This is killing me - yet another crisis of confidence. Thank God for this forum! I'm trying to keep everything in perspective, but progress is pretty darn slow... (time available isn't helping!)

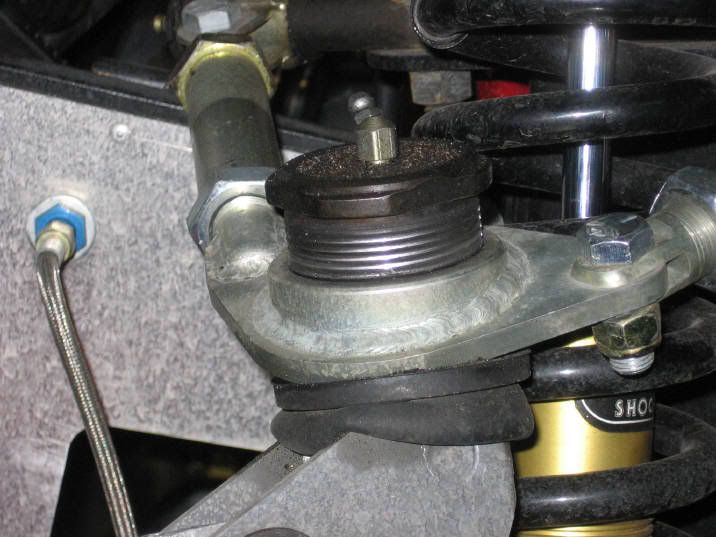

OK - check out the photos. So I get the ball joint threaded into the UCA. Nice and smooth. Easy to turn by hand, actually. It would appear that the threads do not go all the way to the "cap" on the ball joint. The question is - how far do I need to thread this on? The manual doesn't seem to indicate one way or the other. This is one thing I didn't photograph at build school! Does it need to bottom out on the cap of the ball joint, or do I have this screwed on far enough? ( I used blue thread locker on it already...)

ball1.jpgball2.jpg

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote