Hi,

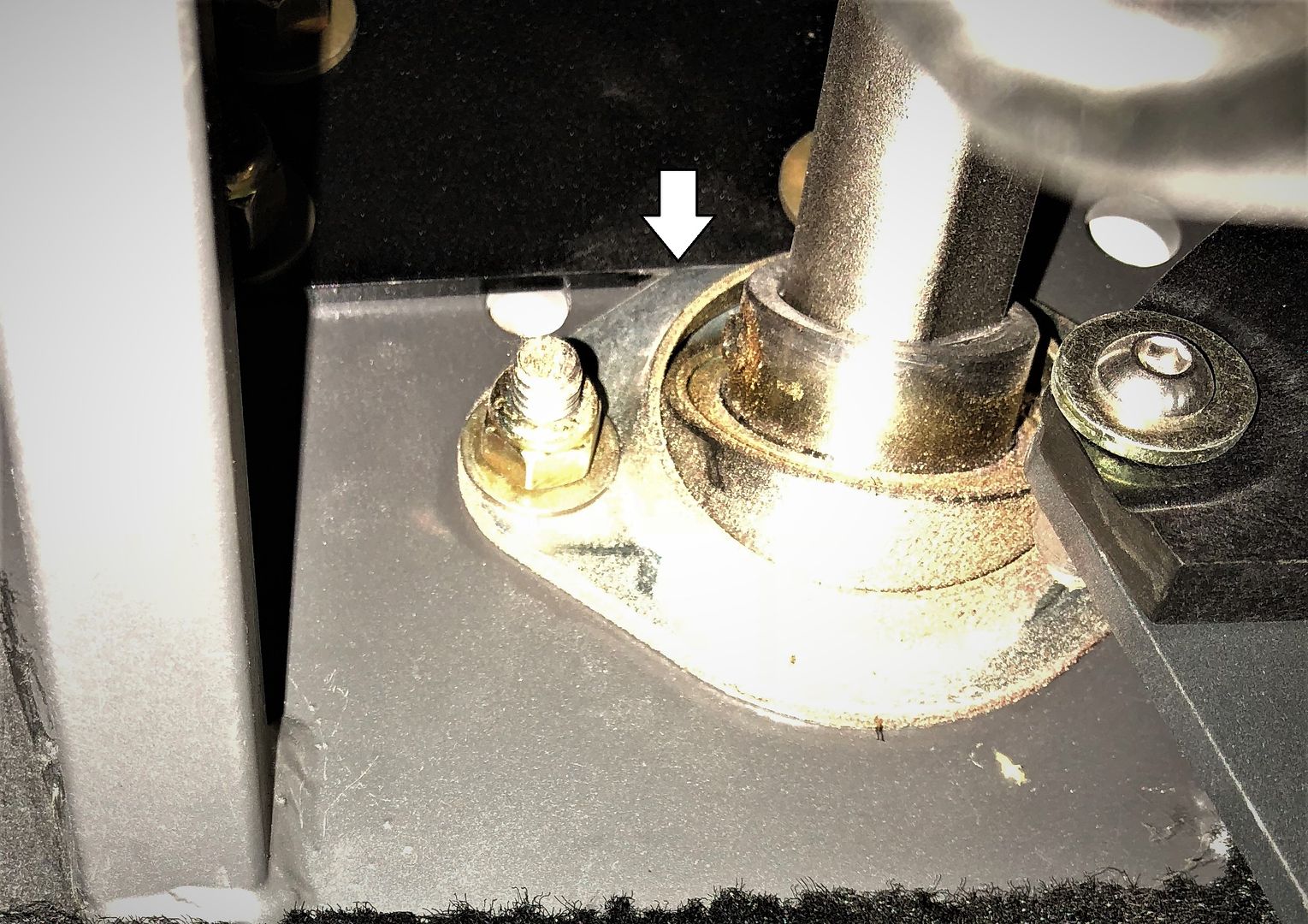

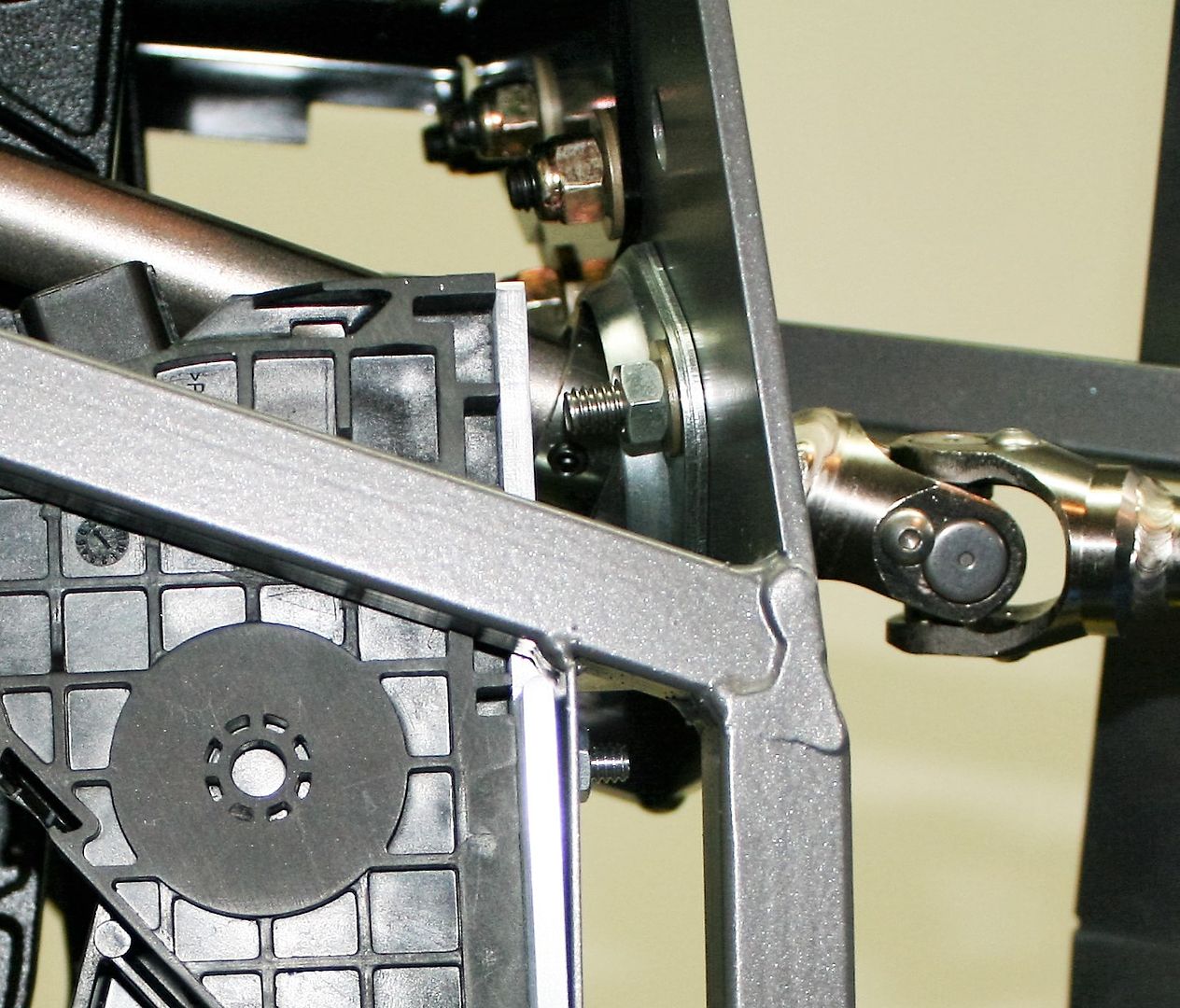

It seems as if the steering shaft is a little too long. With the steering shaft all the way against the lower bearing there is not enough room to put the end on the power steering rack. I called ffv and they said to dismount the rack and put the bottom on the end before mounting the rack. I did this and it is very tight. In fact to be able to slide the upper shaft into the upper bearing the bottom moves the steering rack.

Some possible solutions.

1. Let it bind- I donít know if that will reduce the life of the steering rack, the lower bearing, or the u joints.

2. Move the lower bearing to the opposite side of the firewall- I would have to clearance the pedal mount plate. There already isnít much space between the mounting bolt and the edge.

3. Cut and shorten the steering shaft about an inch- the shaft is Chrome plated and I would want to re chrome it.

Iím leaning towards option 3.

D9DBF17C-E341-4B8B-8A65-CA2F65C626F6.jpeg

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote