Hi Guys,

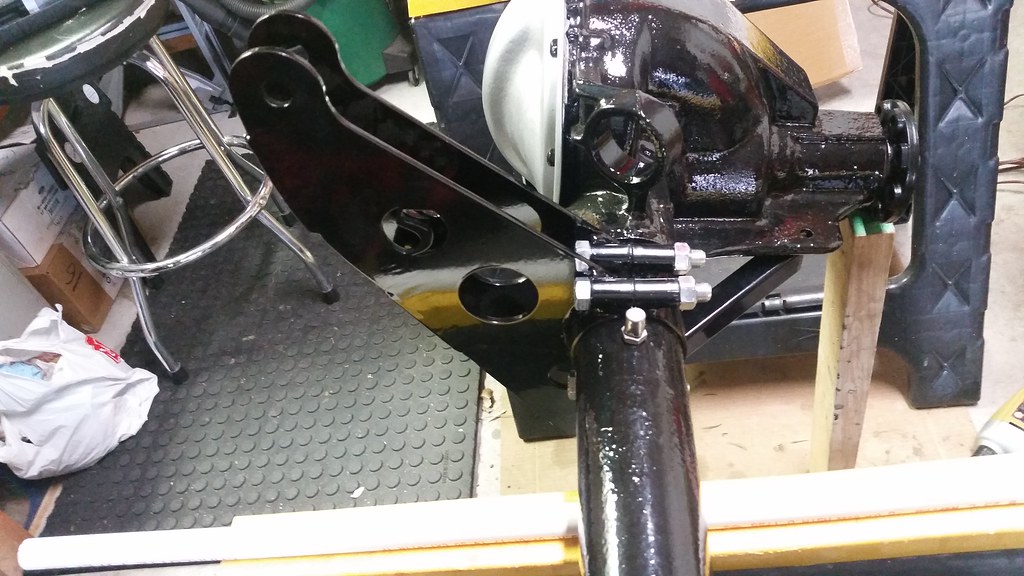

I did a test fit of my banana bracket to my axle this weekend. When fitting it up by hand, the ID of the bracket does not seat up against the axle tube completely. It is too tight. It is probably about .25" short of going on completely. Is this something that normally requires some grinding to make it fit? Or will it go on by inserting the bolts and tightening them down? The smaller clam shell portion slips over the axle easily. I assume these parts shouldn't be too loose. FYI...I do have a VPM brace I am planning to use.

Thanks!

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote