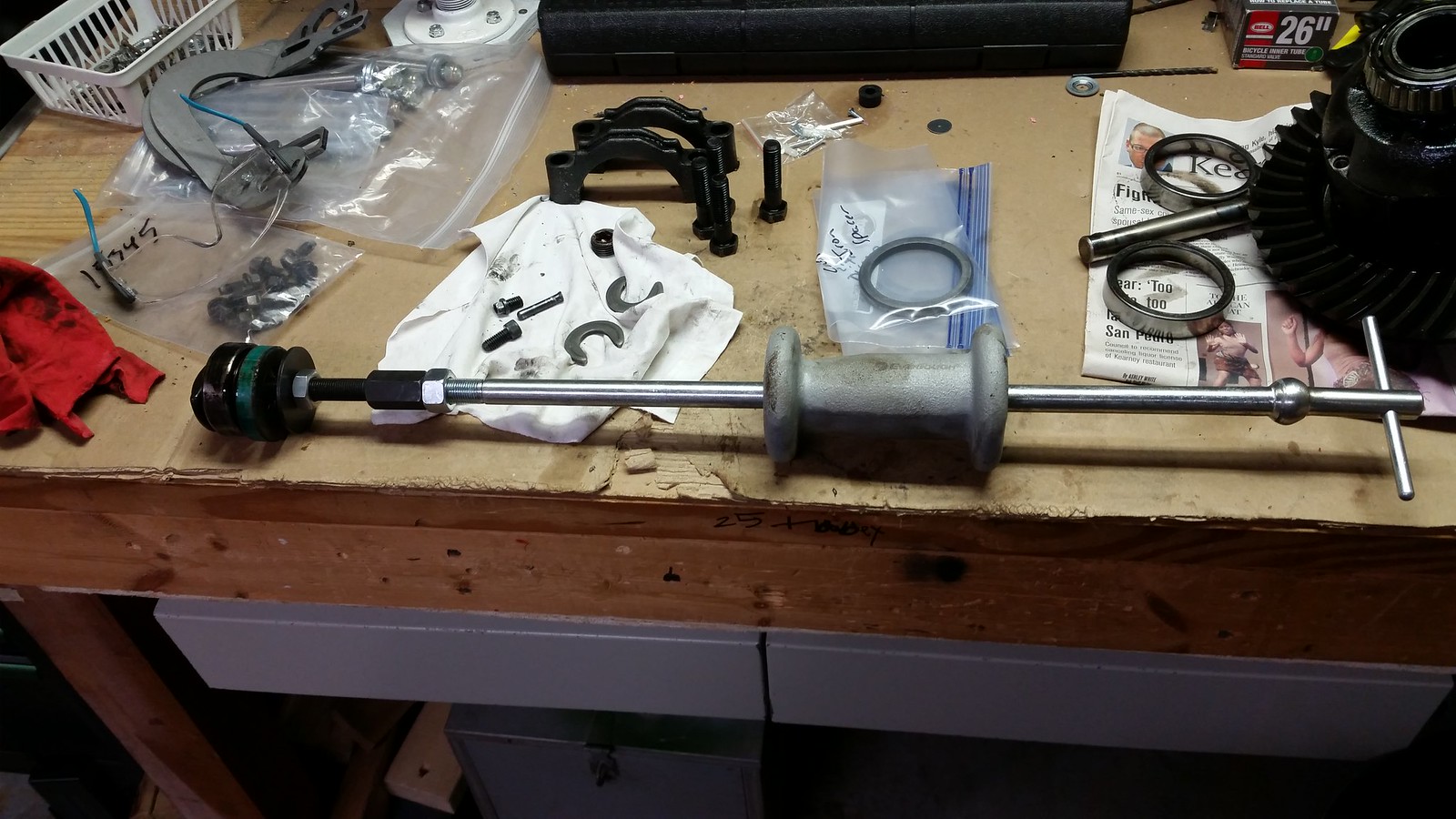

For the axle, I decided to go with the 3 link straight axle. I would prefer the IRS, but I felt this was an area that I could save a bit of money and still end up with good performance. Obviously, I'll be giving up some of the smooth ride characteristics of the IRS, but I need to keep the budget in check some how and I'm willing to sacrifice. I gave myself the goal of buying and rebuilding the axle for a total of $1000. After looking into parts, I decided for that price, I can get a used axle, gut it and replace all the internal parts with new parts, plus have enough left over to pay a professional to do the more complicated setup procedures if I get in over my head (or lack the tools). We'll see how this works out.

Since this is going to be the only donor part in my roadster, I started on the quest to find a suitable axle long before I ordered my kit. I did some reading on the forum and general question asking. See my old post here. I learned that the axle for the Fox body GT Mustangs ('87 to '93), that Factory Five designed their kit around, is the ideal size at 59.25" flange to flange. I also learned that the axle housings for the '94 to '98 Mustang GTs are the exact same length, however the axle shafts in those years are roughly .75" wider per side. Since I was planning on replacing all the internals of the axle, the shaft lengths didn't concern me and any housing from 87' to 98' would work. If you are going to rebuild an axle and are thinking of using the stock internal parts, keep in mind that the fox body 'stangs had 4 lug axle shafts, so they would need to be replaced if you are going to use 5 lug rims. Basically, you'll be replacing the axle shafts in any axle from '87 to '98 no matter what, unless you are using 4 lug rims or wheels with a custom offset.

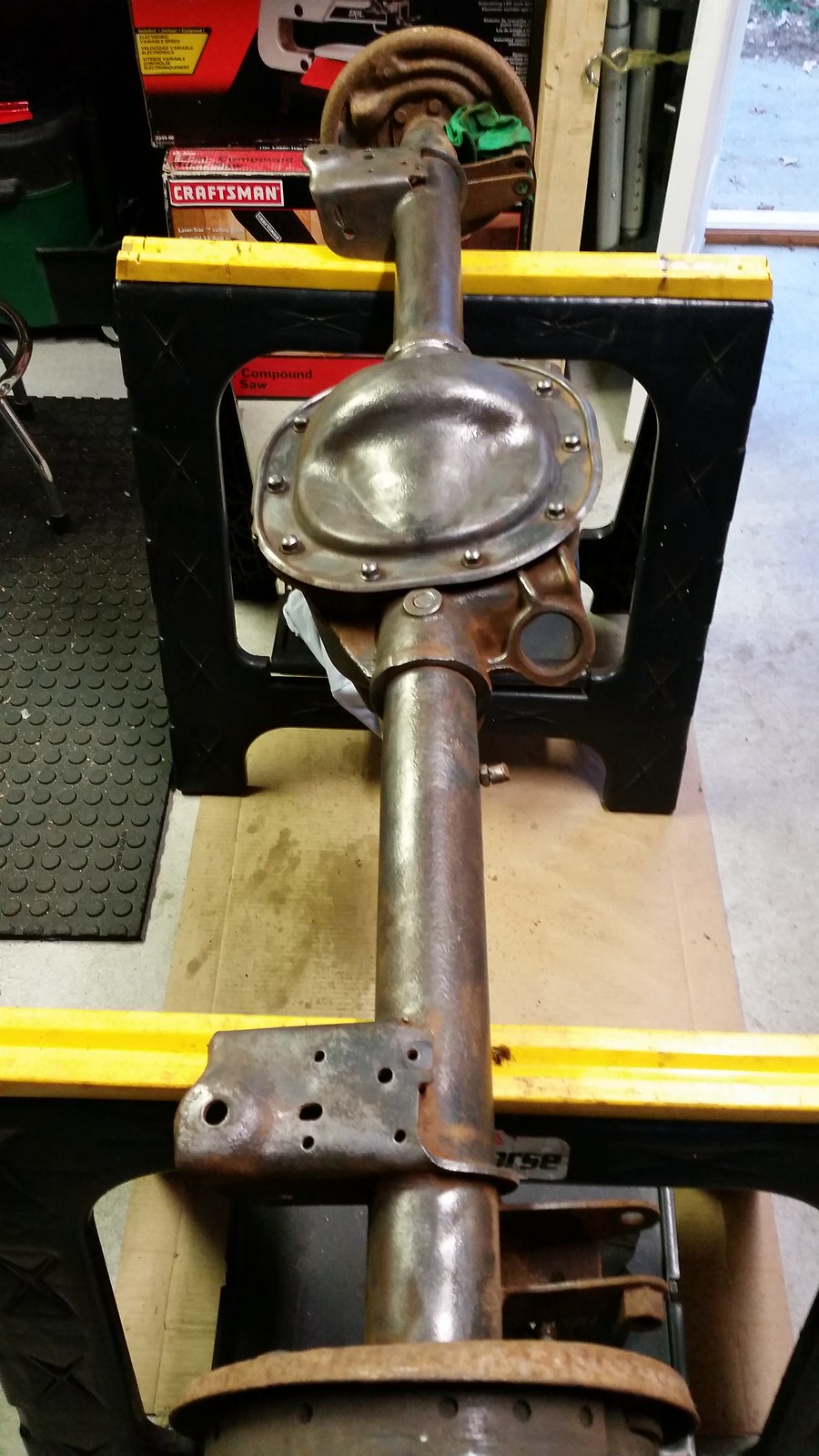

I called the local auto salvage yards, but didn't turn up much. I put a post on a local Facebook buy/sell/trade group and located an axle a few hours from my place that came out of a '89 Mustang GT. I picked it up the following weekend and ended up scoring the whole assembly for $150.

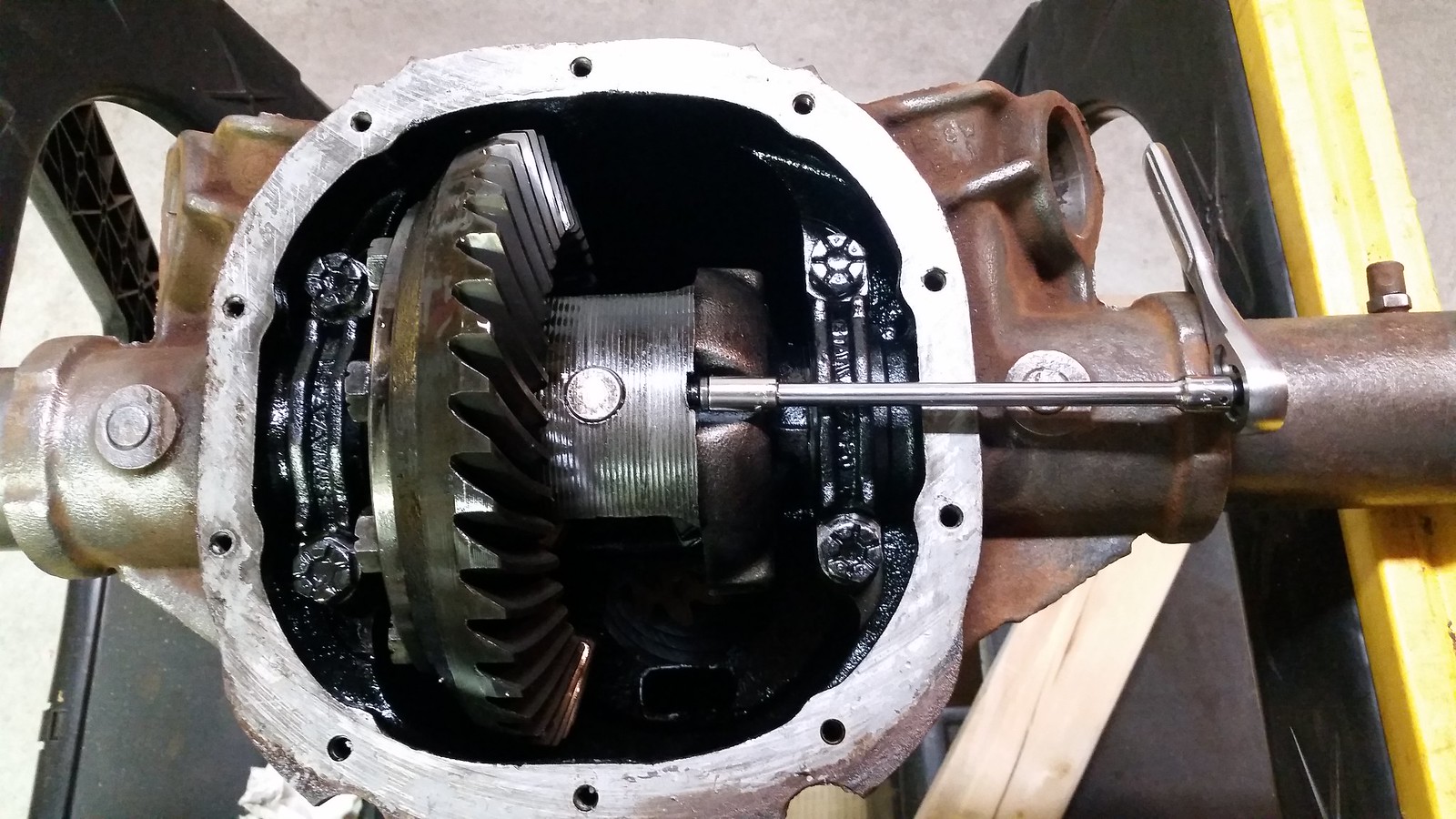

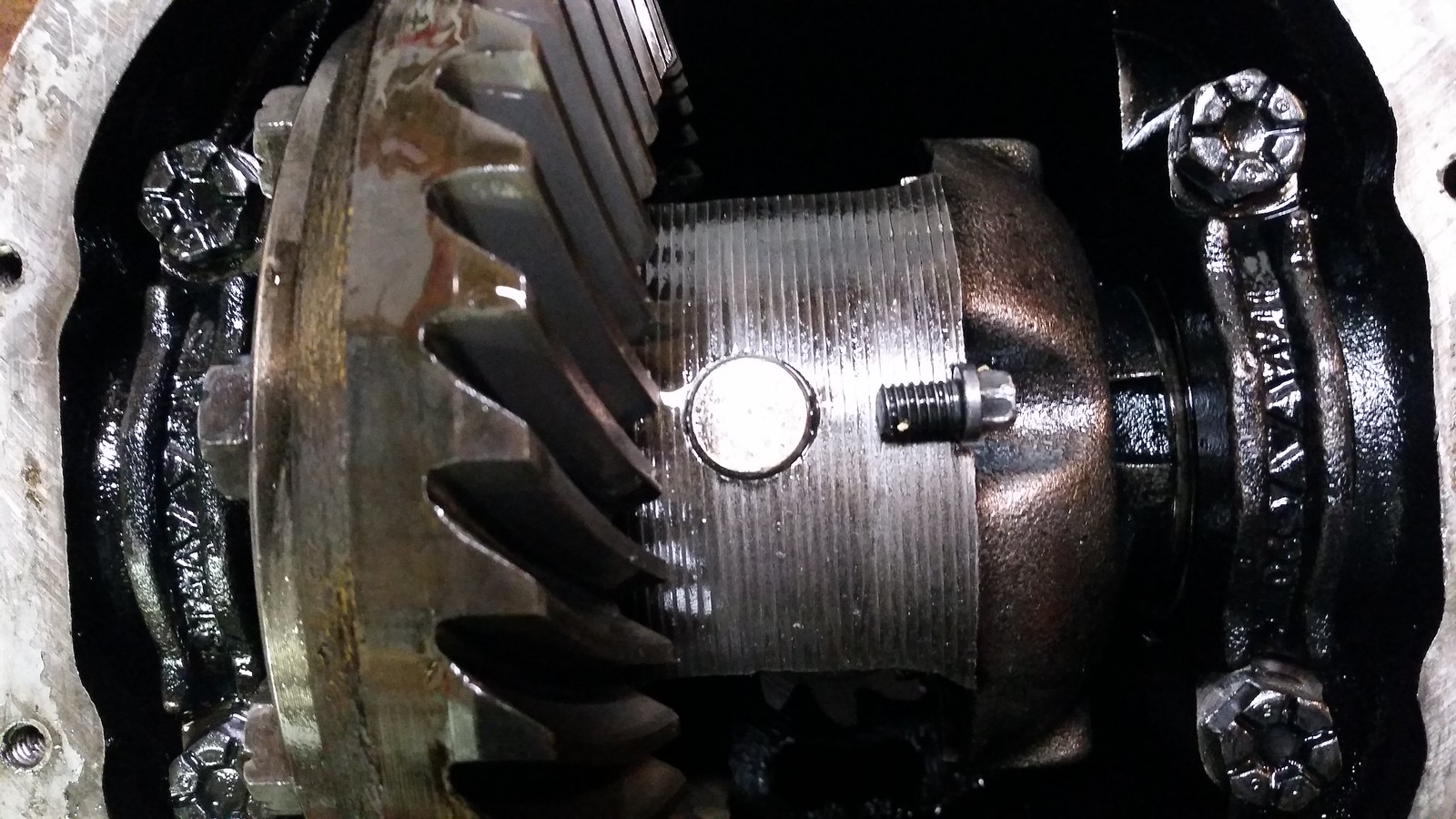

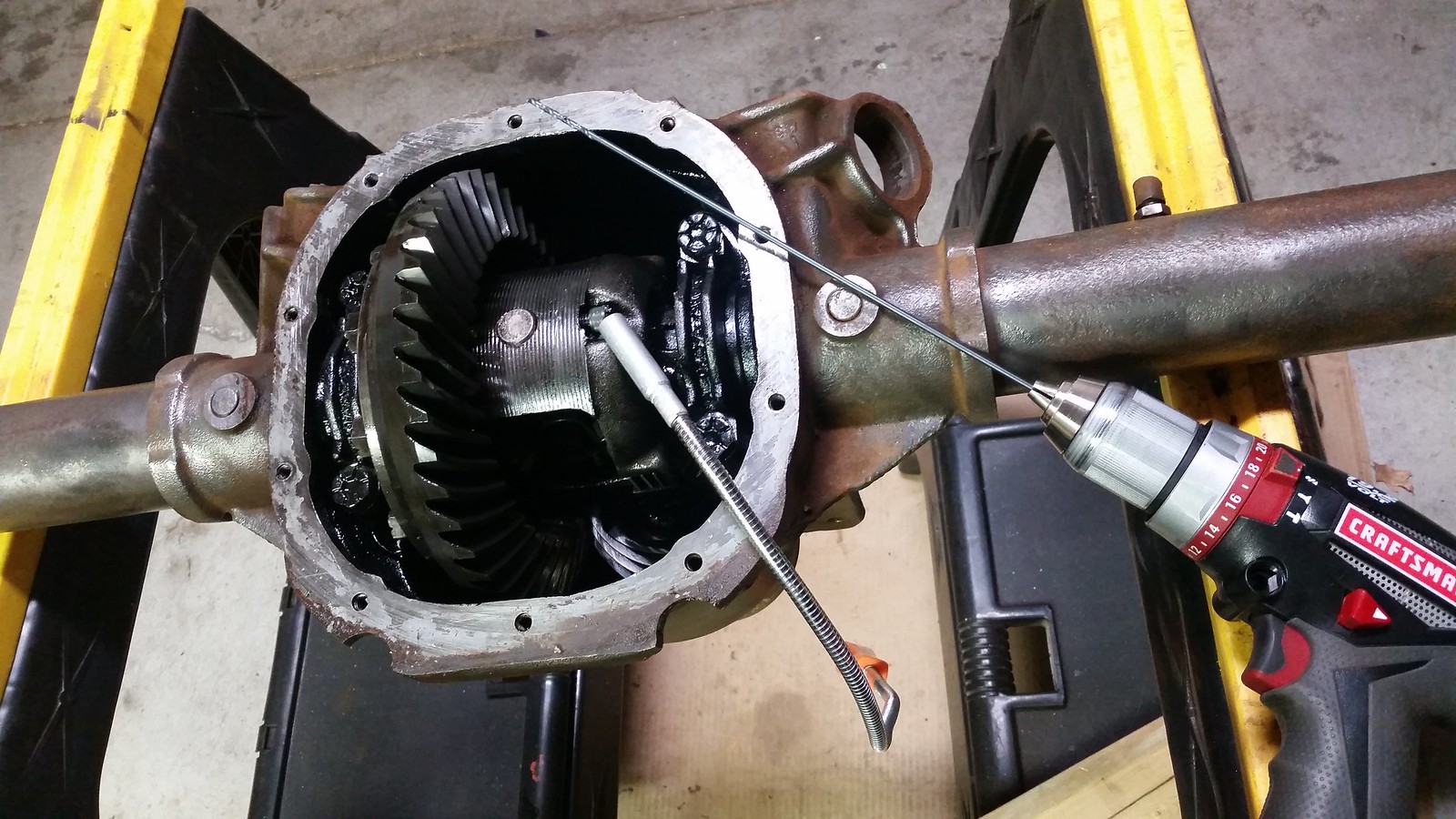

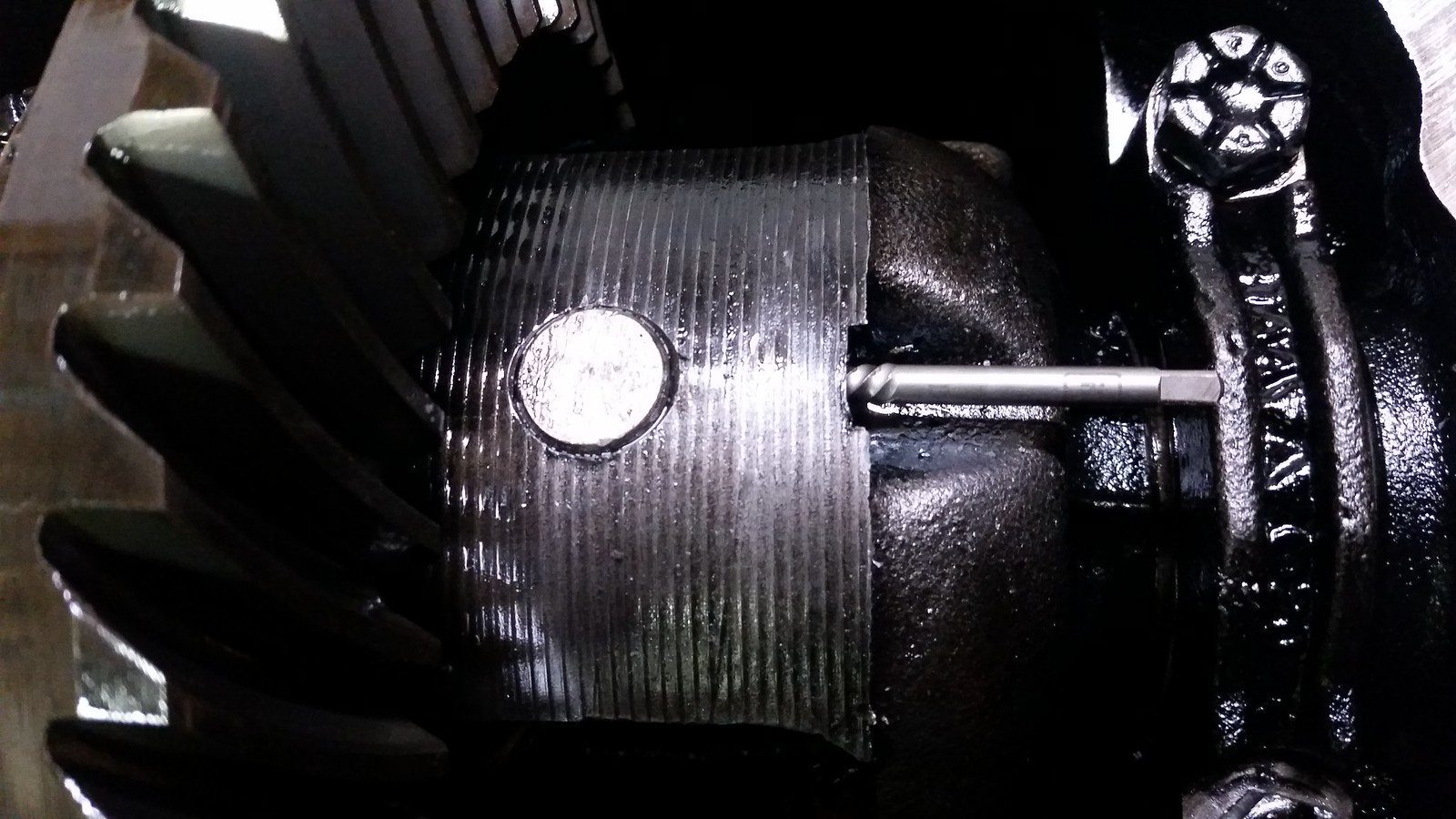

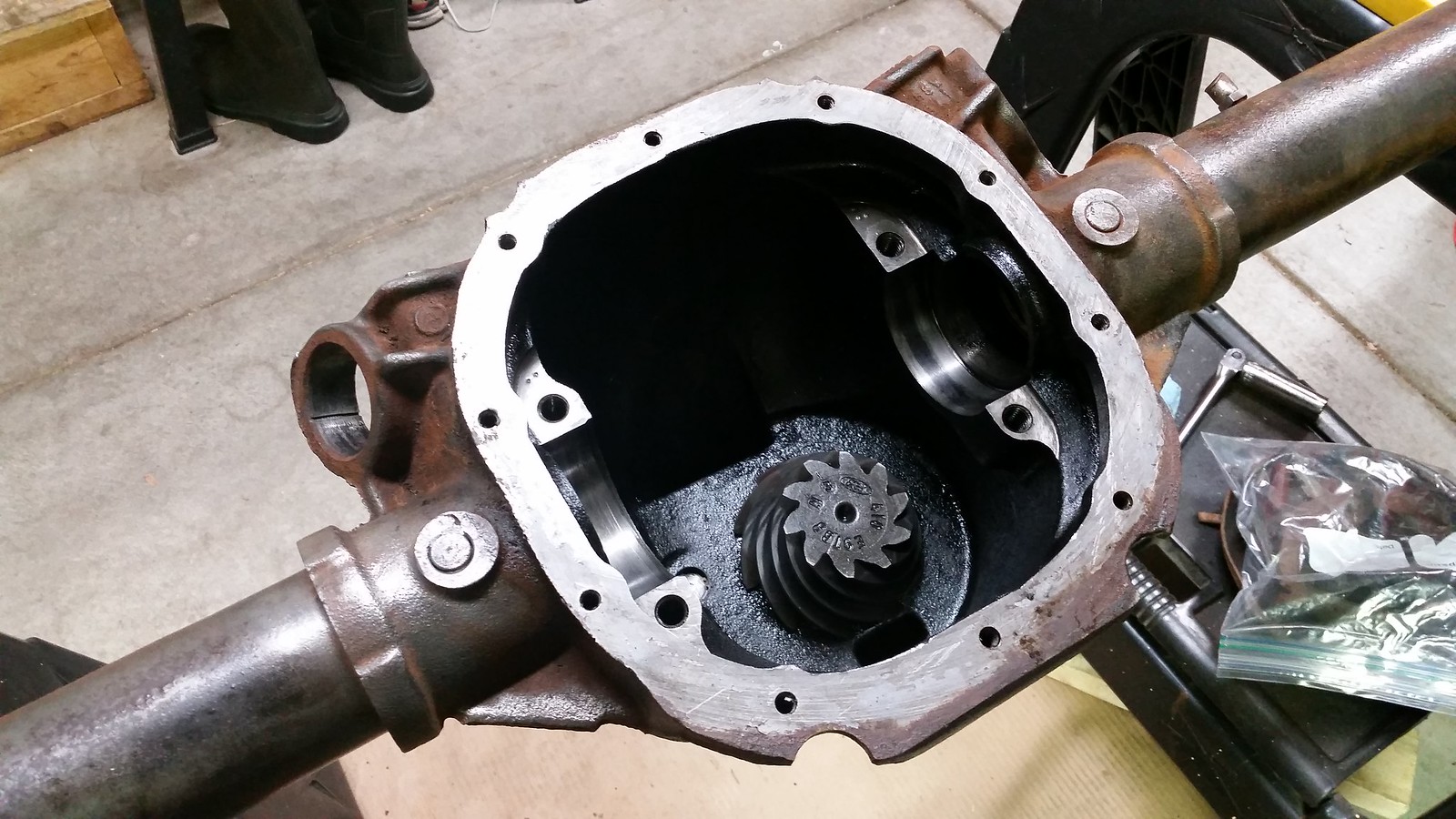

Here's what it looked like when we brought it home. It's not the prettiest thing it the world, but I think it'll work. With a little hard work it will look better than new. It's complete with rusty brake lines, leaky quad shocks, drum brakes, trac lok diff, and the rest of the works.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

Thanks!

Thanks!

. Its very clear and you'll have a good guide for getting things dialed in. Now you've got me motivated to see if I can keep pace - I've gotta go back up front and get the steering in (as well as pedal box) to stay even near you!

. Its very clear and you'll have a good guide for getting things dialed in. Now you've got me motivated to see if I can keep pace - I've gotta go back up front and get the steering in (as well as pedal box) to stay even near you!