Itís been a couple weeks since an update. But Iíve been busy. Mostly under the general category of plumbing. So button up. This could get long. The build manual shows basic setup and routing for everything. But based on my engine choice and other build decisions, only some of itís applicable. So after doing lots of studying, along with reviewing other build threads, dove in.

First a quick word about my thought process. As anyone who has built one of these knows, regardless of model there are a lot of interdependencies. One thing can easily affect another. Intentionally or not. If you haven't found that out yet, at some point you will. My approach is to start with things that either canít move or have limited flexibility. Then move to the next thing in line with a little more flexibility. And so on ending with whatever has the most flexibility.

So with that started with the e-brake cables. Very often those have a fixed or very limited routing that takes into account the cables, attachment points, brakes, etc. That definitely was the case with this build. The optional Wilwood rear brakes have the e-brake attachment on the front and the cable comes in from the bottom. Really only one routing along the floor and through the chassis. Both are connected and working. I don't expect to use the e-brake too much to be honest. With the park position on the auto trans locking the drivetrain. But it's there. I had these same Wilwood single cylinder rear calipers on my #7750 Roadster build. They needed helper springs added at the cable attachment to release reliably. Others experienced the same thing. Doesn't look like these do. Looks like Wilwood beefed up the circular spring on the e-brake lever.

Next up, everyoneís favorite. Brake lines. As I mentioned in my last update, Iíve done rigid SS in my last several builds and really like the final product. But itís a lot more work and even with the right tools can be challenging. Couple that with my go-to source for SS tubing, where I could buy in straight lengths versus coiled, is no longer allowing counter sales. Theyíve gone 100% to on-line sales. Theyíll sell me the tubing, but only shipped and coiled. Even though theyíre about 20 minutes away. Just not wanting to try to straighten SS tubing. So for this build, I decided to go steel. I know many like NiCopp. But I prefer the slightly stiffer steel. The Classic Tube C3 Tubing I bought from Summit came coiled. But fairly large with soft bends and straightened OK by hand without any special tools. Itís zinc coated and in this application (e.g. garaged, fair weather car) not too worried about corrosion or rust. My Eastwood professional flaring tool easily makes dead-on perfect flares in the steel every single time. More about that laterÖ

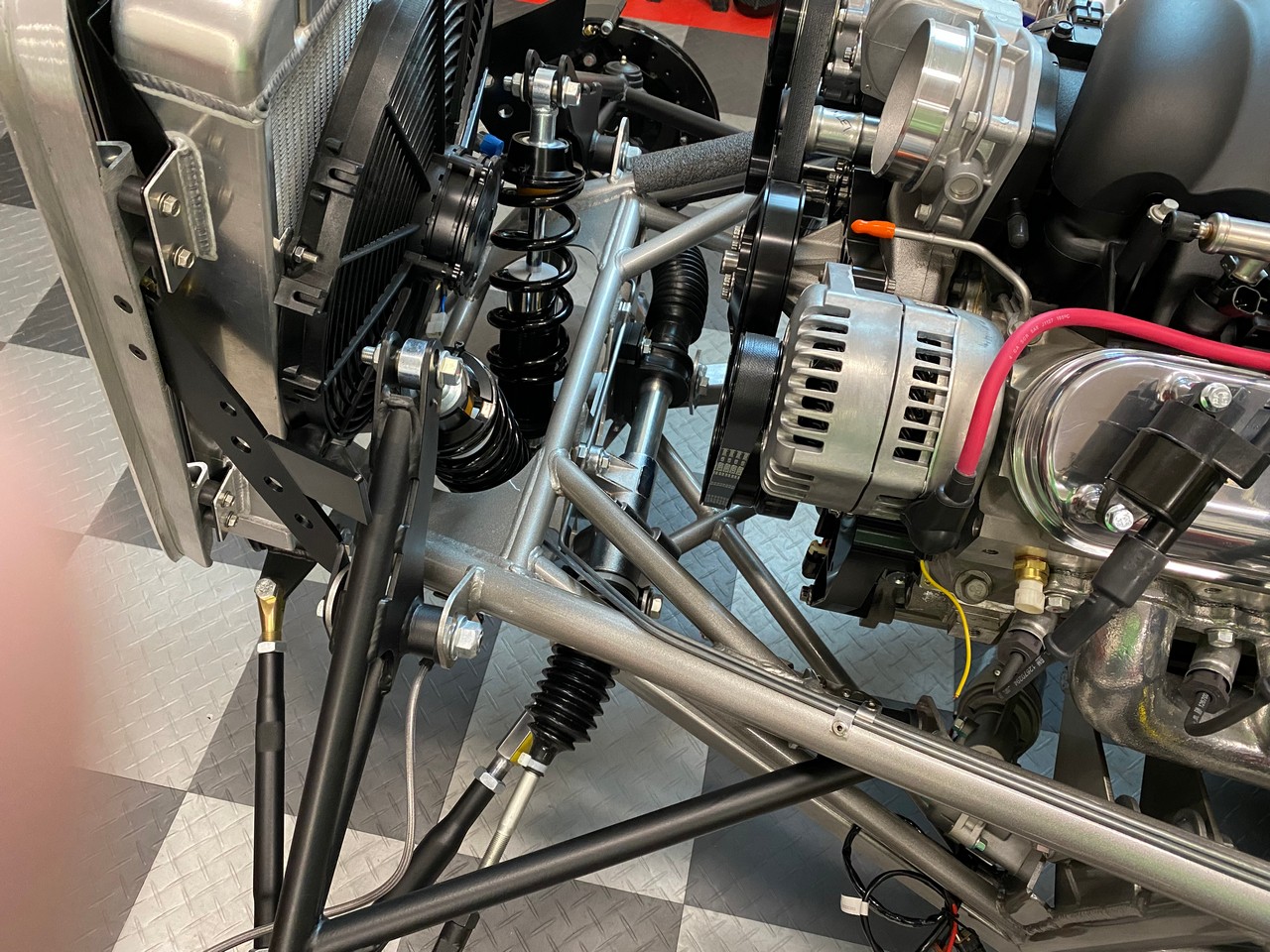

For the brake line layout, in the front I deviated quite a bit from the build manual because of the dual master cylinder on the firewall (versus the Wilwood pedal box inside) plus the master cylinder has two lines for the front brakes. One to each side. So I routed the two lines along the top of the round frame rail rather than on the lower frame rail as in the manual. If I were going to have an open engine bay, may not choose the top of the rail. But Iím going to have the side covers. One to the LH side. The other crossed over to the RH side. Pretty straightforward.

For the rear brakes, went down the firewall, along the underside to the back, up to the LH side where it feeds there plus crosses over to the RH side. Similar to how shown in the manual.

All the runs are one piece. No unions. Relatively easy to do except for the front to back run. Note I did use the kit provided brake lines. Used them for patterns. Once I had a piece fitting the way I wanted, then duplicated in the single steel line. I donít trust myself to make them exactly right the first time. Just donít do it often enough.

With that done, no reason not to put fluid in the system and bleed it, right? Good way to check your work plus cross off a pretty big milestone. Wilwood was nice enough to include fittings and hoses for bench bleeding their dual master cylinder. Nice.

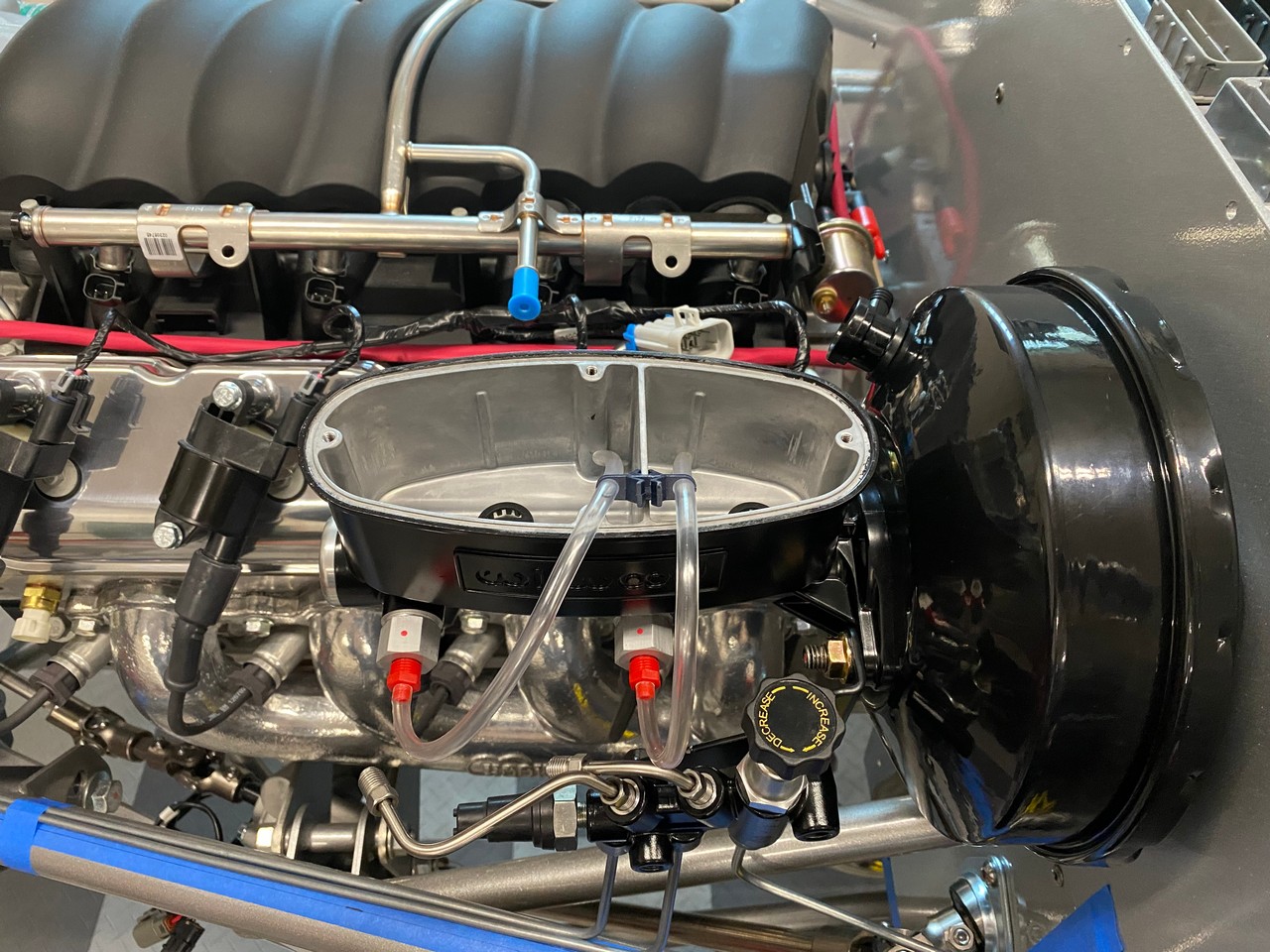

With that, a pretty big mess. All four connections between the MC and the compensation valve (visible in the picture above) leaked. With nothing more than gravity pressure in the MC. Note these are SS lines that were included with the power brake assembly I had so much trouble getting after I ordered it. Talked about it a bunch early in the build thread. Tried the usual practice of backing off the tube nuts a bit and re-tightening. Nothing helped. So, drained all the brake fluid out of the MC (man I hate that stuff) and took things apart. What I found were the worst flares you can imagine. Especially the front longer one. Crooked and off-center. Just very poor quality to say the least. I had some scrap SS tubing on hand, so made new pieces. Better, but still leaked at the MC. Took things apart again and found that the Wilwood flare adapters into the MC were damaged due to the bad flares. The adapters are aluminum. The brake lines are much tougher SS. And I probably was too aggressive tightening. Regardless, the seats were damaged to the point theyíd never seal. Fortunately, Summit had the Wilwood adapters in stock and on my porch the next day. After sleeping on it, decided to make new lines again but this time out of steel. A little more malleable and maybe give me a better chance of sealing and not tearing up the aluminum. So thatís what I did and with new adapters and new lines now no leaks. Good grief. Didnít see that one coming.

For bleeding, for all my builds Iíve done pressure bleeding using air pressure in the reservoirs. Not an easy option with the very traditional dual MC with integral reservoir. So decided to use the standard pedal down/pedal up bleeding with my wife as the pedal operator and me opening and closing the bleeders at the calipers. After some explaining on how it would work (which I really didnít think was mansplainingÖ) went around all four corners twice and had a hard pedal. One leak at a banjo fitting I didnít have quite tight enough and everything else was good. Went around one last time to confirm zero bubbles and called it good. Further testing and no leaks or runs. Brakes all work of course. Pretty happy about that. One thing I noticed FYI is the Wilwood 6-piston front calipers (same as on my Anniversary Roadster and Gen 3 Coupe) no longer have separate bleeders on each caliper. You used to have the bleed those calipers twice. Once on each side. Now only has bleeders on the inner caliper. Another Wilwood change. But makes things a bit simpler.

Next up, fuel lines. Again, Iíve used 3/8Ē rigid SS on my last builds but decided to go with all -6 AN SS flex. Just to keep it simple plus again not being able to easily get straight tubing. Also decided, as I mentioned before, to put the regulator in the back by the tank rather than run two lines all the way to the engine. I already had the Aeromotive regulator. So itís mounted in a not too handy spot. But Iíve found once set I havenít had to adjust. So no big deal. Easy to see why the GM Corvette fixed regulator many use is popular to mount back there. Other than the regulator location, the setup is the same Iím used on multiple builds now. A Pro-M Racing full 3/8Ē pump hangar, Trick Flow TFX canister fuel filter, and -6 AN flex and connectors hooking it all together. A very solid and robust setup that's probably overkill. But it works and has been trouble free in the other builds. Iíve pretty much standardized on using Aeroquip hose and fittings. Lots of choices. I just find the quality and reliability to be excellent and Iím used to how it goes together. I pressure tested each hose section after putting the ends on. This is what I ended up with. I angled things to cut down a bit on bends.

The fuel line goes down a frame rail (seen in the previous brake line pic), along the bottom, up the firewall, and over to the connection on the LS3.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

) used a digital micrometer and noted the actual values. This was the amount to remove on both sides. Then removed the doors.

) used a digital micrometer and noted the actual values. This was the amount to remove on both sides. Then removed the doors.