-

Member

Advice needed: Most reliable hydraulic clutch setup? SBF, T5 (dupe'd post)

Advice needed: Most reliable hydraulic clutch setup? SBF, T5 (dupe'd post)

Replacing the clutch plates at the moment and I have the engine, SBF 302 apart from the T5 at the moment and was wondering what the best hydraulic clutch slave/pedal setup is?

What is your experience? What would you do differently?

I have MKIII and a '87 'stang pedal box, not adverse to replacing it.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

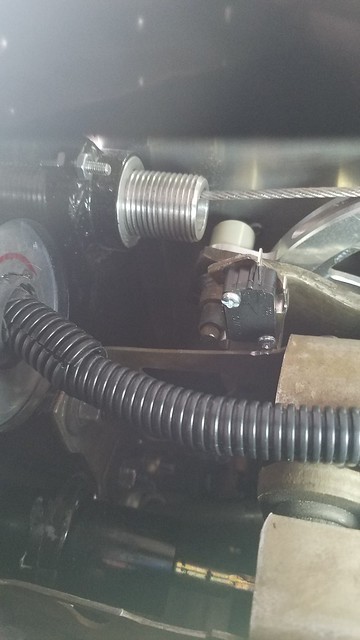

I love the kit I purchased from Forte's Parts Connection. I did have to clearance the slave cylinder mounting bracket; check out post #224 of my build thread for details (https://www.ffcars.com/forums/17-fac...r-build-7.html).

John

MK IV Roadster #8631

Ford 302, Holley Terminator EFI, T5z, 3.55 Rear End, IRS, 17” Halibrand Replicas (9” front, 10.5” rear), Nitto 555 G2’s (275/40ZR17 front, 315/35ZR17 rear), Fast Freddie’s Power Steering, F5 Wilwood Brakes, FFMetal’s Firewall Forward, Forte’s Hydraulic Clutch & Throttle Linkage

https://www.ffcars.com/threads/phile.../#post-4776313

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

MkIII with Wilwood pedal box, 351W, T5, Ford Racing King Cobra clutch. At recommendation of others during my build I installed Mike Forte's hydraulic clutch. Simple install and very easy action - highly recommended - and Mike's great to work with.

FFR6243RD, MkIII, 3.55, IRS, pin-drive width, carb'd 351W, T5, 1/2 dropped butt, Fortes hydraulic clutch, deep dish AC-III wheels by Team III. 9 year build; NY registered 7/18/2016 - "Sweet 16" winner at 2016 Taconic State Nationals 5 days later ... in 'rough as hell' gel coat for the foreseeable future! Build Blog - Leave me a comment!

Register your car with the Factory Five Cars Rule! mobile app available from the app store

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Hydramax Hydraulic clutch is what I'm using but if you want the hydraulics on the outside of the bell housing get Mike Forte's set up.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Why do you need to replace it ? I know that it the fad today, but...

Cable actuated clutches have worked very well for millions of Mustangs from 1979 to 2004. Just avoid the cheap aftermarket cables, and keep on driving. Even if it does fail, it is a quick and easy fix. If the hydraulic clutch fails, I would not even guess how long to fix.

If I were building today, I would use a cable clutch.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Member

Thanks for the feedback gents. :-) I was interested because my back has been giving me trouble and I'm looking to see if I can reduce some of the effort needed to drive the roadster. A little neural foraminal encroachment among other things which feels like someone is trying to push a dull point slowly into my back. Got word today that my doc thinks there's a simple fix for part of it.

-

In that case, Mike Forte makes a clutch fork extender that reduces the clutch pedal effort.

Down side is the when the effort is reduced, the travel is increased.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Member

Another vote here for Mikes Hyd setup. I have a wilwood pedal box but the setup is clean and works very well. 351 and T5 setup. Would do it again and the pedal effort is smooth and easy.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

My standard response regarding the clutch cable vs. hydraulic has several aspects FWIW: Cable works fine if (1) There's a smooth and direct path from the footbox to the bell housing reasonably away from heat, e.g. headers. Heat is the #1 killer of cables. (2) Use a high quality cable. Genuine Ford or Ford Performance. (3) If you have the Wilwood pedal box Factory Five clutch cable conversion setup, make sure it's the latest version that pulls in line with the pedal. Not the previous one that pulls at the end. (4) Don't over clutch. Get one that matches your power and intended driving. I see guys putting maybe too heavy clutches in their builds, which unless you're spending big bucks for a dual disk setup, translate into a heavier pedal. Agree the fork extender reduces effort. But it's good that the increased pedal travel is mentioned. Often it's not. There's no free lunch.

I've used Mike's hydraulic setup a couple times, and it works well once installed and properly setup. I suspect it might have slightly less pedal pressure. But I've not done a comparison with everything else being the same. Certainly handles the routing issue if a cable doesn't set up well. Again make sure to use the right duty clutch. Also take a look at properly matching the master cylinder with the slave. I've had good luck with changing from the 1-1/8 inch master that Mike provides to a 1 inch master. Still provides the necessary clutch throw, but with reduced effort. It's what I have in #8674 and it works well.

I'm going to try a Tilton HRB in my Coupe build. That's what they call it. Hydraulic Release Bearing. It's simple and a little more cost effective. Supposedly the lowest effort. But time will tell. Certainly some risk because a malfunction means major disassembly. Unlike an external setup.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Member

I'm staying with a stock 1987 Mustang Cobra GT 5.0 cam and heads. Switched over to a Edelbrock Performer RPM, Flame thrower distributer and a FiTech Easystreet with shorty headers. Expecting a bit more power but nothing near what some of you folks have. :-) I just want a cool summer street ride for fun... maybe run over a few cones. Doing it up as a street Cobra with an under-car exhaust and a few mods I'll show later.

Just discovered some tiny cracks on the flywheel so I'm waiting on a replacement. Showed it to local tech and he told me a new one was better than grinding it. Going with a standard pressure clutch. Nothing wild.

I've had a long time to figure what I'm doing for the build. I got this MKIII the month it first came out and pretty much had to store it as family, work and renovating 4 different homes took precedence. it's been way too long to wait but I'm on it now.

-

Brandon #9196

I want to start by saying I empathize with your back pain. I am on a flying waiver in the air force for l4 l5 disk protrusions. I have something that will work for you.

I have to say in your situation it sounds you may have talked yourself out of the hydro setup. I dont have any input on that and dont want to detract from the idea that it may be a great option. But let me tell you, I have a nice, high quality replacement AJUSTABLE cable (LMR) and it feels fantastic. I am using a king cobra ford performance clutch and have 475 flywheel hp and its holding great. The interesting thing is the pressure plate is feather light. I feel you have the ability to get what you want without hydro and it has less moving parts to maintain.

Good luck. Use a good cable, billet quadrant, firewall adjuster, foxbody pedal box, new pivot bolt, and a heavy duty maximum motorsport (LMR.com) fork with a good ford performance clutch and you will have all you need.

-

Brandon #9196

-

Member

Thanks for the pics! I am replacing the flywheel as the 30 yr old one has a bunch of hairline cracks radiating out from the center. What's the difference with 28 vs 50 ounce? I think my '87 5.0 HO is a 50 ounce. I looking to replace it with the same Ford part number to be sure it's compatible.

-

Senior Member

Originally Posted by

CNIdog

Thanks for the pics! I am replacing the flywheel as the 30 yr old one has a bunch of hairline cracks radiating out from the center. What's the difference with 28 vs 50 ounce? I think my '87 5.0 HO is a 50 ounce. I looking to replace it with the same Ford part number to be sure it's compatible.

It's critical that you use the right flywheel (and harmonic damper on the nose of the crankshaft) that's intended for your engine. The rotating assembly is balanced with the appropriate imbalanced flywheel and harmonic damper. I agree your 87 5.0 is probably a 50 ounce imbalance. But absolutely make sure.

Last edited by edwardb; 07-29-2018 at 10:35 PM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Brandon #9196

My stock 5.0 was 50 oz, my new setup is 28 oz. I believe the 351 windsor was 28 oz. Just make sure as edwardb said.

-

Member

Pretty sure it's 50 ounce. I was at the local Ford dealer to verify. Too bad they don't sell Ford Racing catalog stuff locally. I'm shopping for new harmonic dampener too. I figure 30 year old rubber component of the original is probably shot. My engine build has been done with out cracking open the heads or playing on the bottom end other than a new Melling pump, pickup and front sump pan. Drilled a front dipstick hole in the timing cover boss. Every thing I'm doing is strictly bolt-on replacement which I can pull off and throw on another 302 HO sitting in the garage if this one goes bad. It was running fine in the wreck I bought almost 15 years ago in anticipation of buying a MKII. Ordered the MKIII on the first "special" deal FF offered that year. The 2nd 302 I got in a swap for the 308 rear axle from the donor and a couple wheels. I may have one of the longest build cycles on record ;-)

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote