-

09-01-2019, 02:14 PM

#561

Senior Member

Last edited by beeman; 09-02-2019 at 11:00 AM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

09-01-2019, 05:38 PM

#562

Senior Member

I'm going to try something...

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

09-01-2019, 07:35 PM

#563

Senior Member

I had hoped to do something like this originally, but the FFR hatch hinge and bracket were in the way...

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

09-03-2019, 07:06 AM

#564

Senior Member

Nice job on the brake booster, also enjoying reading through your build thread.

-

09-03-2019, 10:39 AM

#565

No issues on the Bel Ray. It costs me more than I sell it for by the time shipping etc. is calculated in. Your source is the cheapest I have seen. I will likely pick some up from them also.

-

09-04-2019, 10:23 AM

#566

Dave-

You are a freaking magician!! I really admire what you are doing, and how you are getting it done!

Your vision and execution are extraordinary, and I can't wait to see this thing done; but I am sure enjoying the build process, and the ride you are taking us on!!

Keep up the great work!!

Regards,

Steve

-

09-04-2019, 10:08 PM

#567

Senior Member

Dave

What year 350z roadster trunk hinge did you use to make your hinge? Looks good and really increases the hatch opening area.

-

09-05-2019, 07:21 AM

#568

Senior Member

Thanks Jkviper, Steve!

Originally Posted by

jamesfr58

Dave

What year 350z roadster trunk hinge did you use to make your hinge? Looks good and really increases the hatch opening area.

Any of the US spec 350z roadsters/convertible, I think 2004-2008. NOT the coupe/hatchback. It's not plug and play, but really pretty easy to do with some simple welding.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

09-05-2019, 12:53 PM

#569

I think Iíll steal that hinge idea.

update: I just bought a pair from eBay $18 shipped.

Last edited by HardRocker; 09-05-2019 at 01:10 PM.

-

09-05-2019, 01:05 PM

#570

Senior Member

-

09-06-2019, 10:49 AM

#571

Senior Member

Thanks Dave I have the hatch on now but still not happy with fit so will keep working on it and may change the hinges as the ones you made seem to work great.

-

09-16-2019, 10:04 PM

#572

Damn, you have all the answers for this monster!

At times I wish I knew all of these solutions before starting my build. It makes me want to redo my car over and over.

Your hatch contour is pretty much perfect with the roof line.

Did you modify anything, or was it matched "out of the box"?

Custom LCD Gauges , Data Loggers, Control Touch Screens

www.LCDdash.com \\ 647-522-9953 \\ Voice & Text

Proud new owner of GTM Gen 1., #105 - 08/27/11

LQ9 Powered, G96.00 6 speed transaxle

-

09-17-2019, 07:51 AM

#573

Senior Member

Originally Posted by

Procision-Auto

Damn, you have all the answers for this monster!

At times I wish I knew all of these solutions before starting my build. It makes me want to redo my car over and over.

Your hatch contour is pretty much perfect with the roof line.

Did you modify anything, or was it matched "out of the box"?

It didn't match perfectly out of the box. I think you are referring to this picture (I still have not made any adjustments after welding it in, may need to adjust slightly). The 350z hinges really control the position of the hatch leading edge. There is an adjustment screw built into the hinge as well that allows fine-tuning of the closed position. Before I installed the hinge, the driver's side leading edge of the hatch sat about 1/3" higher than it is in this picture. I placed a weight on that corner of the hatch to hold it symmetric to the passenger side of the hatch while I welded the mounting studs for the hinge to the GTM frame (hinge was already bolted to the hatch). Now it knows where to live in the closed position. The FFR hinges didn't have that control of position, too sloppy.

Last edited by beeman; 09-17-2019 at 09:13 AM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

09-19-2019, 01:14 PM

#574

With all the cv and axle work does anyone know a source for the c clips? They have been hard to find.

-

09-19-2019, 01:41 PM

#575

Originally Posted by

HardRocker

With all the cv and axle work does anyone know a source for the c clips? They have been hard to find.

Yeah, I had the same experience.....here is a thread I started on that:

https://thefactoryfiveforum.com/show...LE+SPRING+CLIP

I ended up finding some in a box on the shelf here, so never did try to order any or find them to purchase....

Shane Vacek

VRaptor SpeedWorks, LLC

www.vraptorspeedworks.com

Turn-key GTM, SL-C & Ultima GTR Built to Your Specs!

Offering a full line of GTM Upgrades and Custom Parts

-

09-21-2019, 02:29 PM

#576

Thanks Shane. That 22727024 part number did the trick.

-

11-05-2019, 11:55 AM

#577

Senior Member

-

11-05-2019, 12:02 PM

#578

Senior Member

-

11-05-2019, 07:16 PM

#579

Senior Member

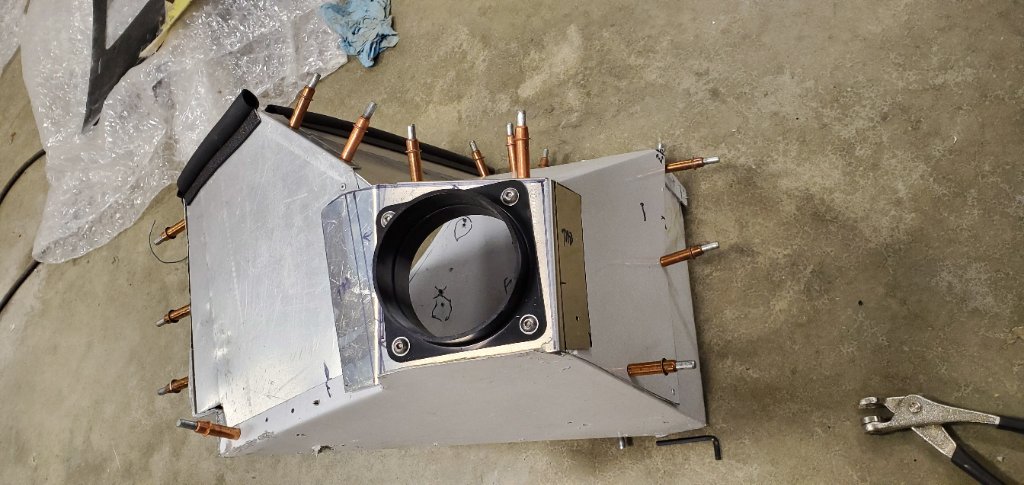

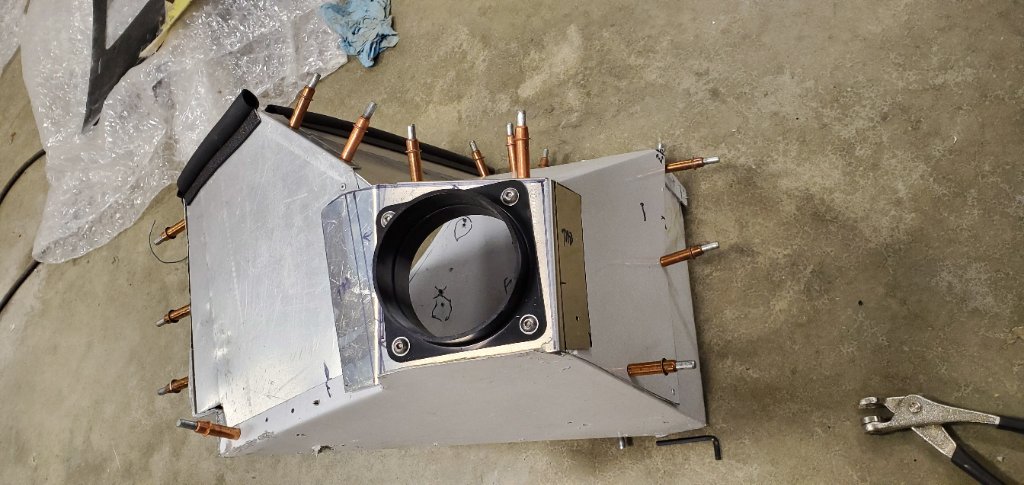

Just about finished up the airbox. Not trying to win any beauty pageants since the outside will be covered with heat shielding.

Air filter is accessible, the red portion of the airbox will be held in place by screws/rivnuts.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

11-29-2019, 08:20 PM

#580

Senior Member

-

11-29-2019, 08:25 PM

#581

Senior Member

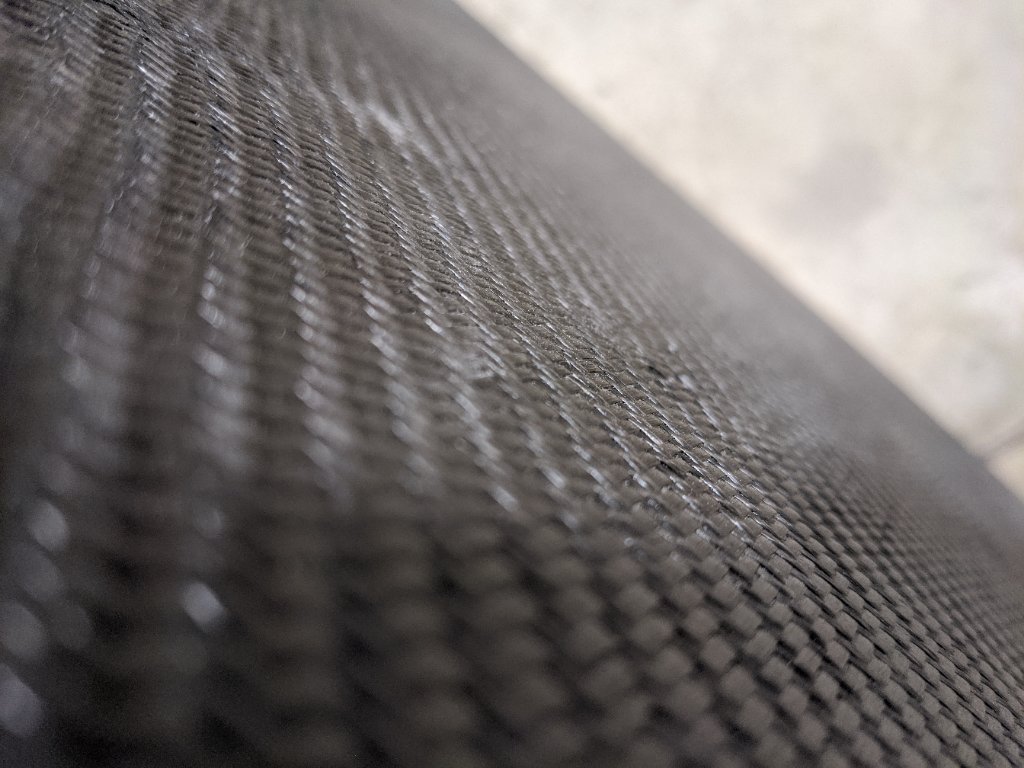

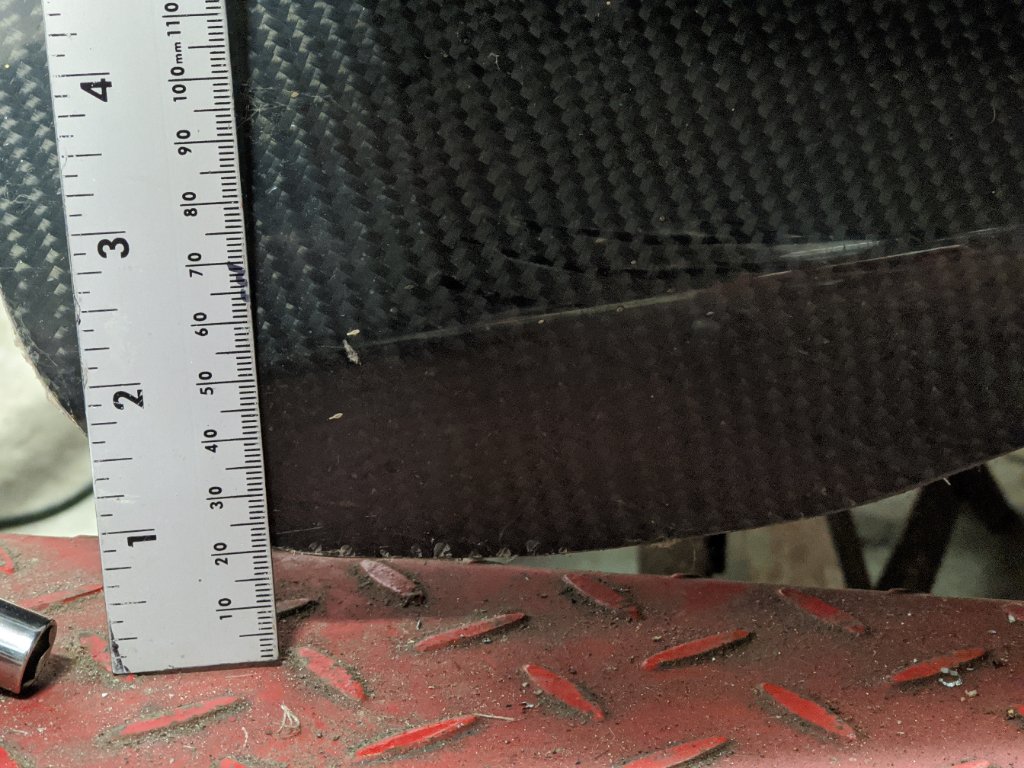

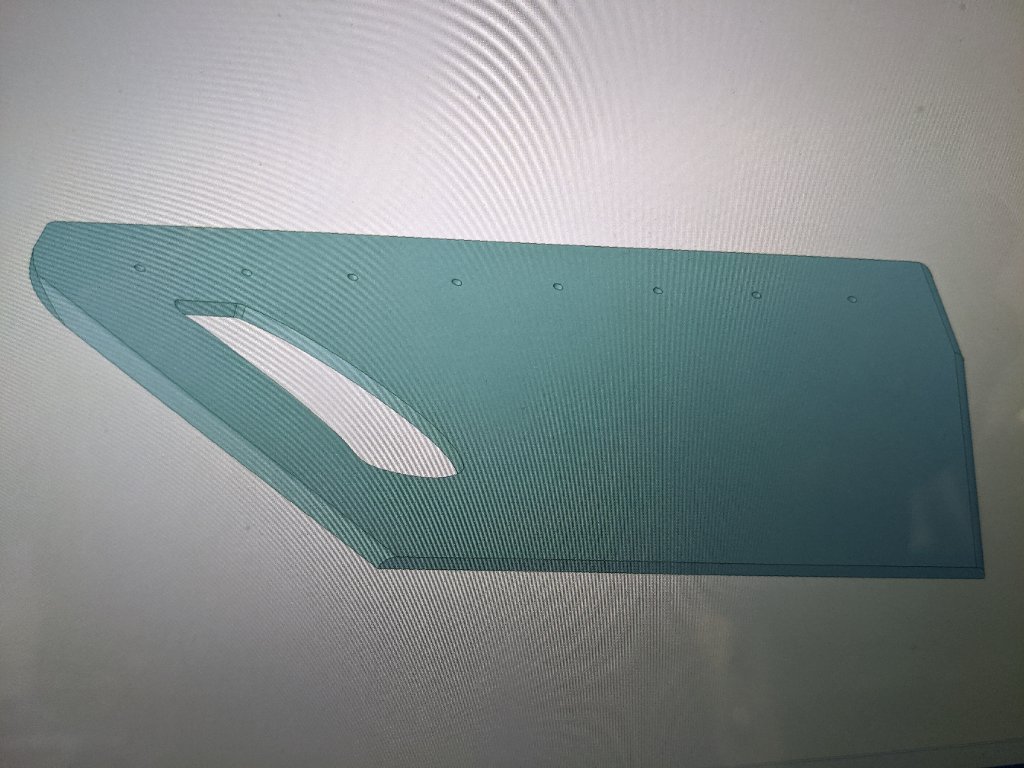

Finishing up the spoiler...

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

11-30-2019, 11:00 AM

#582

Senior Member

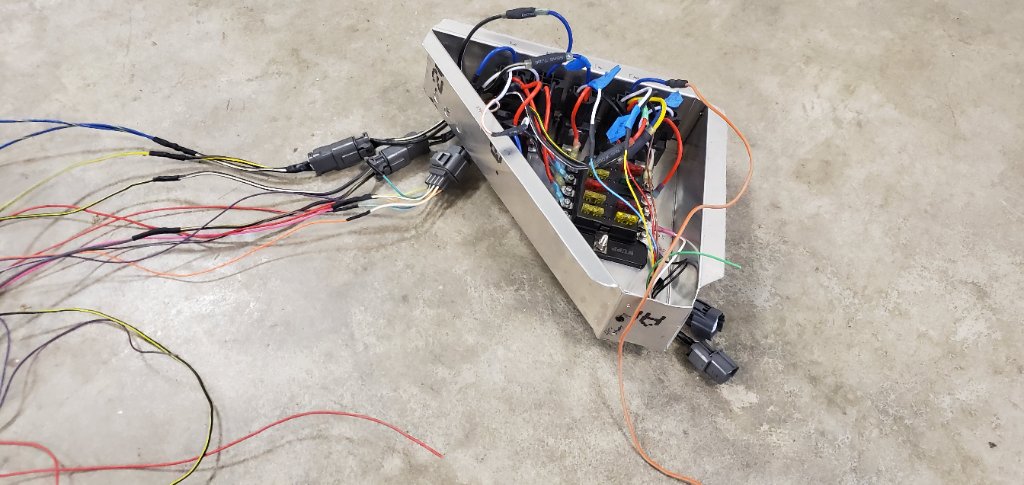

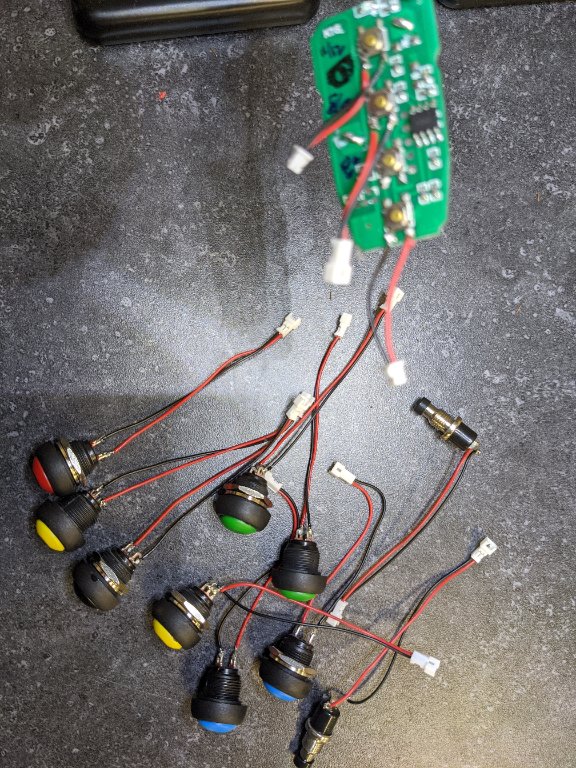

Even back in '94 Honda was using variable resistors to control lighting, wipers, etc. So I'm having to tear switches apart and jump the internals to dumb them down a little.

I wired up the turn signals to a standard flasher relay and FYI for you guys planning on running LED lights on the corners, the LEDs don't draw enough current to make the flasher relay even work. Ordered some flasher relays designed for the low draw of LEDs:

https://www.amazon.com/dp/B011BTMDQM..._1.O4DbN6JQ5QG

Last edited by beeman; 11-30-2019 at 11:03 AM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-02-2019, 01:32 PM

#583

Originally Posted by

beeman

I wired up the turn signals to a standard flasher relay and FYI for you guys planning on running LED lights on the corners, the LEDs don't draw enough current to make the flasher relay even work. Ordered some flasher relays designed for the low draw of LEDs:

All you need to do is put a resistor across the LED leads to increase the draw when in use. The LED specific flashers are the official way to do it, but the resistors are the cheap and easy way to do it.

-

12-03-2019, 08:30 AM

#584

Beeman,

here is a link to the load resistors that I used, for the led turn signal lights that were supplied by FFR.

https://www.superbrightleds.com/more...g-fix/190/831/

Steve

-

12-04-2019, 06:29 AM

#585

Senior Member

Originally Posted by

beeman

Dave,

What are your thoughts on adjusting brake bias? You and I have a similar setup to our mid engine kits and I am not sure if I will need to add a proportioning valve to either the front or the rear brakes or both to dial it in. Curious what you are thinking.

Thanks,

Joel

-

12-04-2019, 04:48 PM

#586

Senior Member

Thanks Mike and Steve.

Dave,

What are your thoughts on adjusting brake bias? You and I have a similar setup to our mid engine kits and I am not sure if I will need to add a proportioning valve to either the front or the rear brakes or both to dial it in. Curious what you are thinking.

Thanks,

Joel

Joel, are you running ABS? I'm running the OEM C5 ABS/EBCM so I'm not so concerned about front or rear lock-up, but there still may be some imbalance under track conditions. I looked through some of the C5 forums and usually guys are changing calipers to get more braking from the rear. Some of the C5 Track guys have ripped out the ABS and went with a Tilton/Wilwood setup. I don't think a variable proportioning valve is a great option in my situation as it would probably screw with the EBCM. I'm wanting the best option for street + track. Track only, I would probably ditch the ABS and booster entirely.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

12-04-2019, 05:15 PM

#587

Senior Member

No ABS, no track and the stock Gen V Camaro dual Master Cylinder(1” bore) with Gen 5 Camaro SS calipers. The stock Tilton master cylinders are 3/4” front and 7/8” rear so if my math is correct this setup sends 16% more pressure to the rear calipers. So my thinking is to maybe put the proportion valve on the front brakes and that way I could create similar balance.

I have’t put much thought beyond that, but thought I’d ask since we are following similar paths.

-

12-04-2019, 06:05 PM

#588

Originally Posted by

Jkviper

No ABS, no track and the stock Gen V Camaro dual Master Cylinder(1” bore) with Gen 5 Camaro SS calipers. The stock Tilton master cylinders are 3/4” front and 7/8” rear so if my math is correct this setup sends 16% more pressure to the rear calipers. So my thinking is to maybe put the proportion valve on the front brakes and that way I could create similar balance.

I have’t put much thought beyond that, but thought I’d ask since we are following similar paths.

With the larger MC on the rear brakes, that should make less pressure than the fronts......more fluid flow, less pressure. You would have to go to smaller MC size to increase pressure.....

Shane Vacek

VRaptor SpeedWorks, LLC

www.vraptorspeedworks.com

Turn-key GTM, SL-C & Ultima GTR Built to Your Specs!

Offering a full line of GTM Upgrades and Custom Parts

-

12-04-2019, 10:51 PM

#589

Senior Member

Originally Posted by

VRaptor SpeedWorks, LLC

With the larger MC on the rear brakes, that should make less pressure than the fronts......more fluid flow, less pressure. You would have to go to smaller MC size to increase pressure.....

Thanks so much Shane for adding your input. i’m Glad I have it backward, now it makes more sense with what I would need to do to get good brake balance. Dave, didn’t mean to hijack your thread and appreciate your feedback as well.

-

12-06-2019, 03:30 PM

#590

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-18-2019, 10:18 AM

#591

Senior Member

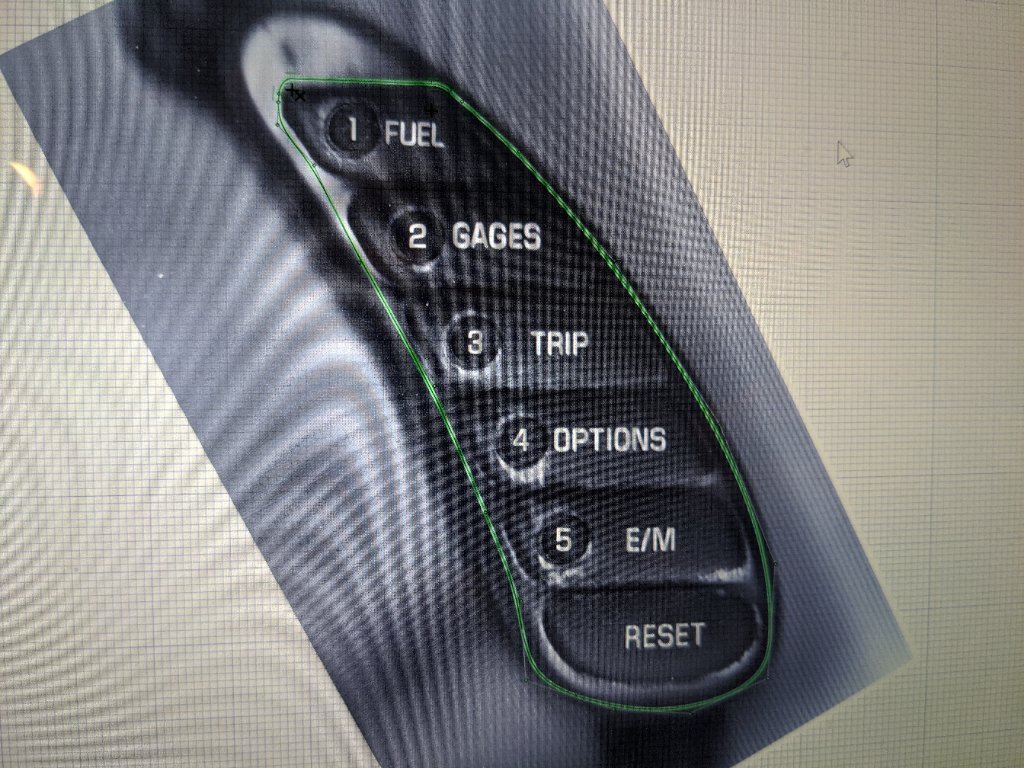

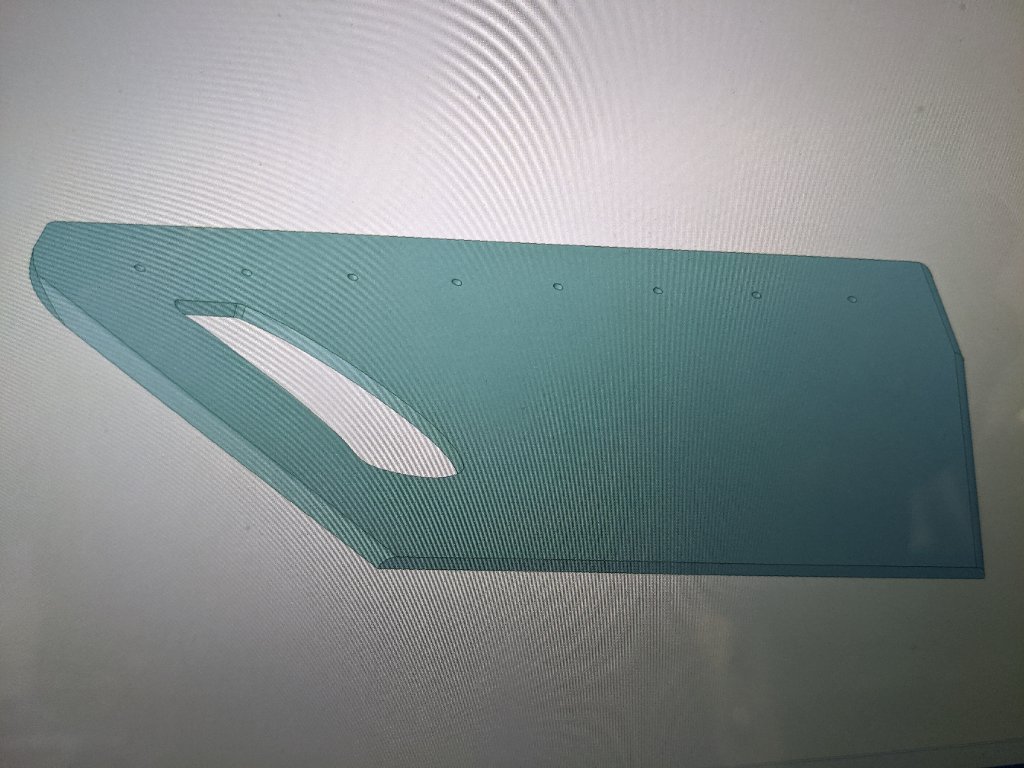

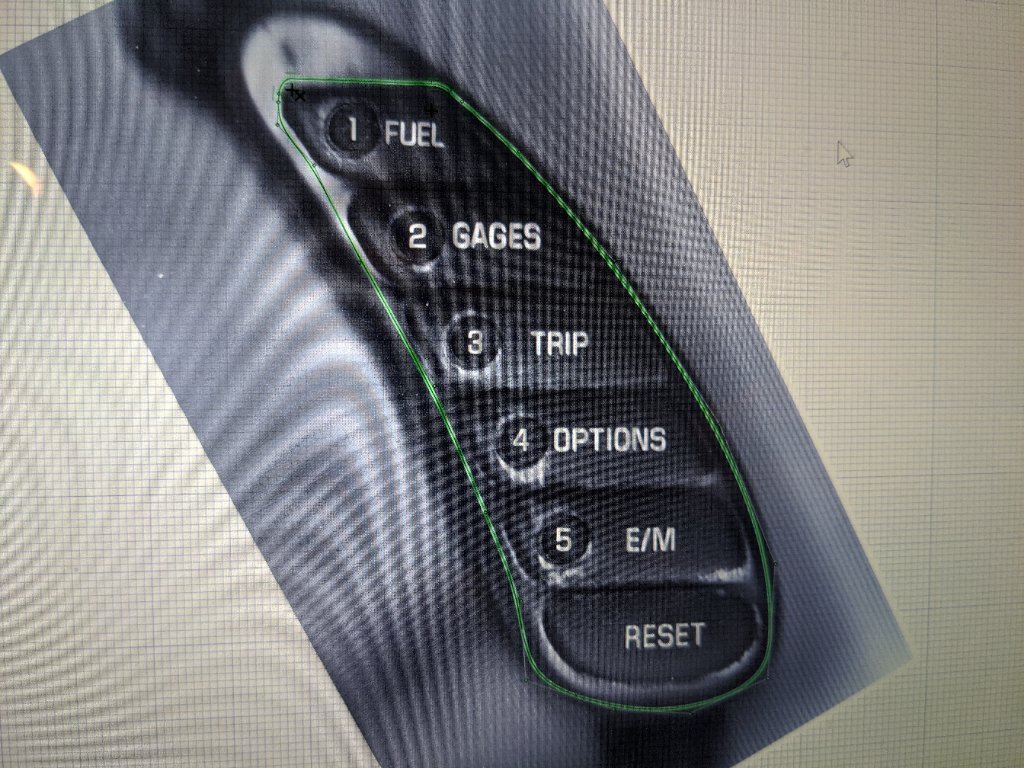

Continuing to mock up the console... I wouldn't dare build a C5 based kit without a manly DIC!

Last edited by beeman; 12-18-2019 at 11:04 AM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-18-2019, 10:01 PM

#592

Member

Originally Posted by

beeman

Thanks Mike and Steve.

Joel, are you running ABS? I'm running the OEM C5 ABS/EBCM so I'm not so concerned about front or rear lock-up, but there still may be some imbalance under track conditions. I looked through some of the C5 forums and usually guys are changing calipers to get more braking from the rear. Some of the C5 Track guys have ripped out the ABS and went with a Tilton/Wilwood setup. I don't think a variable proportioning valve is a great option in my situation as it would probably screw with the EBCM. I'm wanting the best option for street + track. Track only, I would probably ditch the ABS and booster entirely.

If you are considering tuning the GTM for the track

The proportioning setup from willwood is required.

I has stop tech custom build the calipers to match the weight bias and traction of the GTM. Even so the ability to adjust the bias really changes the turn in.

On the street it doesnít matter at all. The GTM has so much extra braking capacity itís silly.

On the track some form of bias adjustment is a must have.

The C5 although using the same components doesnít drive anything like a GTM on the track. Itís apples and pineapples.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

12-18-2019, 10:04 PM

#593

Member

Originally Posted by

beeman

Nice job man. Are you milling or printing those components?

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

12-18-2019, 10:32 PM

#594

Senior Member

Originally Posted by

kabacj

Nice job man. Are you milling or printing those components?

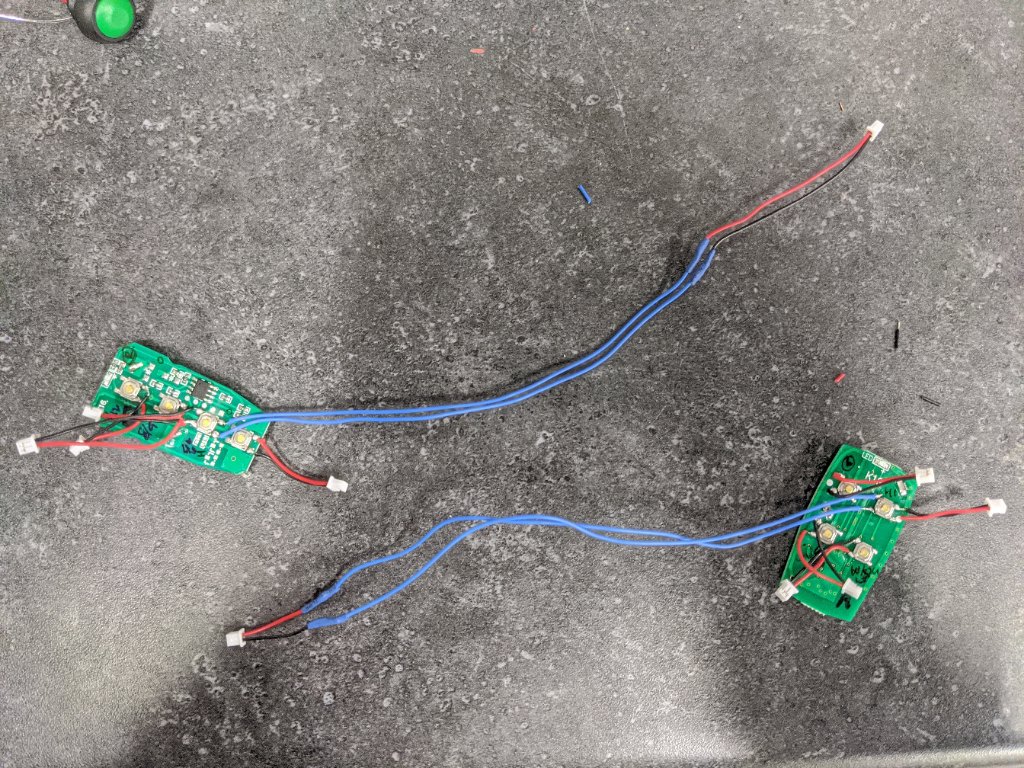

3D printing. Prototypes in PLA, final components will be carbon fiber reinforced nylon. How's your track car? Any updates?

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

12-20-2019, 07:25 AM

#595

Member

Originally Posted by

beeman

3D printing. Prototypes in PLA, final components will be carbon fiber reinforced nylon. How's your track car? Any updates?

Very cool. Yeah Iíve been busy updating my capabilities in the shop for the next phase of development. I need some robots to help me get the job done. Updates are coming soon.

XTF #2

build start date June 19 2023

GTM # 344

Build Start December 2010

First track day April 2013

-

12-20-2019, 09:10 AM

#596

The redneck setup looks pretty sharp to me!!! Nice work

-

01-12-2020, 01:41 PM

#597

Senior Member

-

01-12-2020, 08:15 PM

#598

Apparently not enough space to hamper your build LOL. Maybe one day I’ll have a shop big enough to fit my build(s) and and trampoline

-

01-16-2020, 04:56 PM

#599

Senior Member

-

01-16-2020, 07:40 PM

#600

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

RR46

RR46 liked this post

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote