Primary item:

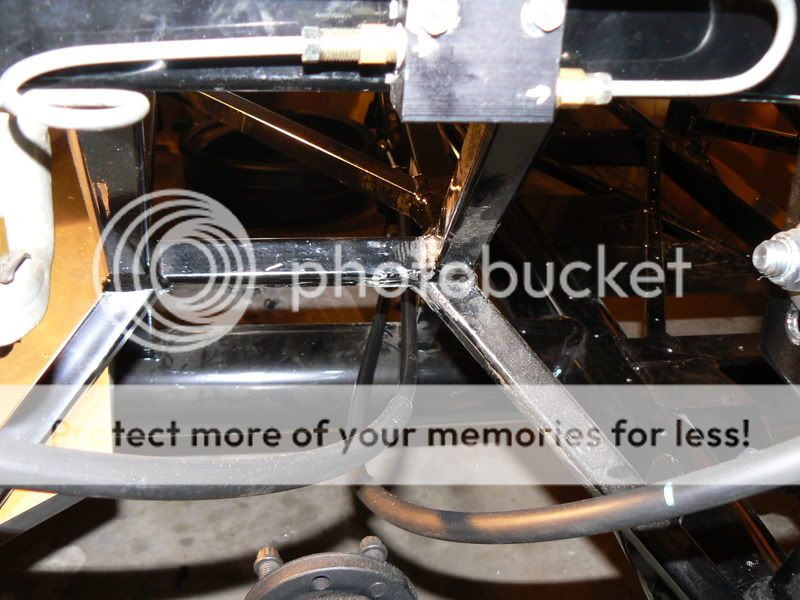

I am working on my Mk4, using a 1994 Mustang Gt coupe donor. The cables are direct NAPA replacement Mustang e-brake cables for the 94. The handle itself is also from the 94 donor.

The handle is installed using the FFR provided hardware bolt and slide-on clamp. The cables are sitting nicely in the chassis bracket near the location of the handle.

Once the "T" coupling is attached to the 2 rear cables tension is immediately applied to the cables, there is no slack.

When the handle is engaged the lower cable pulls in at least twice the distance of the upper cable.

I swapped the position of the cables, and the result is the same; the lower cables gets pulled in at least twice the distance.

So it's likely something obvious that I'm just not seeing after hours of messing with it and searching the forums for a SN95 specific solution.

https://thefactoryfiveforum.com/images/attach/jpg.gif

https://thefactoryfiveforum.com/images/attach/jpg.gif

The secondary item is that it appears that the handle is way to close to the transmission tunnel. And once the carpet is added there will be near zero clearance.

https://thefactoryfiveforum.com/images/attach/jpg.gif

https://thefactoryfiveforum.com/images/attach/jpg.gif

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote