bob: what is the relative height of your remote filter and cooler compared to the motor? Could oil be draining back from two places? The tank and your filter/cooler?

Hey Rob,

Oil filter is at top of block and oil cooler is bottom of block. See picture.

Bob

oil.jpg

-

09-30-2018, 08:31 PM

#744

Senior Member

Hi: Here is some "drain back" data from my dry sump. The last time I ran my car was September 7. It has not run since then. Today, I measured the level in the dry sump after sitting 23 days. It was 11.5 inches from the top of the tank. I then ran the car around the neighborhood for 20 minutes. The oil was about 180F and the water temp was about 195 F. I waited a few minutes and measured the oil in the tank. It was 8.0 inches from the top. So....the difference between sitting for 23 days and hot was 3.5 inches. There are some baffles inside the tank, but assuming the tank is between 5.5 and 6.0 inches in diameter, the difference in volume was between 1.4 and 1.7 quarts. This is the oil that had presumably moved to the bottom of hte block. I have never had an issue with starting the car after sitting for a couple of months. The pressure comes up right away and there is no issue with the dry sump. I know that the scavenge capability of the pumps is many times the oil flow to the engine.

I will get a measurement every day until my next track day and see what the rate of flow back into the engine is. More to come....

-

10-01-2018, 12:28 AM

#745

Senior Member

Originally Posted by

Rob T

Hi: Here is some "drain back" data from my dry sump. The last time I ran my car was September 7. It has not run since then. Today, I measured the level in the dry sump after sitting 23 days. It was 11.5 inches from the top of the tank. I then ran the car around the neighborhood for 20 minutes. The oil was about 180F and the water temp was about 195 F. I waited a few minutes and measured the oil in the tank. It was 8.0 inches from the top. So....the difference between sitting for 23 days and hot was 3.5 inches. There are some baffles inside the tank, but assuming the tank is between 5.5 and 6.0 inches in diameter, the difference in volume was between 1.4 and 1.7 quarts. This is the oil that had presumably moved to the bottom of hte block. I have never had an issue with starting the car after sitting for a couple of months. The pressure comes up right away and there is no issue with the dry sump. I know that the scavenge capability of the pumps is many times the oil flow to the engine.

I will get a measurement every day until my next track day and see what the rate of flow back into the engine is. More to come....

Rob

Your observation confirm what I was seeing in post #734 above. I think if you let it sit longer, it would continue to transfer oil to the block. Eventually getting to the piston level. Though the ring gaps and the out the exhaust valves.

I think if you visit the car every day, you will have a hard time not starting it.

Bob

-

10-01-2018, 09:19 AM

#746

Senior Member

I never had issues when I had the car. Heck, my Porsche 911 race car sits longer and never has any issue either.

Thanks- Chad

818R-SOLD!!!- Go Karted 7/20/14/ Officially raced NASA ST2- 2/28/15

2016 Elan NP01 Prototype Racecar Chassis #20

1969 Porsche 911ST Vintage Race Car

1972 Porsche 911T (#'s matching undergoing nut & bolt resto in my garage)

-

10-02-2018, 12:55 PM

#747

The season finale for the NWMECS Enduro Championship. CRR and Retro Racing came together to take 1st Pace in the 4 Hour Enduro and 2nd Place in the 2 Hour Enduro. It was great racing at Portland International Raceway. Big thanks to our Sponsor, Subaru of Bend. Your continuing support and shop work has made it possible to be competitive in endurance racing with our STI. And thanks also to our tuner, Surgeline.

We would have taken first or second in the 8 hour if a suspension bolt hadn't fallen out.

One of the RR Team drivers was in the car on the last lap of the 4 hour Enduro when things went badly. He'd just gone into the chicane when he lost all power and the car spun out. A turn worker came over and told him the right rear wheel was cocked out at a 30 degree angle.

Towed in on a trailer. We quickly determined the upper suspension bolt tying the coilover to the hub had fallen out. We found a bolt and put it back together with an eyeball camber setting.

But still no go forward. Further checking found the left rear CV axle had sheared off inside the outer CV boot. We called every auto parts store and dealer in the Portland metro area, no one had an STI CV axle. So we welded the broken one back together. That lasted 6-7 laps, which was 5-6 more than we expected. It was too bad, we were doing great in the 8 hour up to that point.

I'm not complaining, I'll take a First and Second anytime!

The good news: The engine ran great. There no issues with oil pressure, oil temp, coolant temp, or tranny temp. And PIR is a 75% of the time WOT track. The Subaru EJ257 showed it can handle 4 hours of being thrashed, and showed no signs it couldn't go another 4 hours. We would have had to add oil though, for sure. Easy in the DS tank in the trunk.

I have a new system for the dry sump. On the head valve covers the two rear ports are tied to the oem balance bar and oem block port. So they are still all oem.

The front ports are teed together, then teed to the back block port that used to be the PCV port. From there the line goes thru a -12An fitting that has a 1/8"npt port. The port has a 1/8th" npt nipple with a vac hose to a Vac/Boost gauge on the dash so I can monitor what is happening for blowby gas pressures. From there it goes thru a Vibrant one way check valve. When the DS pump is pulling vacuum the check valve closes and I get the benefit of block vacuum. When the engine is running full tilt and the DS pump is no longer able to create vacuum, the check valve opens and allows the blow by to vent to the DS tank. The Vibrant valve works really well, it's part of the Vibrant E-Vac system for using the exhaust gas stream to create a vacuum in the engine block, so it's good for high temps. Part #: 11192, Description: One Way Check Valve, Flapper Style, -12AN (Male AN Flare to Male AN Flare)

It's been a great season. I have a couple of more track days left at ORP to do some testing on the 818R and the Palatov before the cars go into hibernation.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

10-02-2018, 09:24 PM

#748

Senior Member

Gator: Good to hear you had a successful and safe weekend. Also that your EJ held up well. That's encouraging.

-

10-14-2018, 08:20 PM

#749

Senior Member

Hi: Here is the data from my dry sump. I measured the drop from the top of the tank, which is approximately 20 inches tall. I then approximated the diameter of the tank as 6". I used a calibrated dip stick and measured the level of oil in the tank over time, from hot and recently shut off out to 23 days. At shut down, I'd estimate between 5 and 6 quarts in the tank. The tank bottom is at the bottom of the engine. Actually, the drain fitting is accessible through the diffuser plate (nice work Chad).Quarts drained from dry sump.jpg

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

10-14-2018, 08:21 PM

#750

Senior Member

So in 23 days, about 1.7 quarts drained back from the dry sump tank. Notice that the rate was slowing, as well. I have never had an issue with smoke or any other issues starting the car after extended down time.

-

10-14-2018, 08:22 PM

#751

Senior Member

BTW....the left axis is quarts of oil and the bottom axis is time in days.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-15-2018, 01:12 PM

#752

Senior Member

Originally Posted by

Rob T

BTW....the left axis is quarts of oil and the bottom axis is time in days.

Hi Rob,

My tank may be higher and bigger diameter. Also it sat for a longer time.

tank.jpg

When the oil makes it to the to the level of the piston rings, it will start filling the cylinders and exhaust manifold.

I am going to put a manual valve on the dry sum tank line. The valve have a switch connected to the starter solenoid wire.

Bob

Last edited by Bob_n_Cincy; 10-16-2018 at 12:06 AM.

-

10-15-2018, 08:17 PM

#753

Senior Member

Bob: Your tank is definitely larger diameter and much higher in the car. The bottom of my tank is below the transmission. The head pressure difference would be substantial.

-

12-24-2018, 05:17 PM

#754

As ya'll know I am an advocate for dry sumping your Subaru engine. But if there was a cheaper way without the added complexity and potential failure points....

Which led me to looking at Saker cars (again). Although they are almost unknown in the US, and don't seem to be taking the world by storm except in the Netherlands, they have been around for 16 years under various owners on different continents and are still making some very fast Subaru powered cars. It looks like they have a new website, at least since the last time I looked at them:

In digging around they claim up to 2.0 G cornering, and they don't use a dry sump or any kind of Accusump/Moroso accumulator. Part of the reason is they are essentially a stock powered EJ22 at 275 HP. But that explains the reliability except for the oiling.

I found the Owners Manual, Service Manual, and Parts catalog at their website. They have a very complete parts catalog, down to specific fasteners, if only FF could have a parts catalog like that!

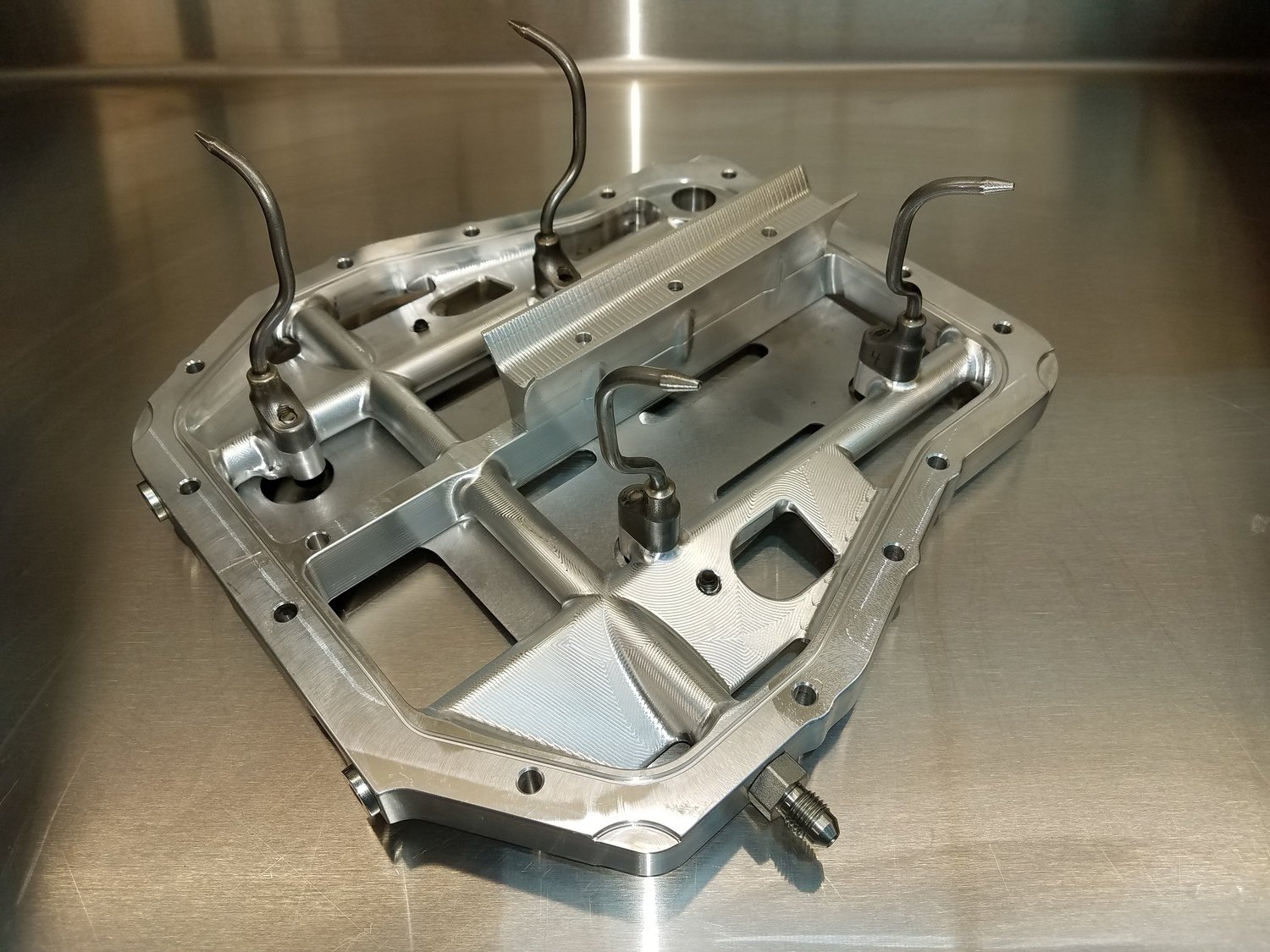

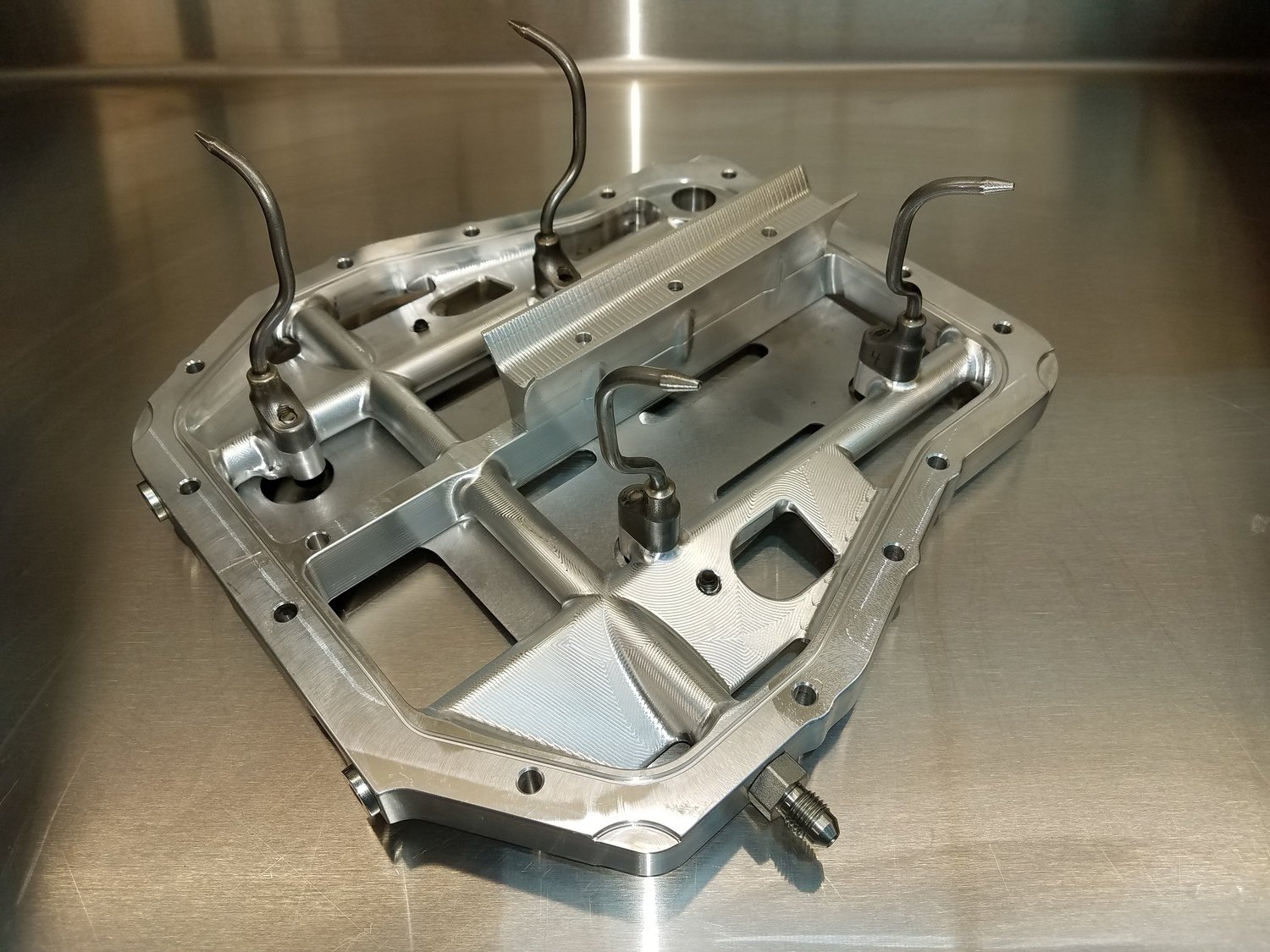

They have two items that are unique to their wet sump system. A plate that goes between the block and the sump pan, and the sump pan itself. With the magic of Photoshop I was able to enhance the parts catalog image to see what is inside the pan:

I don't know if you have to be a Saker owner to buy these parts. I've emailed them but of course it's Holiday time so I don't expect to hear back from them for awhile.

Merry Christmas everyone!

PS: And if you're looking for a last minute Christmas present:

https://www.belmitdevelopment.com/st...902/category=0

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 1 Thanks, 4 Likes

-

12-24-2018, 08:58 PM

#755

I spend quite a bit of time researching wet sumps and along with the Subaru’s running the VLN series I came across Saker Cars. I started emailing s guy from Saker when I made the decision run a wet

sump. I have to do some digging because I don’t recall his name but very helpful. The photos of the pan he sent looked much like a Cosworth pan along with photos of the oil control plate. I have actually made a copy but haven’t used it. Since I have installed Bill Walkers plate, it takes the concept 4-5 steps further. I have data before and after the plate. Before the plate I had good oil pressure at all times (65lb or higher at 220* oil temp) is was seeing some slight (maybe 7psi) fluctuations. With Bills plate the fluctuation is gone.

Last edited by Mitch Wright; 12-28-2018 at 10:53 AM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-24-2018, 08:59 PM

#756

FYI I think Retro has or had a Saker in their shop

-

01-01-2019, 11:06 PM

#757

That oil squirter plate is pretty inexpensive considering the amount of 3D contour CNC work is on it.

-

01-02-2019, 01:51 AM

#758

Originally Posted by

Mechie3

That oil squirter plate is pretty inexpensive considering the amount of 3D contour CNC work is on it.

Shockingly inexpensive. Must be run on one hell of a fast machine. Plus, you have the squirters to fabricate - perhaps even hand-bent and brazed onto those bases.

-

01-03-2019, 12:15 PM

#759

The squiter plate also has some of the features of Bill Walker's oil control plate. The raised section is a crank scraper, but it's unlike any crank scraper I've seen on a Subaru before. From their website: "We have also integrated a three part aluminum and steel windage tray/baffle system into the oiler plate to ruduce power robbing oil windage and help return the oil to the sump as fast as possible."

The Cosworth crank scrapers are quite different:

Bill's scrapers:

However I doubt there was any in depth engineering analysis done on how large the squirter jets should be (orifice size) or what effect they will have on oil pressure. I'm guessing (hoping) the designer copied the Subaru OEM oil squirters they used to include on many of their performance engines.

"We recommend at least the 11mm oil pump, but prefer the 12mm pump to supply the additional volume needed. The 12mm pump yields 100psi cold start pressure and 60-80psi warm at 2500-3000rpm cruise with 15w40. 20-40psi at idle depending on temp and oil used."

I'd like to see what they get at race rpms and heat. Such as 7,000 RPM at 220 degrees.

The oil feed has to be from an external pump like a dry sump, or some sort of split off the oem pump. I'm not sure how I would hook it up. Possibly a AN line from a port on the block using the oem pressure, like the turbo feed line on the passenger side but use a port on the driver side, or on the top of the engine:

It helps to read the instructions! : "Simply run a T fitting off of the oil pressure port on top of the block and -4AN line down to the plate and your ready to go."

I could probably tee a 4AN line from the pressure side of my dry sump on it's way back to the DS tank , or even a 3an to really restrict the volume. It would need some testing. Then there would be no affect on the oil pressure for the rest of the engine. And if the oil has some air mixed into it from the scavenge it doesn't matter because it's only being used to wash down the bottom of the pistons.

Last edited by Sgt.Gator; 01-03-2019 at 01:14 PM.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

01-03-2019, 02:26 PM

#760

I did remove the KB windage tray when I installed Bills plate. FYI looking back at my data it looks as though the oil temp is about 10* lower with Bills plate. More data will verify but that is what I have noticed comparing before Bills plate and after Bills plate data.

Gator, have you been able to finish up your 818R and plan to have it out this spring?

Last edited by Mitch Wright; 01-03-2019 at 02:31 PM.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote