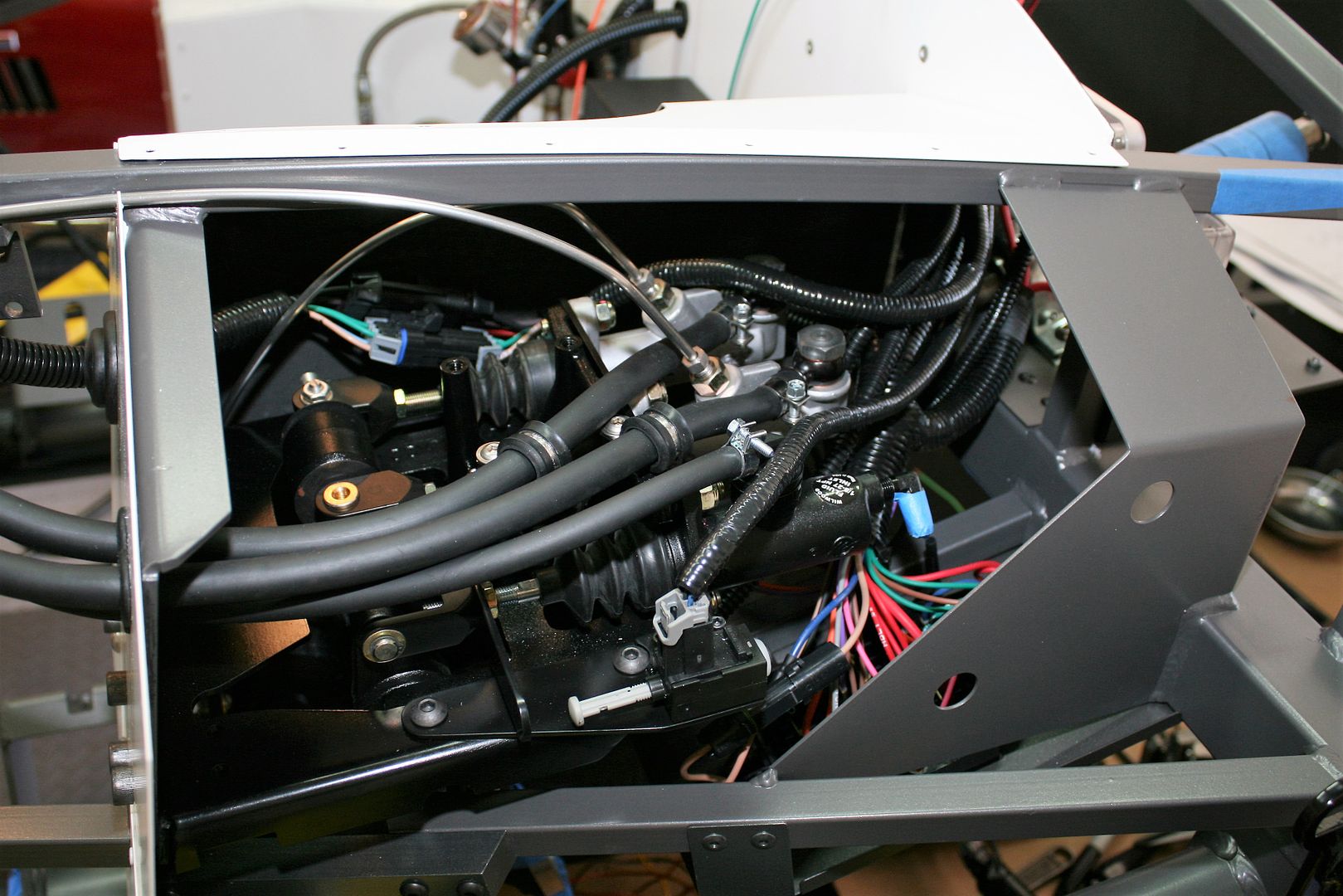

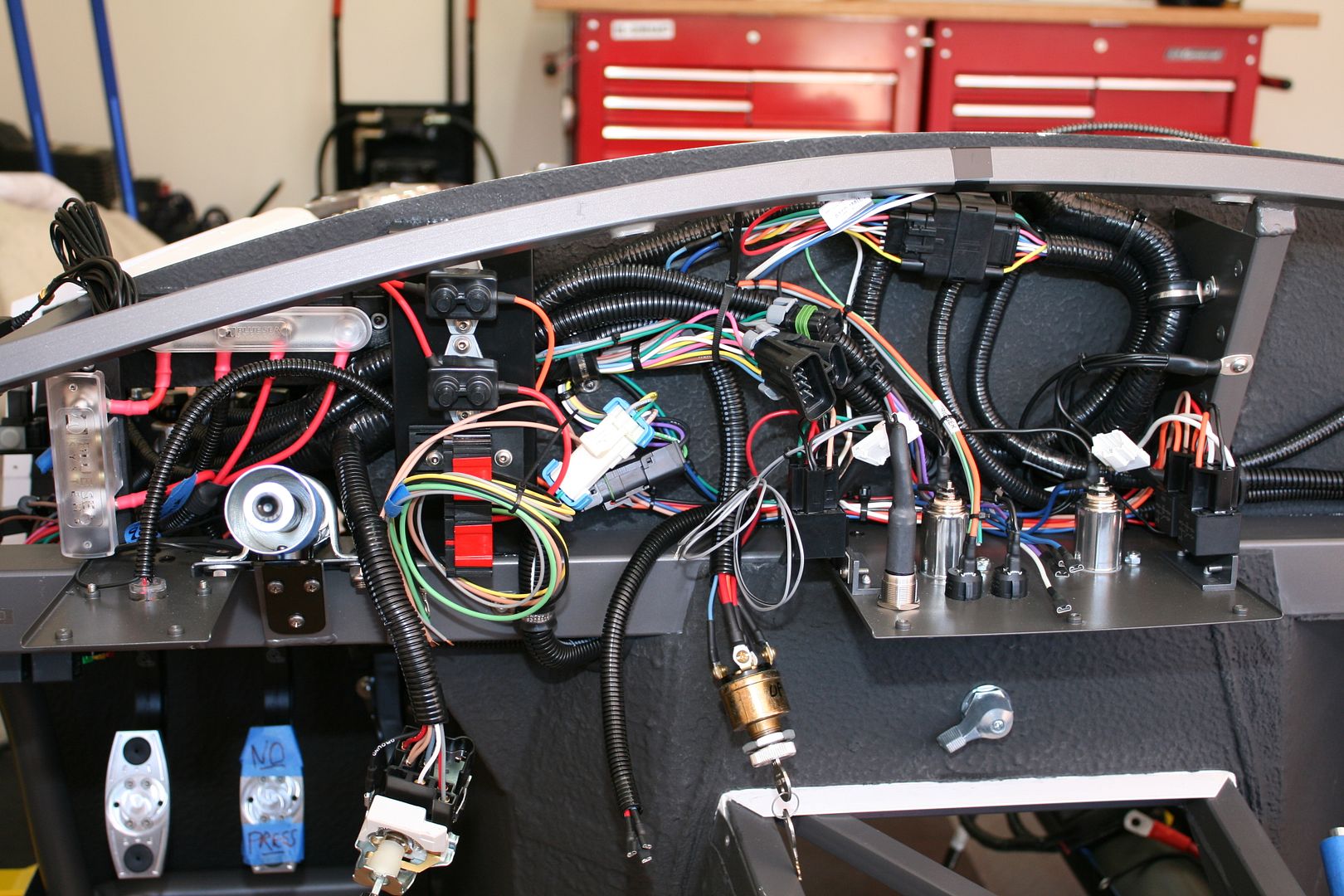

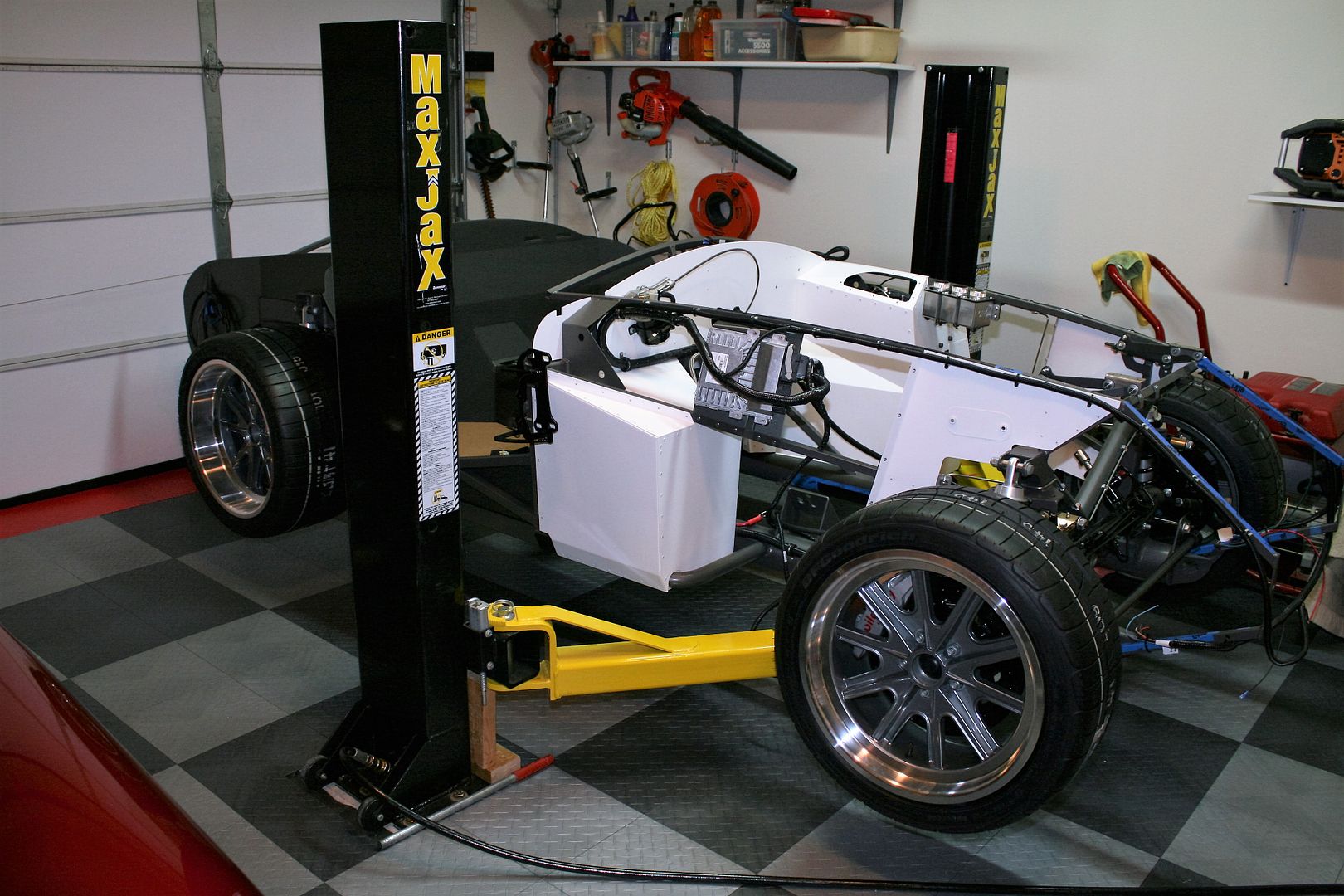

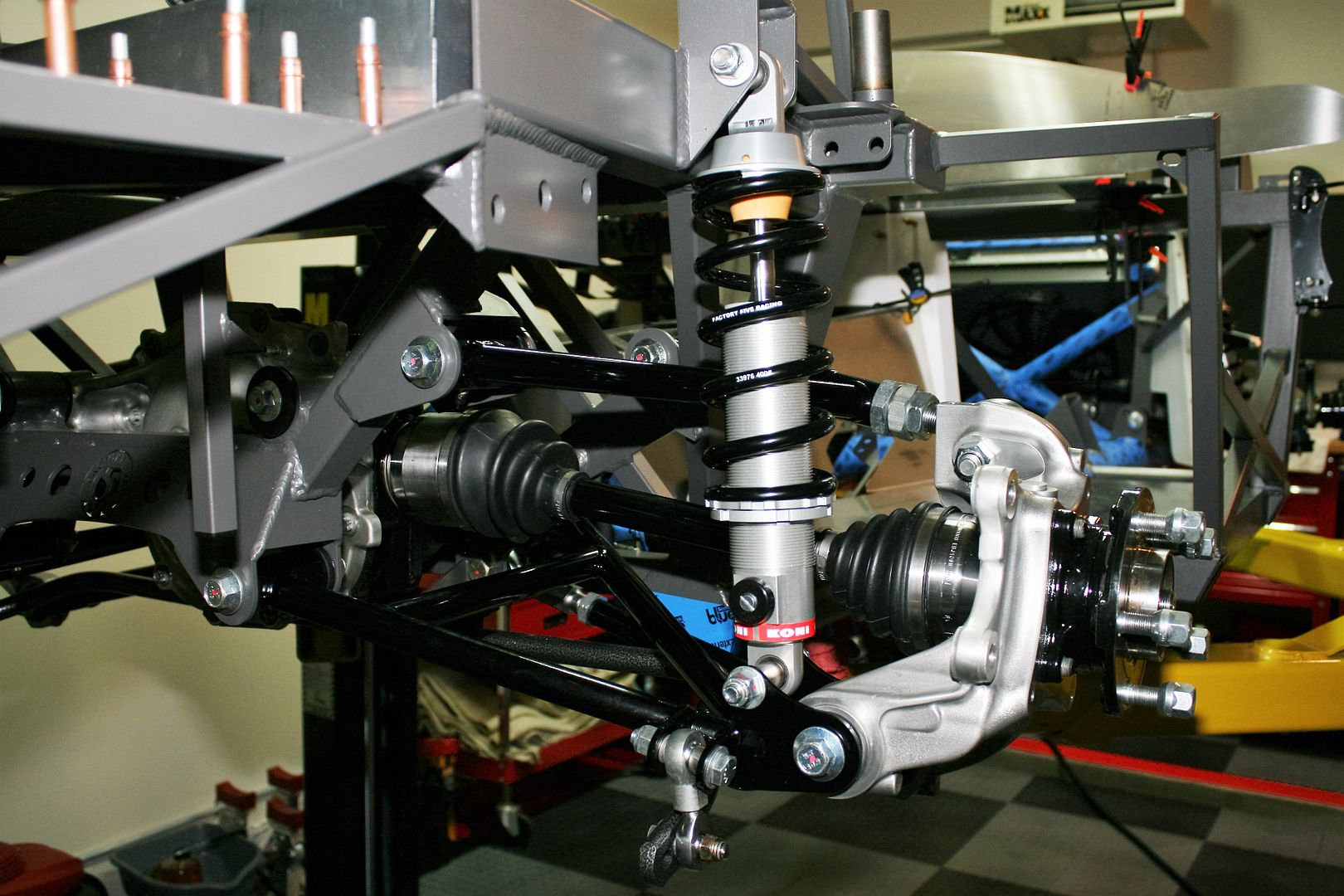

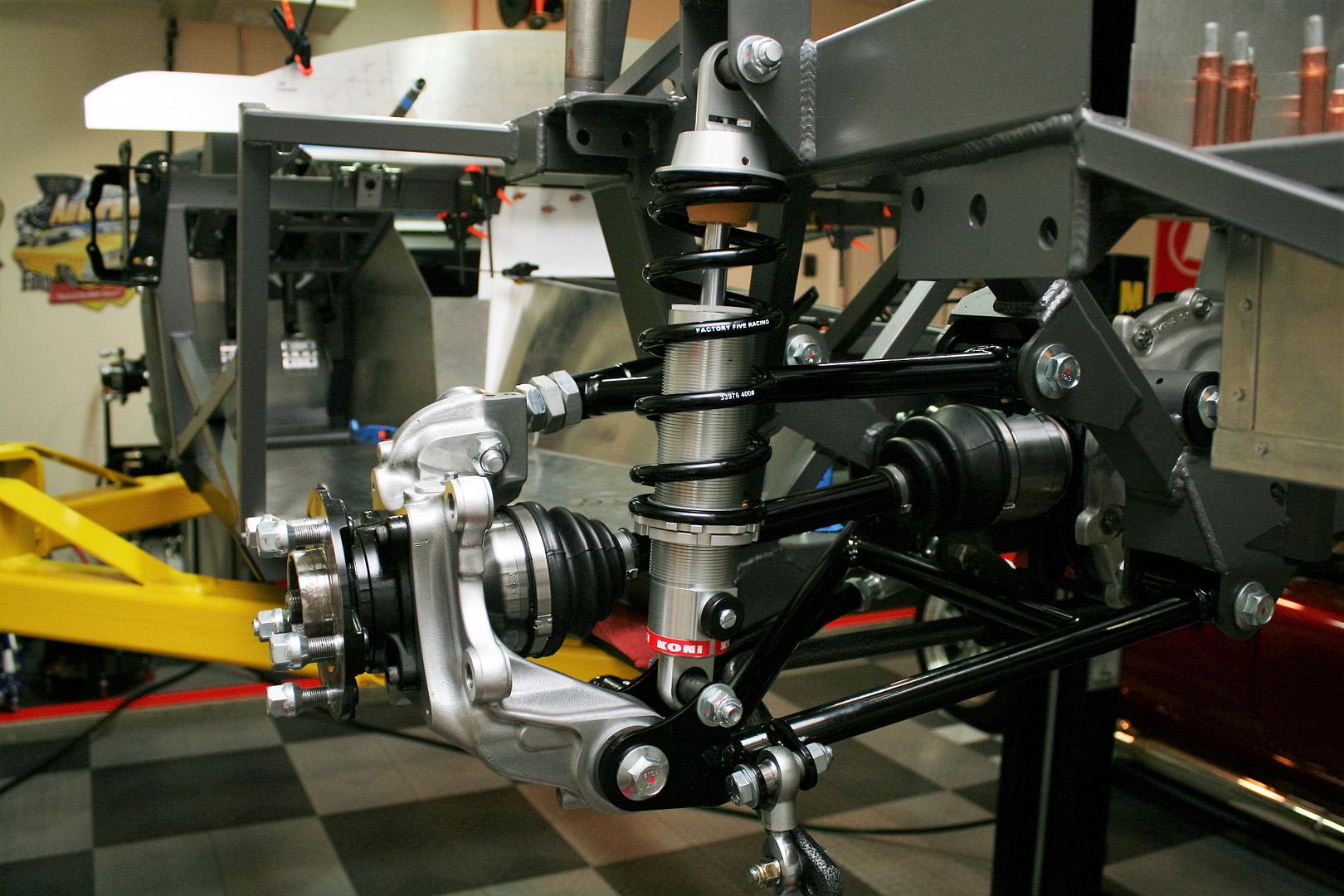

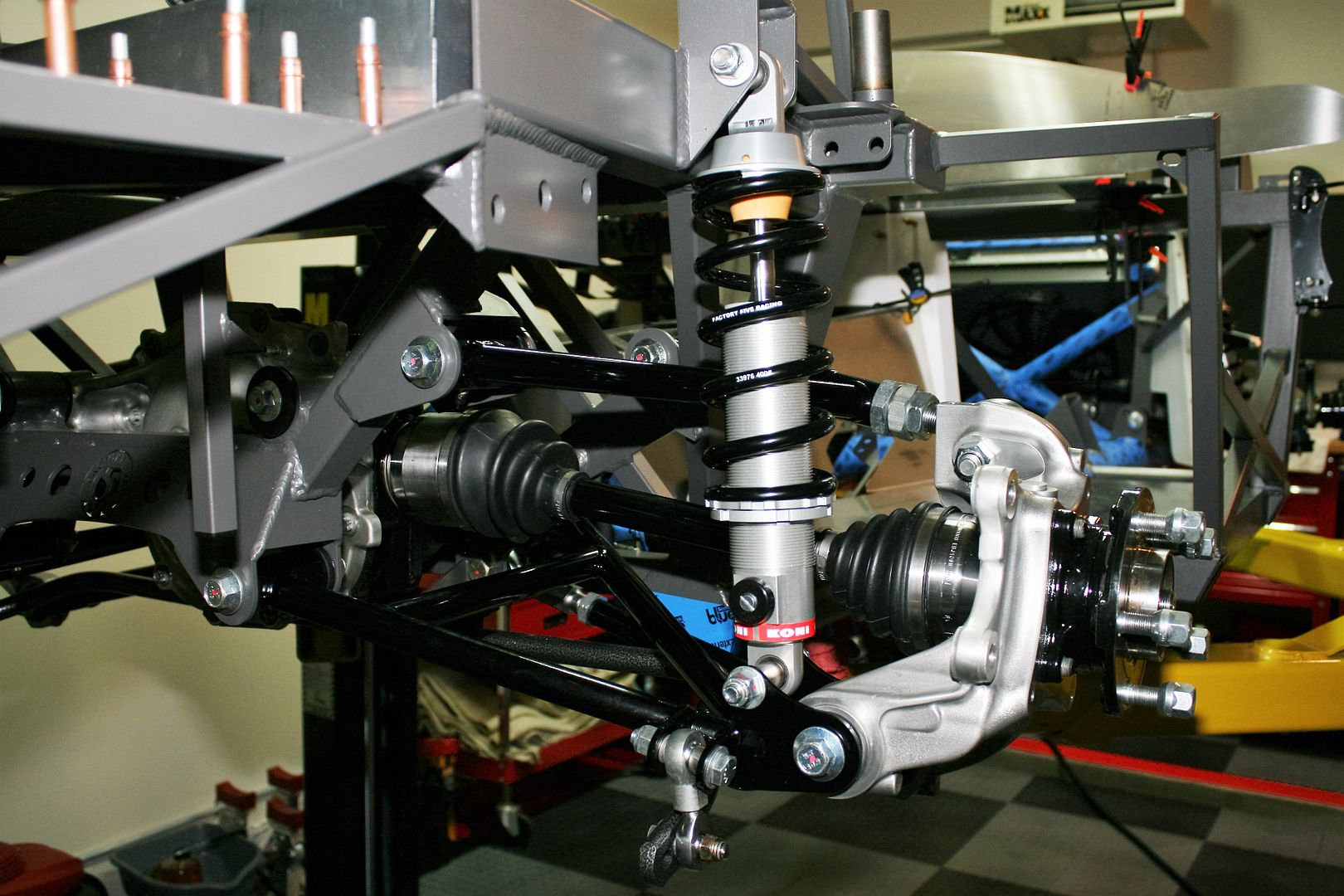

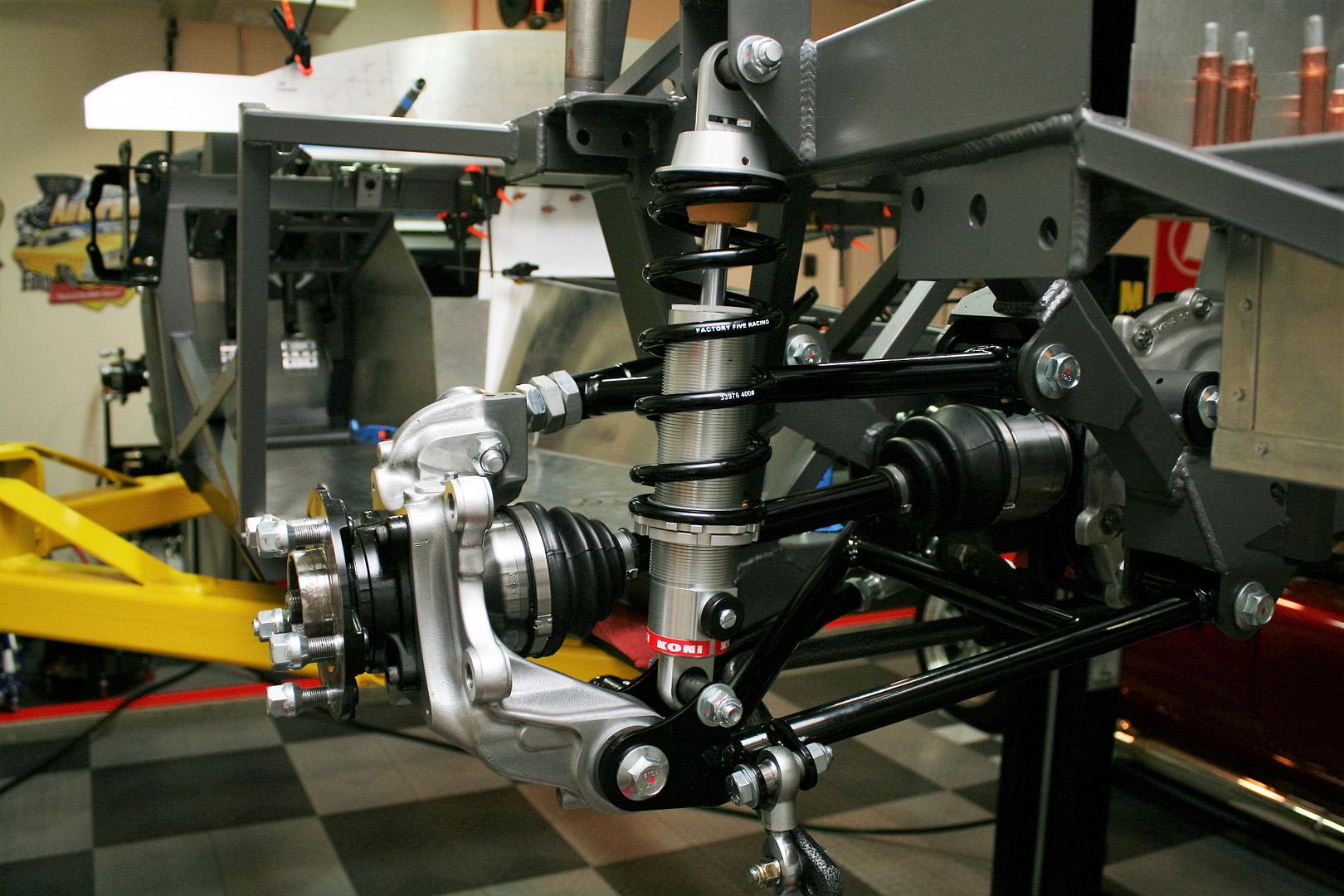

Ok, so finally to the actual IRS assembly update. Last week I received my upper and lower control arms. I was still missing a few of the bolts, but was able to assemble everything into the chassis using some temporary hardware in a couple places. Everything works, and it turned out great. But a couple things I learned and offer as recommendations. Iíve tried it both ways, and have decided I like to grease these large poly bushing/sleeved joints BEFORE assembly. Once the joint fills with grease and squirts out around the little holes between the bushing and the sleeve, Iím now 100% sure theyíre properly lubed. I smear that little extra grease on the bushing end, and it makes it way easier to assemble. For the most part, everything fits really tight. Some adjustment of the tabs might be necessary before anything will go in. I have a big Ford wrench (how many know what that is?) I got from my grandfather that works great for adjusting the mounting tabs. A big adjustable (Crescent) wrench also works. Just make sure the jaws are clean and tight before applying any pressure. Then you won't damage or mark the powder coat. I found the upper control arms especially tight to get in place. A dead blow hammer doesnít hurt sometimes either. I found those tapered pins I made to install the center section, mentioned in an earlier update, work GREAT for helping to line up pieces as they were getting close. Drive the taper through, everything centers, and then the bolt almost pushes in. Iím saving those things. Also had to adjust the lengths slightly on a few of the supplied sleeves. All pretty normal stuff. I followed the assembly sequence exactly as described in the instructions, and torqued when they said to. The CV axles also went in just the way the instructions said. It took a little bit of a bump with the dead blow to get the inner retaining ring to click into place. Today I received the last pieces of hardware, so installed those and final torqued and marked everything. The only thing remaining is the axle nut. I ran it down with my puny air impact wrench. But I wonít be able to get the final tightness until I have some brakes or the drivetrain installed to hold it. I did make one very small change. When I installed the rear sway bar, the two threaded together rod ends were at a pretty sharp angle vs. straight up and down when the suspension was level. So I trimmed the one longer bushing by 1/8 inch, and added another 1/8 spacer on the other side. Much better. Itís not very much. Maybe just the tolerance of the bends in the sway bar.

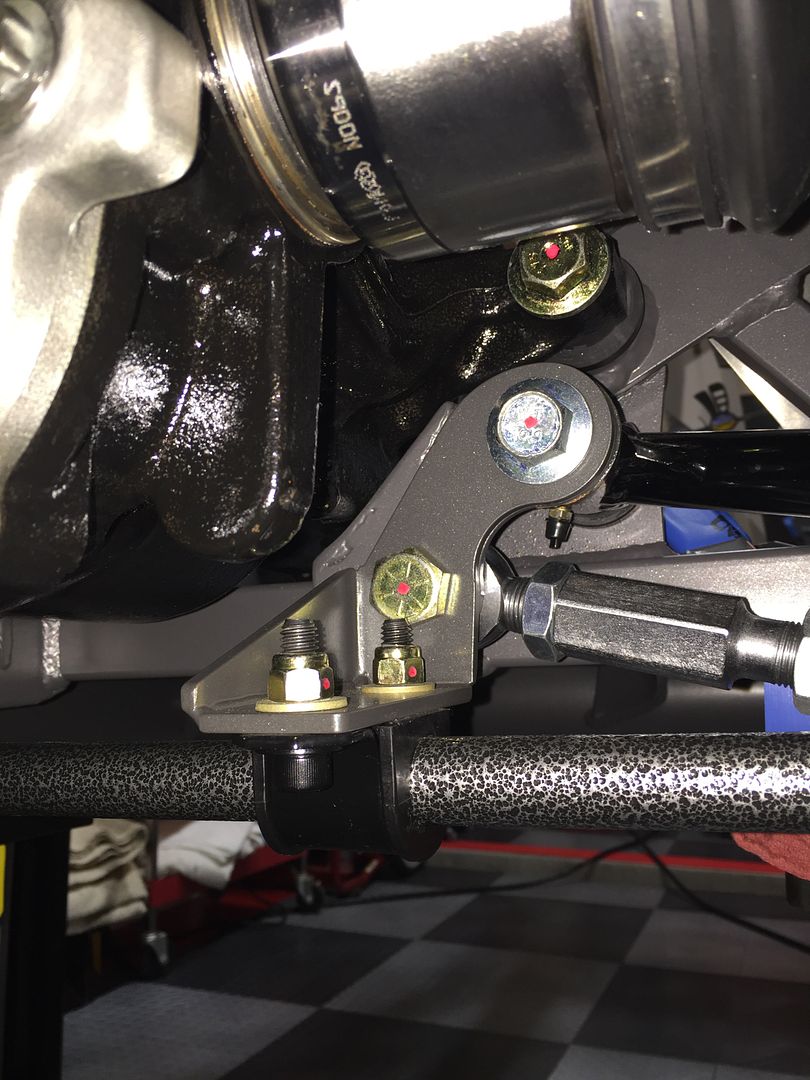

Iíve had a couple questions about the two lower cross-axis joints in the Mustang knuckles. They are not replaced, but used as is. The main joint (the rear one) fully pivots and turns. Like a Heim joint. It appears to be a heavy duty and well made piece. The toe arm joint (the front one) is some type of elastomer, and just flexes once bolted down. Itís pretty large and flexible. The instructions clearly state to torque the bolt down with the suspension in the level position. Makes sense. You can feel some resistance from the joint when moving the suspension up and down. The top joint is the bolted in large rod end showing in the pictures, which comes with the kit. Hope this all makes sense. Iím learning about this stuff for the first time.

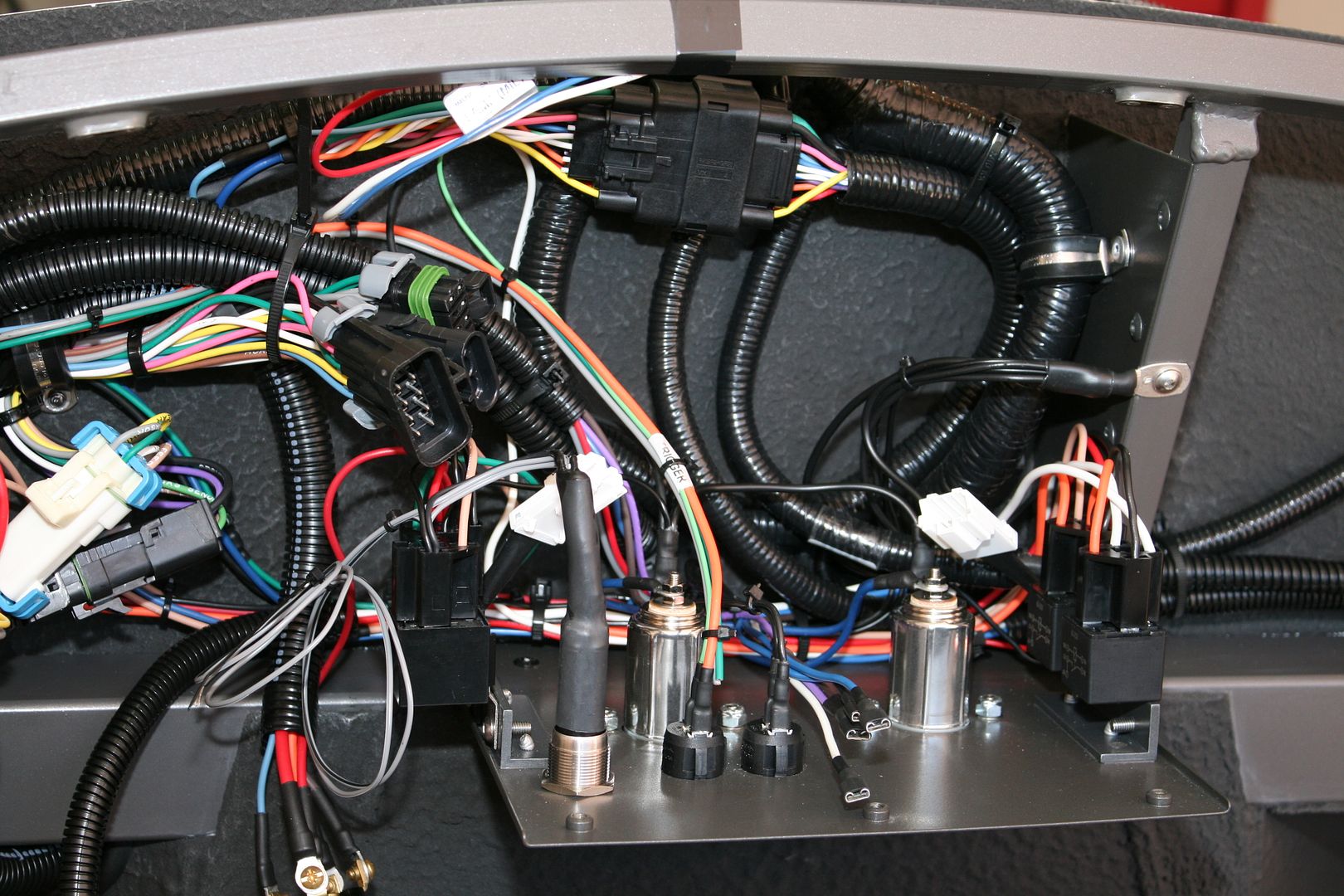

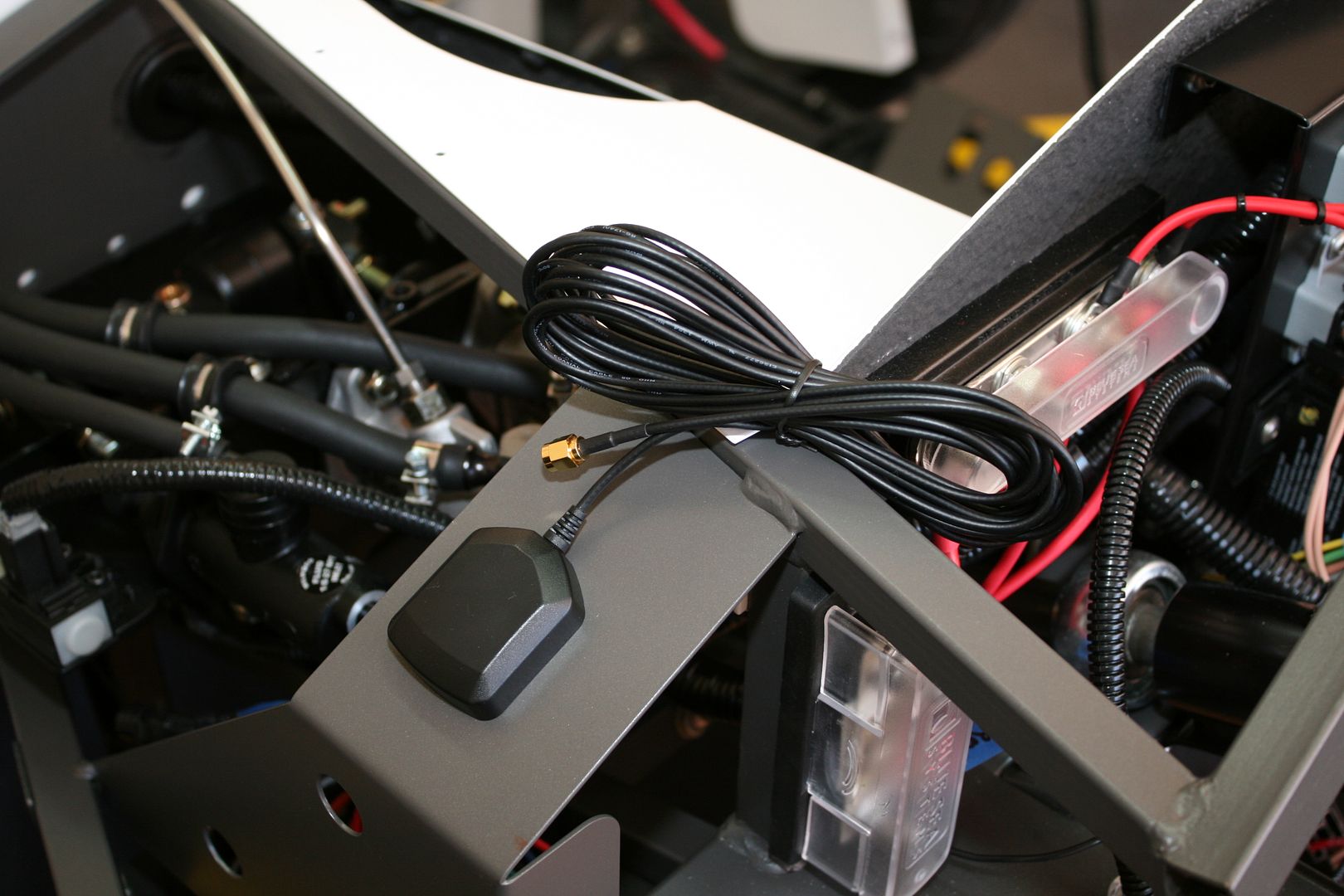

So here are some pics. Really not much else to say. I think it turned out great and looks really good. Looks an awful lot like what we saw at Factory Five during the open house. But makes a difference when itís really your car. Everything turns nice and smooth. Just need to remember to add fluid at some point.

Passenger side from rear. Note in all the pictures the suspension is drooping, as it would with the chassis on the lift. The final position is the upper control arm and CV axles level, and the lower control arm pointed slightly down. Note also I havenít done anything with alignment yet.

Passenger side from front. Note the large adjuster for camber. The toe adjustment is a little harder to see on the inner part of the lowest arm. Note none of these have to be disassembled for adjustment. Just loosen the jam nuts and adjust in place.

Driverís side from rear. Looks kind of like the passenger side.

Entire IRS from back.

Looking up.

Closer look at the passenger side from the bottom. Can see the toe arm adjustment a little better here.

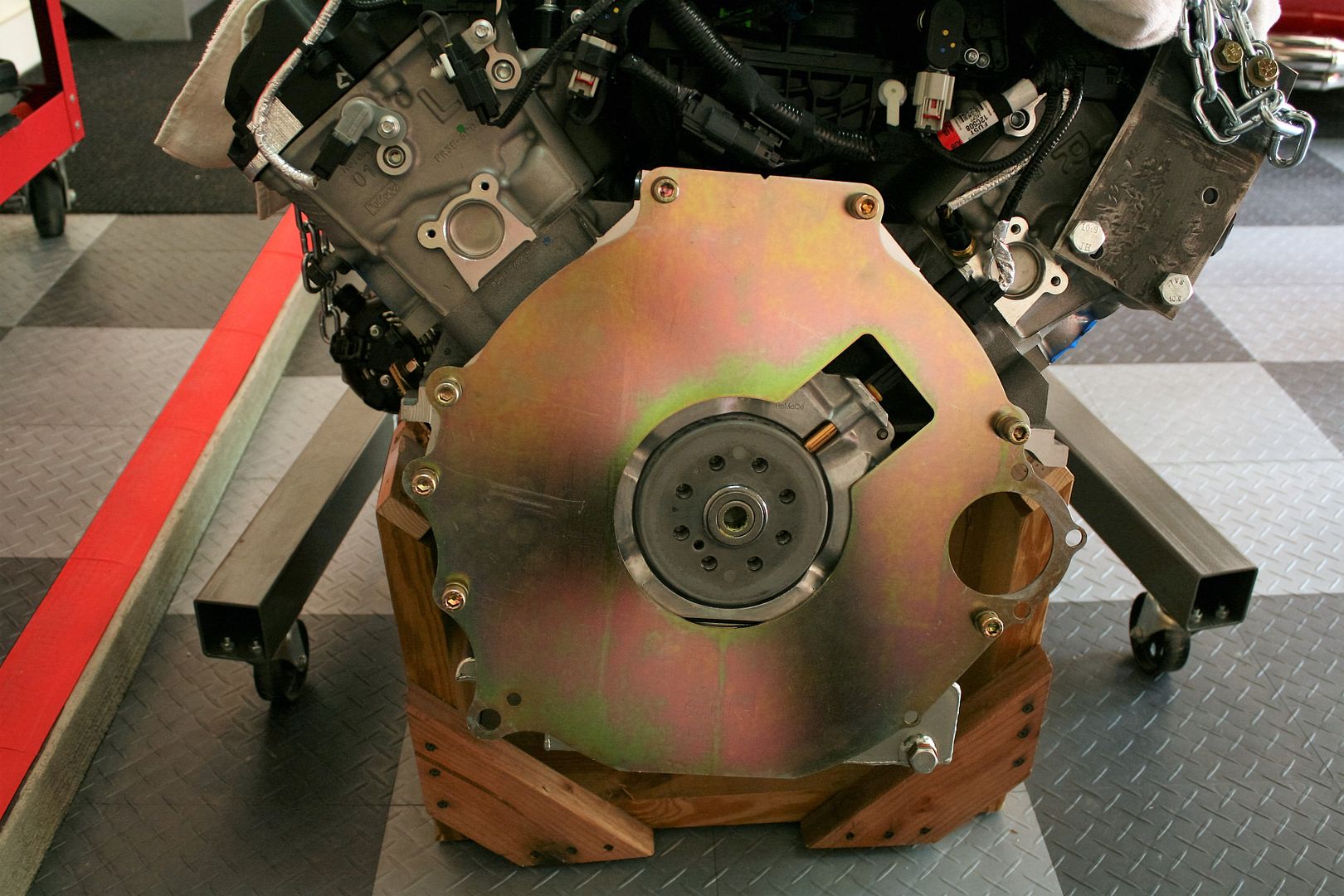

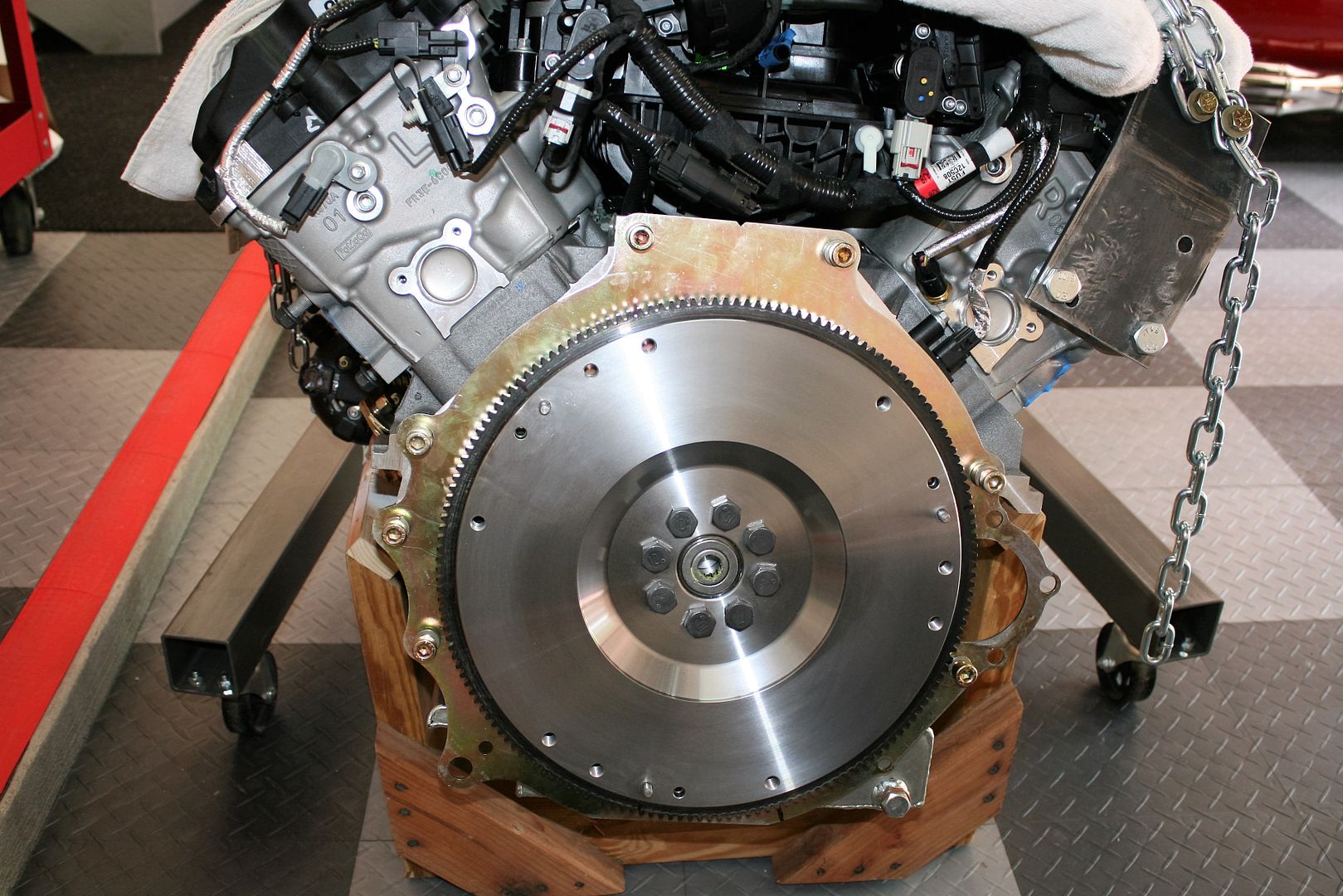

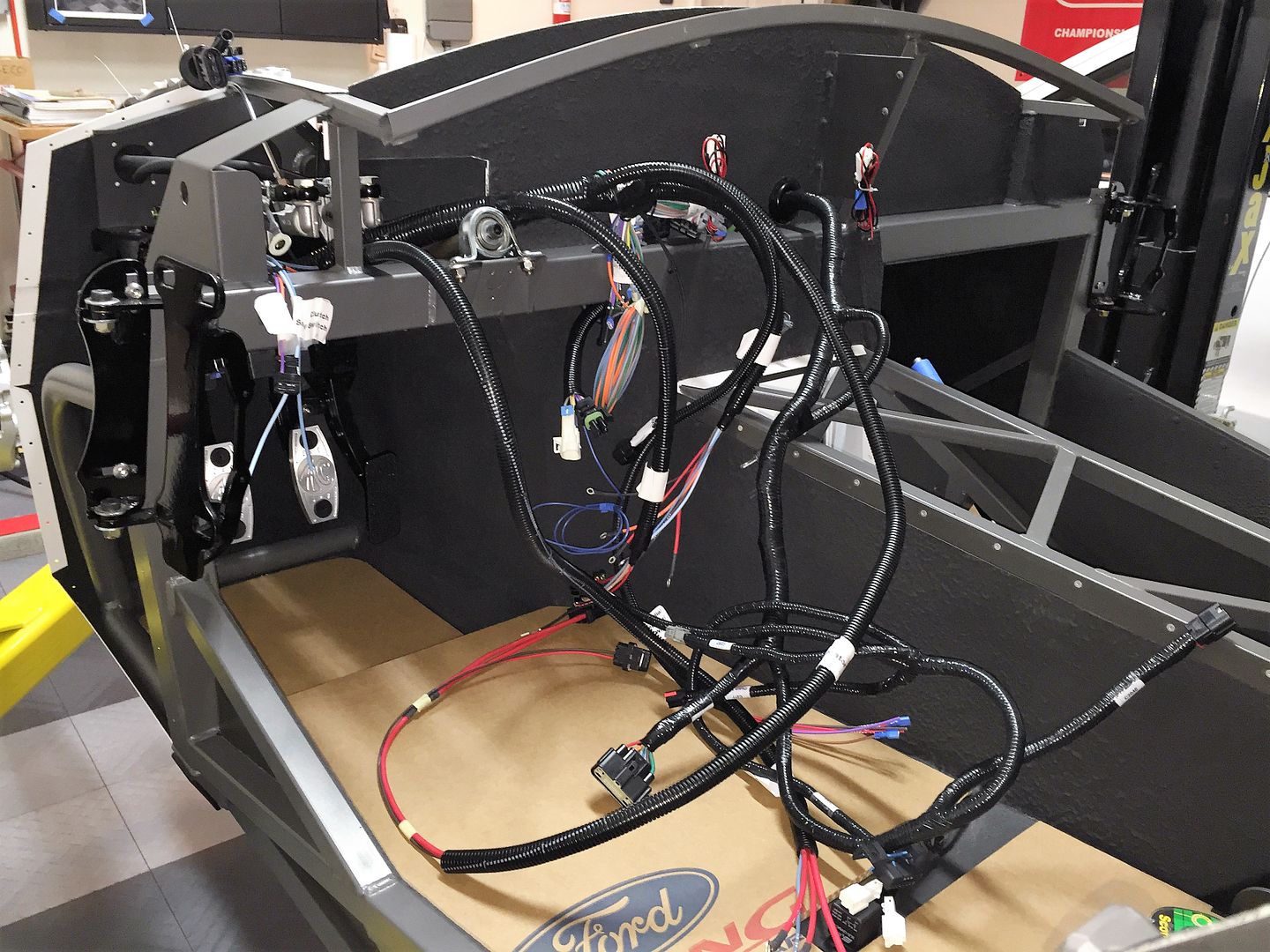

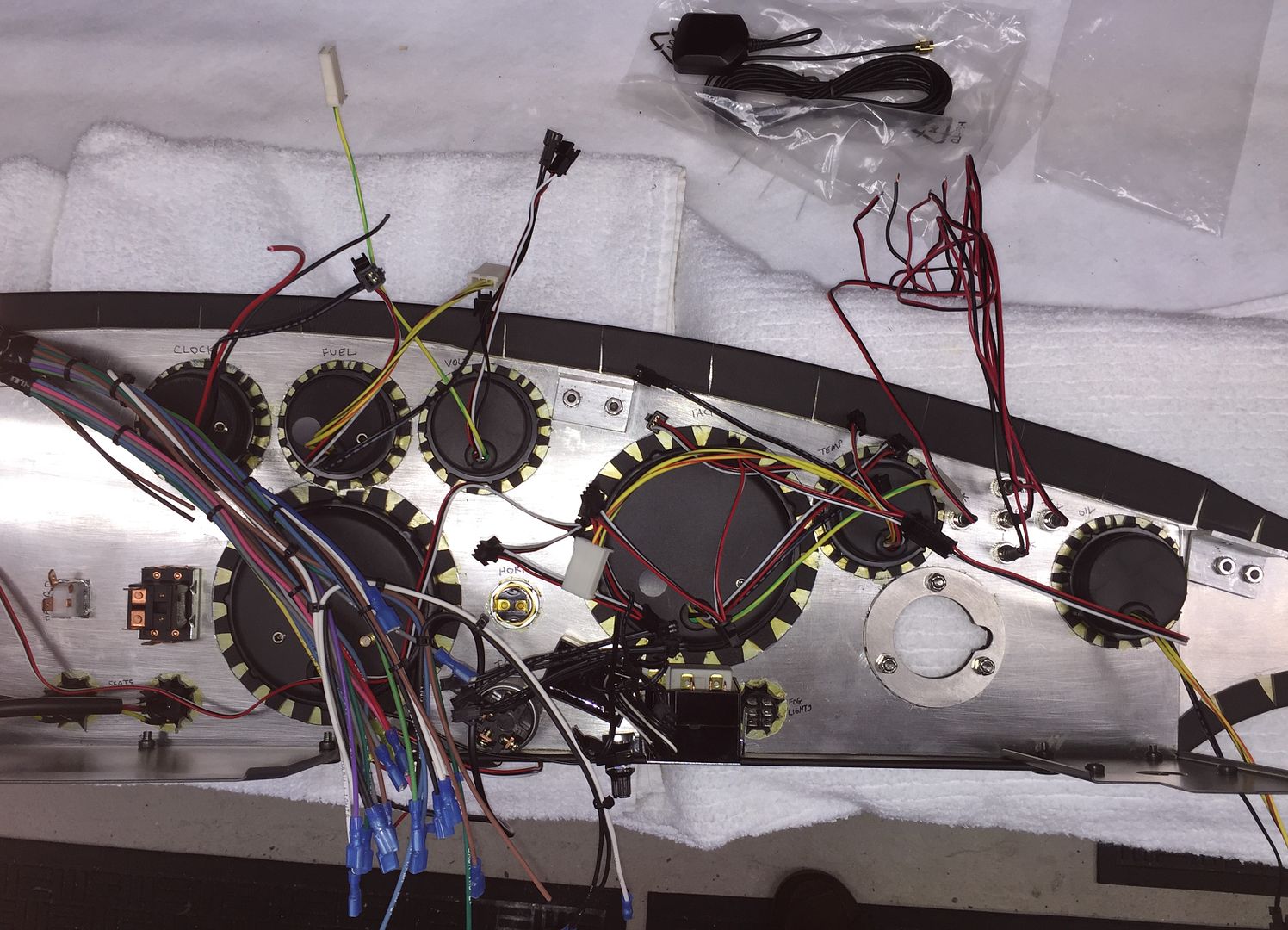

Well thatís it. Pretty cool. Tomorrow Iím going to be finalizing my Coyote engine order. Thatís next up.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

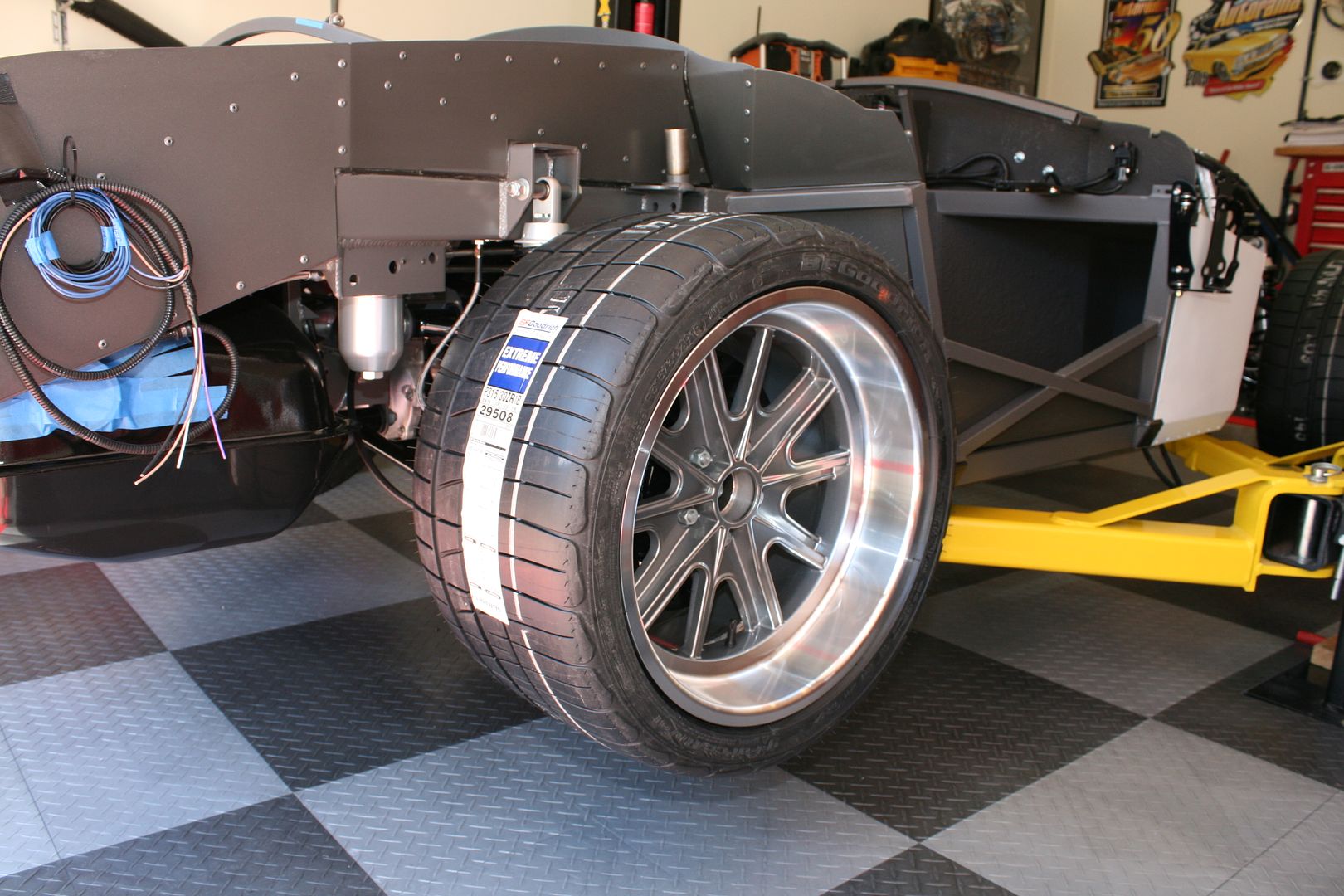

The weight for the tires exactly matches the UPS shipping weights, and they don't come with anything except a few nylon bands between the two tires. The weights for the wheels are slightly more than the 21 and 23 lbs FF lists on their website, but those are also marked as estimates. I'd be curious how these numbers stack up to the similar size 17's on #7750, but I'm not going to take them off to find out.

The weight for the tires exactly matches the UPS shipping weights, and they don't come with anything except a few nylon bands between the two tires. The weights for the wheels are slightly more than the 21 and 23 lbs FF lists on their website, but those are also marked as estimates. I'd be curious how these numbers stack up to the similar size 17's on #7750, but I'm not going to take them off to find out.