-

Senior Member

Hydraulic clutch

Have not yet received my MKIV. However, in studying the forums I have an interest in hydraulic Clutch. I need to know what is involved in making this change. Also where to buy the parts. Is this a major change?

Thanks for the help.

-

Senior Member

It's not a major change, but you would need to spend more money and it is a bit more complex to set up. You will have to add a master cylinder to your clutch pedal and the slave will activate the clutch release bearing, and you will need another reservoir and run additional hydraulic hard lines . You can either go with an external slave that pushes against the existing clutch fork or use an internal "hydraulic release bearing" that goes around the input shaft of your transmission. I am going with the later from Tilton:

http://tiltonracing.com/product/6000...ease-bearings/

_1486_detail.jpg)

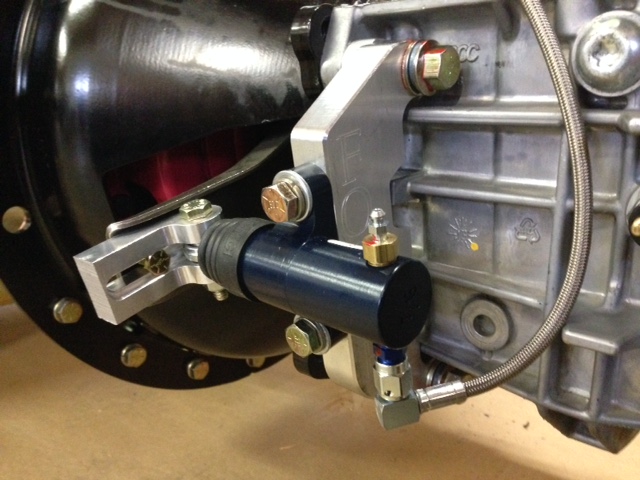

Here is a pic of the type that pushes on the clutch fork, essentially replacing the cable but utilizing a standard release bearing internally:

Last edited by shark92651; 03-29-2018 at 04:03 PM.

-

Senior Member

Does this change involve modification of frame. I prefer not to have to do any welding. Also, what is the advantage if any? And I would probably appreciate a guess as to how much more expense?

Thanks again I appreciate you help.

-

The forte kit, pictured second costs $425 plus a resivoir and shipping last I heard. It is a very popular option around these parts, and that price may vary based on your specific needs and configuration. Mike would best be able to answer specifics if you gave him a call.

Price to set up with a release bearing I do not know.

-

Senior Member

Originally Posted by

John T

Does this change involve modification of frame. I prefer not to have to do any welding. Also, what is the advantage if any? And I would probably appreciate a guess as to how much more expense?

Thanks again I appreciate you help.

shark92651 pretty much covered it showing the available options. With one big caveat. Changing to a hydraulic clutch is a pretty easy mod if you're Mk4 is built with the Wilwood pedal box. No welding required. Just bring money.

The Wilwood pedal box is actually designed to use a hydraulic clutch, so it's a simple bolt in of the additional master cylinder on that side. Factory Five supplies some custom parts they designed to convert it to a cable driven setup, which you wouldn't use. The external slave setup pictured is from Mike Forte, and is a common setup when going hydraulic. He has various versions depending on the transmission you're planning to use. You can call him for details and price for your specific configuration. I've installed a couple of these and they're pretty straightforward. The internal hydraulic throw-out bearing isn't nearly as common for these builds, although quite common in the industry. The current Mustang uses one, for example. The concern with the internal throw-out bearing is that if it fails or needs to be serviced, the transmission needs to be removed. Same as replacing the clutch. For a Roadster, it's possible but not easy. Some just pull the whole engine/transmission assembly. I'm going to try that same Tilton internal hydraulic throw-out bearing on my current Gen 3 Coupe build. It's simpler and cheaper than the external slave setup and the Tilton part is supposed to be very high quality. But the new Coupe chassis would make getting the transmission in/out a little easier, even though I really hope that's not necessary. To say the least.

If you're planning to do a Mustang pedal box, not so easy to add a hydraulic clutch. They're only made for cable drive setups. As I understand, there are aftermarket kits and ways to install, but I personally have no experience with them so can't offer anything else.

Clutch cable over hydraulic is often discussed, but doesn't always have a clear-cut answer. The current Factory Five adaptation (compared to the much less successful previous version), a genuine Ford branded cable (important, there are differences), and proper routing of the cable that is direct and away from heat sources (like headers) works fine. A hydraulic setup solves any issues with routing the cable, and in theory should have less mechanical drag and be smoother to operate and with potentially less effort. But there are other variables, especially which clutch you choose, so it's not easy to cite comparisons.

Last edited by edwardb; 03-30-2018 at 06:03 AM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Curmudgeon

If you are looking for pros-cons, cable is used by OE because it's cheaper. Hydraulic is more reliable, offers variable pedal force (by altering master size), offers better feel due to reduced operating friction.

MKII "Little Boy". 432CI all aluminum Windsor. .699 solid roller, DA Koni shocks, aluminum IRS, Straight cut dog ring T-5, 13" four piston Brembos, Bogart wheels. BOOM!

-

Senior Member

Originally Posted by

edwardb

shark92651 pretty much covered it showing the available options. With one big caveat. Changing to a hydraulic clutch is a pretty easy mod if you're Mk4 is built with the

Wilwood pedal box. No welding required. Just bring money.

The Wilwood pedal box is actually designed to use a hydraulic clutch, so it's a simple bolt in of the additional master cylinder on that side. Factory Five supplies some custom parts they designed to convert it to a cable driven setup, which you wouldn't use. The external slave setup pictured is from Mike Forte, and is a common setup when going hydraulic. He has various versions depending on the transmission you're planning to use. You can call him for details and price for your specific configuration. I've installed a couple of these and they're pretty straightforward. The internal hydraulic throw-out bearing isn't nearly as common for these builds, although quite common in the industry. The current Mustang uses one, for example. The concern with the internal throw-out bearing is that if it fails or needs to be serviced, the transmission needs to be removed. Same as replacing the clutch. For a Roadster, it's possible but not easy. Some just pull the whole engine/transmission assembly. I'm going to try that same Tilton internal hydraulic throw-out bearing on my current Gen 3 Coupe build. It's simpler and cheaper than the external slave setup and the Tilton part is supposed to be very high quality. But the new Coupe chassis would make getting the transmission in/out a little easier, even though I really hope that's not necessary. To say the least.

If you're planning to do a Mustang pedal box, not so easy to add a hydraulic clutch. They're only made for cable drive setups. As I understand, there are aftermarket kits and ways to install, but I personally have no experience with them so can't offer anything else.

Clutch cable over hydraulic is often discussed, but doesn't always have a clear-cut answer. The current Factory Five adaptation (compared to the much less successful previous version), a genuine Ford branded cable (important, there are differences), and proper routing of the cable that is direct and away from heat sources (like headers) works fine. A hydraulic setup solves any issues with routing the cable, and in theory should have less mechanical drag and be smoother to operate and with potentially less effort. But there are other variables, especially which clutch you choose, so it's not easy to cite comparisons.

Thanks, as you can tell I am a novice at this build. You input is very helpful.

-

Senior Member

Originally Posted by

mikeinatlanta

If you are looking for pros-cons, cable is used by OE because it's cheaper. Hydraulic is more reliable, offers variable pedal force (by altering master size), offers better feel due to reduced operating friction.

And thanks to you. All of the information you guys give me will help me make up my mind. I assume that this decision should be made early in the build.

-

Senior Member

Originally Posted by

John T

And thanks to you. All of the information you guys give me will help me make up my mind. I assume that this decision should be made early in the build.

Also, as you increase HP, or build a more powerful motor, or what have you... more pedal pressure (with a cable clutch) is translated to the driver clutch pedal. Not so with the hydraulic route. Pedal pressure can be mitigated to feel stock while running 600+HP. Huge advantage when selling, too.

For instance: I'm running a BOSS (Coyote Variant) making 444HP. I'm running a McCleod twin disc clutch. Hydraulic throw out. So I will feel even less pressure because the twin plate set up doubles my clutch surface area and takes even more pressure off the pedal. It will drive as light as a stock BOSS and allow me to run well over 600 crank, eventually. Cables also stretch over time, cause engagement problems, but it takes a while.

Lastly, in comparing pricing: Anything DONE RIGHT, isn't cheap. Go the best route, it pays in the end.

A similar cable set up will be a little less expensive, but you'll have one well trained left calf with decent HP numbers.

Hope this all helps.

Gen3 Coupe - SOLD Arrival:

6/21/18 SOLD: 4/12/2019

Current Vehicle: 2014 SRT Viper (modded to the moon), 2022 TRX, 2014 RS6, E46 LS3 M3

Current Projects: Superlite/RCR GTR ***FOR SALE***

@madd_wrapps on IG or

www.maddwrapps.com

-

Senior Member

Originally Posted by

TheBabyBadger

Also, as you increase HP, or build a more powerful motor, or what have you... more pedal pressure (with a cable clutch) is translated to the driver clutch pedal. Not so with the hydraulic route. Pedal pressure can be mitigated to feel stock while running 600+HP. Huge advantage when selling, too.

For instance: I'm running a BOSS (Coyote Variant) making 444HP. I'm running a McCleod twin disc clutch. Hydraulic throw out. So I will feel even less pressure because the twin plate set up doubles my clutch surface area and takes even more pressure off the pedal. It will drive as light as a stock BOSS and allow me to run well over 600 crank, eventually. Cables also stretch over time, cause engagement problems, but it takes a while.

Lastly, in comparing pricing: Anything DONE RIGHT, isn't cheap. Go the best route, it pays in the end.

A similar cable set up will be a little less expensive, but you'll have one well trained left calf with decent HP numbers.

Hope this all helps.

I am still trying to decide. I certainly value ease of operation. I am planning to use the 306 making around 340 hp with the TKO 600 transmission with a Ford clutch and flywheel.

-

I have originally decided on a cable for my build when its completed, but decided on a hydraulic setup. As of now, I will be ordering breeze components for the trunk drop, front battery and radiator components just to have at home and ready for when it's time to install. Reading the forums is becoming invaluable to me as I get a mental picture of what everything looks like. I am super stoked on the completion date of 4/11 and getting garage ready for delivery. I have a new friend AL_C that extended a helping hand, and since his knowledge of his build and the build school will solve whatever issues may arise from my build.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

_1486_detail.jpg)