Thought I'd re-post my build thread from the "other" site. I took the opportunity to fix some things and correct some spelling errors.

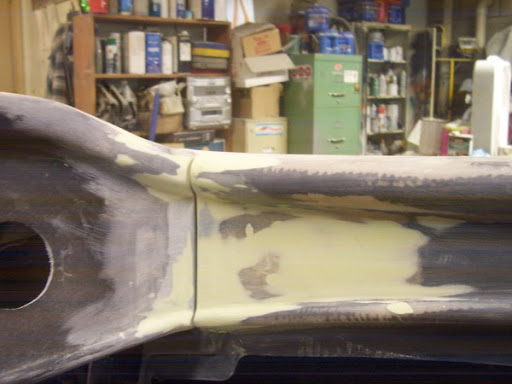

I figured it was about time to start a build thread of my own. I will be working on the '33 sporadically so I waited till I had something accomplished before posting. I'm kind of going about my build a little differently than the manual. I'm mocking up all the "hard" parts so I can make sure (hopefully) there won't need to be any welding or cutting done after the frame is painted. I'm using a transmission that is not supported by FFR, so modifications will need to be made for that too.

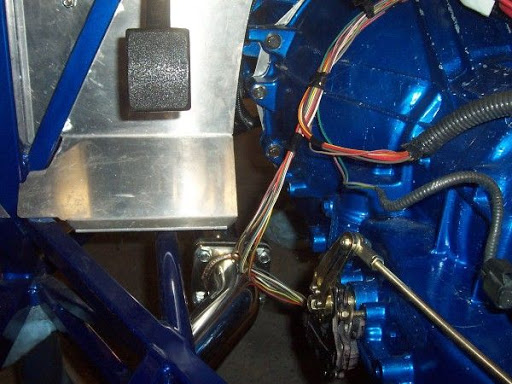

The assembly has been going pretty well, with the all the minor issues that have been brought up on the board here (grind down the large nut on the steering rack, trim some of the shock spacers, sand down the spindles so the hubs slide on, cut the steering shafts down - more on this later)

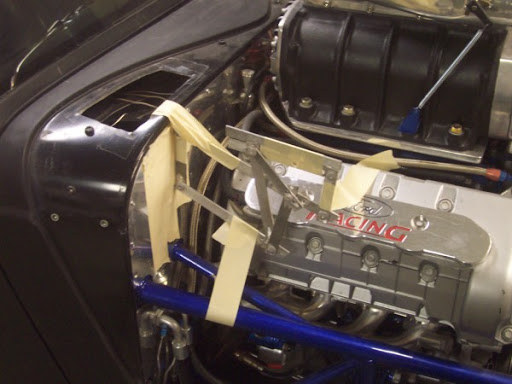

I first installed the motor to get a feel for what things might not fit:

I'm using a Mark VIII 4.6 DOHC with a custom blower and Megasquirt EFI and ignition system. The transmission is a 4R70W also from a Mark VIII. I'm using a Baumann aftermarket controller for the transmission. I had built this motor a couple years ago and ran it in another car. It's kind of unique so I wanted to use it for this build.

I got the front suspension mocked up and the brake hardware installed.

I got the rear axle hung. It's from a '96 GT so it has the 5 lug axles, limited slip, 3.73 gears and disc brakes. One thing that became obvious after hanging the rear axle was there are a bunch of extra brackets for the optional three link welded to the frame and shock mounts. I think I will be cutting them off and or filling any extra holes just to clean it up a bit.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

)

)