Hey guys,

I'm from the 818 forum, fitting a VR6 turbo in and using a G50/01 trans.

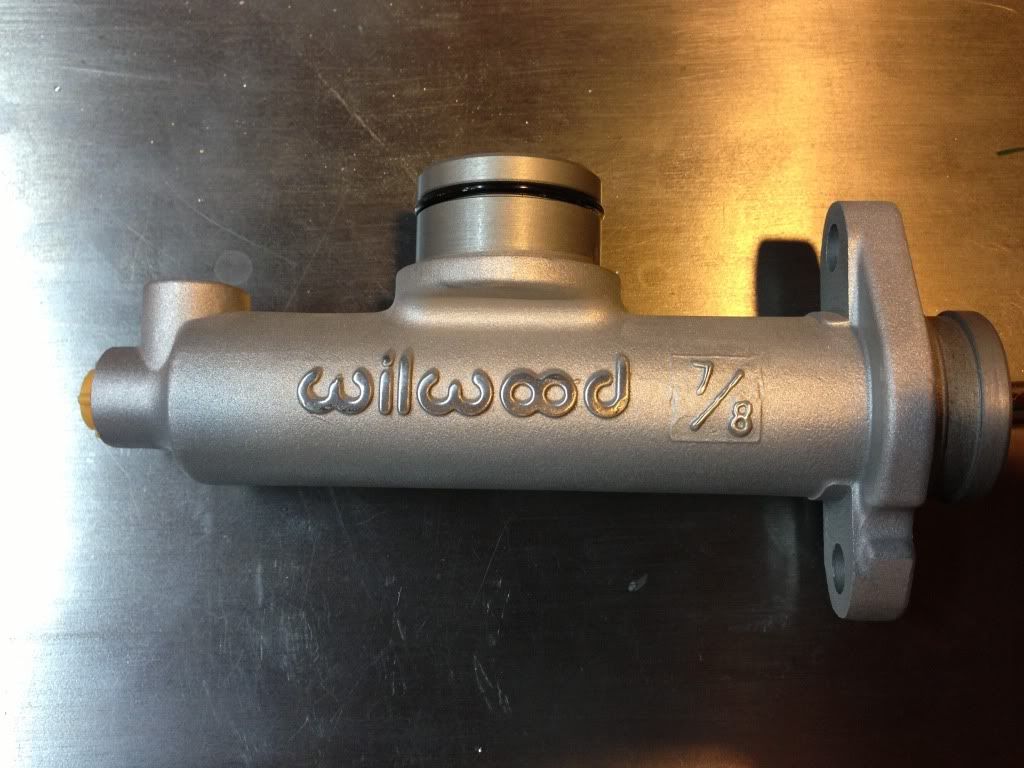

I know many of you are using a G50 (/52 probably) with your big V8 powa. I have come to the severe conclusion, after the car ready for go kart, that the Impreza master is not strong enough to disengage the G50's fork (with a KEP heavy duty clutch). I need to change my master and apply whatever modifications at this far stage of the build to get something working.

I know a Tilton master and the Porsche 1987-1989 ones will work.

But what do you use? C05's master? Something else?

By any chance, do you have physical specs of your master?

The Subaru has 2xM7 or M8 holes about 2-3/4" apart.

Tnx

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote