-

11-06-2023, 01:15 PM

#161

Senior Member

One more question on power --> Originally I planned to run an 8AWG +12V feed from the switched side of master disconnect over to the Blue Seas terminal block behind the dash. Would there be any concern if I ran a 4AWG instead? I might add a 2nd fuse panel with 6 additional circuits behind the dash, and I was thinking the 4AWG would be safer to power both the RF fuse panel and the new fuse panel daisy chained off the Blue Seas terminal block. Any concerns with this? The Blue Seas terminal block can handle plenty of current (100 amp) so I'm not concerned with that part - just wondering if there is any downside of running the 4AWG cable which I already have plenty of from the FFR kit. I'd need to buy some 8AWG wire, so there's that too (but that's a minor issue).

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

12-04-2023, 10:06 AM

#162

Senior Member

#9644 updates - dash and power wiring

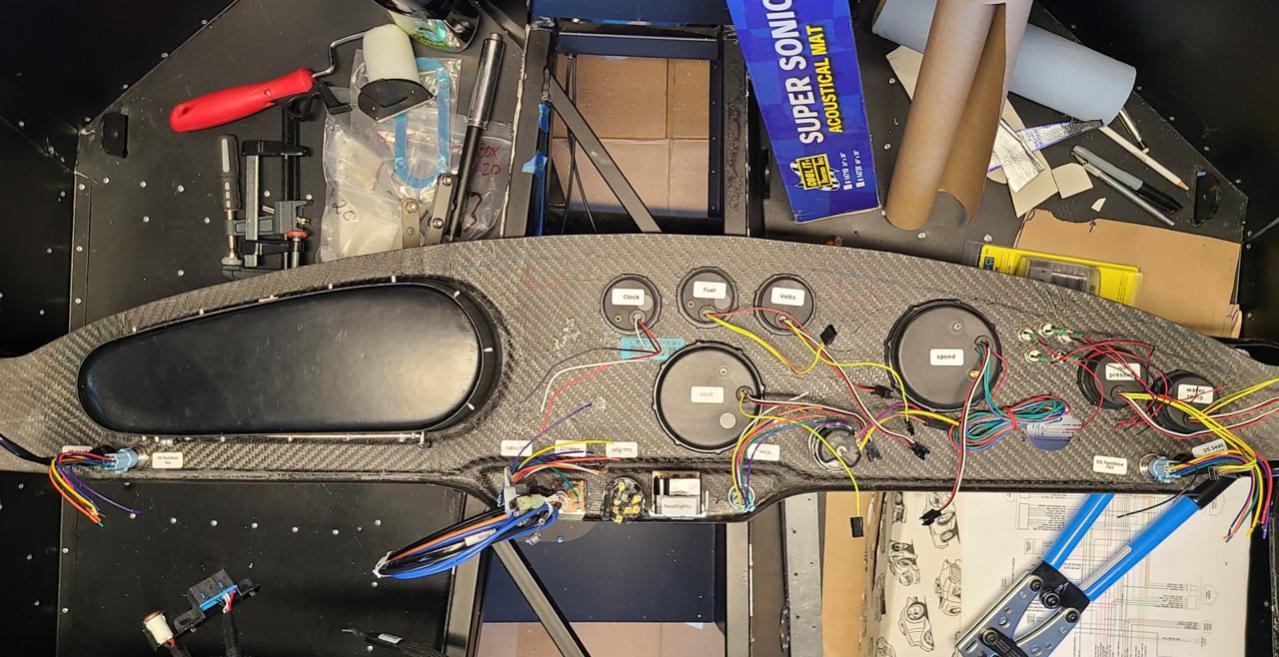

It's been a little while since I updated, but I've been slowly working through the electrical. My primary goal is to finish the power wiring and re-routing the Coyote harness starter wire and main harness ground to run with the power from the master disconnect to the starter location. All this has to be completed so I can re-install the drivetrain. As of last night, I finally finished those items, as well as finished mounting all the switches & knobs on the CF dash. I haven't completed the dash yet (i.e. haven't daisy chained the gauges or attached the dash harness), but it feels good to get all the switches mounted.

Here's the dash - I'll post more about this later along with a full breakdown of some of the modifications I had to do, but the main item is that I now have all the '65 Mustang switches mounted. I ended up sticking with the stock FFR headlight switch instead of the '65 mustang headlight switch, and I was able to modify the shaft and Mustang knob so it works (maintains 65 mustang knob appearance). But I am still using the '65 Mustang wiper knob (rotary), and heater knob (w/ FFR heater kit switch).

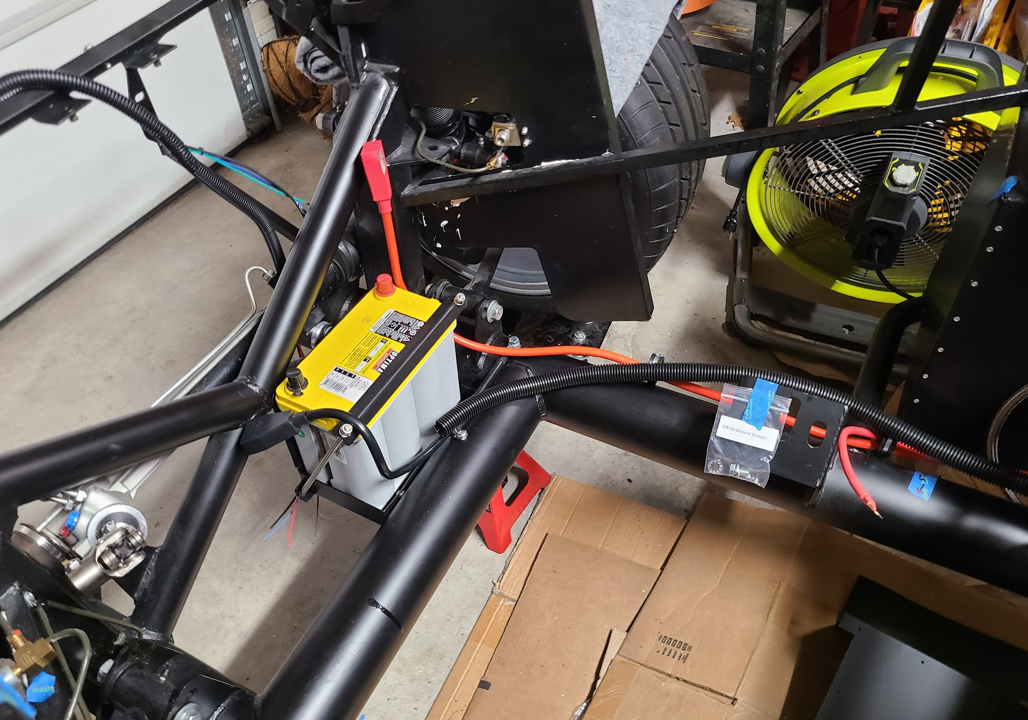

I got the battery installed (Optima Yellow Top 8071-167) - it's a Group D51 size and installed in the front mount location with the Breeze box. No issues with that:

For the power wiring, I followed edward's 20th anniversary build, as many others have done. I also switched to #2 AWG battery cables with a #4 going to the starter. I de-loomed the ECU leg of the Coyote harness so that I could pull out the blue starter wire and rout that down with the battery cables to where it needs to end up on the passenger side near the engine mount. I also ran the Coyote harness blunt-cut #10 AWG ground wire with these items and ran it all the way up to the front battery ground location. Finally, I ran a wire through the Coyote ECU leg that I can tie into the Coyote Cooling Fan wire (orange) and ran that back up the loom into the dash so I can run it to my dash indicator light which will show me when the fan is running.

Here's the Coyote ECU leg after pulling it out of the 1" split loom:

This is what it looks like as I was re-adjusting the wiring. The blue wire running with the power cables is the starter wire (from Coyote ECU leg) - it terminates near the PS engine mount along with the starter +12V switched from the Master Disconnect. The blue wire hanging down is the fan wire running back to the dash for the indicator light (I didn't have any orange wire so just used what I had). All I can say is that my fingers are numb from getting these cables out of the loom and peeling off all that damn tape.

And here it is all buttoned up and put back into the split-loom. I may re-wrap these with some cloth loom tape and I also need to buy some smaller cable clamps. I bought the 1.125" ones from DelCity but they are way too big...I think I need the 1" or maybe even one size smaller than that (7/8" looks like it would be the best but I haven't found any that size yet). 3/4" looks like it would be too small:

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

12-04-2023, 01:13 PM

#163

25th Anniversary #9772

Originally Posted by

dbo_texas

Here's the dash - I'll post more about this later along with a full breakdown of some of the modifications I had to do, but the main item is that I now have all the '65 Mustang switches mounted. I ended up sticking with the stock FFR headlight switch instead of the '65 mustang headlight switch, and I was able to modify the shaft and Mustang knob so it works (maintains 65 mustang knob appearance). But I am still using the '65 Mustang wiper knob (rotary), and heater knob (w/ FFR heater kit switch).

I got the battery installed (Optima Yellow Top 8071-167) - it's a Group D51 size and installed in the front mount location with the Breeze box. No issues with that:

love that dash setup! very nice!

-

12-04-2023, 03:33 PM

#164

Senior Member

Thanks - I got the inspiration from Lidodrip and a few others who've used the 65 mustang switches/knobs/bezels. They really look clean on this dash. Now I just need to figure out how to wire everything up!

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-29-2023, 12:12 PM

#165

Senior Member

T56 Reverse Light & Reverse Lockout wiring questions

I'm routing my rear harness, and I'd like to add some wires for a reverse light and reverse lockout.

For the reverse light:

I plan to use the reverse light function on my T56 transmission and already have the connector on the transmission (2-pin weather pack on the PS of near the front). Do I run +12V on ignition to one lead on the T56 reverse light connector, and then the other lead from that connector goes to the light in the back of the car? Then I would just attach the ground lead of the actual light to chassis ground? Is that the proper way to wire this?

The idea is that when you put the transmission into reverse, the reverse switch (on transmission) will close the circuit for +12V going to the reverse light. Just looking for confirmation before I add in my extra wires to the rear harness (will need to break out 2 wires ends in the area near the transmission connector).

For the reverse lockout:

I bought the reverse lockout from Forte's --> I need to see what needs to be routed for that connection as well (haven't researched it yet). I think there is a module (maybe a GPS? or maybe uses the speed sensor?) that I need to mount behind the dash, then run the connection up the trans tunnel to the dash. If anyone has bought/used the one from Mike Forte and can share details on how this works (i.e. the logic), please share! I will also go read the instructions that came with it  Probably a good starting point.

Probably a good starting point.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

12-29-2023, 03:04 PM

#166

Senior Member

It's just a NO switch, so 12V or ground will be enough to engage the reverse light(s).

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

12-29-2023, 05:51 PM

#167

Senior Member

Originally Posted by

Its Bruce

It's just a NO switch, so 12V or ground will be enough to engage the reverse light(s).

OK perfect thanks that's what I thought. I think I'll bring 12V ignition power to the switch, then ground it at the light in the back of the car.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

12-29-2023, 05:57 PM

#168

Senior Member

Originally Posted by

dbo_texas

I'm routing my rear harness, and I'd like to add some wires for a reverse light and reverse lockout.

For the reverse light:

I plan to use the reverse light function on my T56 transmission and already have the connector on the transmission (2-pin weather pack on the PS of near the front). Do I run +12V on ignition to one lead on the T56 reverse light connector, and then the other lead from that connector goes to the light in the back of the car? Then I would just attach the ground lead of the actual light to chassis ground? Is that the proper way to wire this?

The idea is that when you put the transmission into reverse, the reverse switch (on transmission) will close the circuit for +12V going to the reverse light. Just looking for confirmation before I add in my extra wires to the rear harness (will need to break out 2 wires ends in the area near the transmission connector).

For the reverse lockout:

I bought the reverse lockout from Forte's --> I need to see what needs to be routed for that connection as well (haven't researched it yet). I think there is a module (maybe a GPS? or maybe uses the speed sensor?) that I need to mount behind the dash, then run the connection up the trans tunnel to the dash. If anyone has bought/used the one from Mike Forte and can share details on how this works (i.e. the logic), please share! I will also go read the instructions that came with it

Probably a good starting point.

OK I think for the reverse lockout, after looking at the instructions, I just need to route 4 wires from the module behind the dash to the connectors on the transmission. One pair of wires to the lockout solenoid, and one pair to the VSS (speed sensor). I'm not using the speed sensor on the trans since I'm using the vintage gps speedo. So that should work out fine. There are also +12v ignition power and ground connections on the module that I'll connect behind the dash.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-05-2024, 10:36 PM

#169

Senior Member

Drivetrain Install - Part 1 (engine & trans prep and install)

At this point I've spent the last couple of months working on the electrical. I'll do a few separate posts later once the electrical is completely finished, but for now I've modified all the harnesses and installed them in the car. I've also installed all the Coyote specific harnesses & ECU. This was the gating item preventing me from reinstalling the drivetrain, so with that out of the way, it was time to re-install. I prepped the engine bay by disconnecting the steering shaft to get it out of the way. I also disconnected my front brake hard lines where they mount to the F-panels. I might have been OK leaving them in place, but since I haven't bled the brakes yet I just disconnected them to push them out of the way. I then removed the battery from the Breeze box. I probably could have left it, but again, it was easy to remove and get it out of the way. Once I lifted the engine off of the FFR Coyote stand, I also did a quick test fit of both headers to make sure the bolt holes all lined up, and thankfully they did.

Prepping the transmission mount: I had a hell of a time finding the correct fasteners, and found that whoever installed the mount the first time used the wrong size fasteners. Looks like they used 7/16-14 bolts instead of the correct sized 1/2-13 bolts. Some of the threads were damaged, so I re-tapped both holes and then installed with the correct size bolts --> everything snugged up well so I think I'm good with the fasteners. I also removed the shifter assembly to make it easier to install into the frame.

Question: For those with my same combination (Coyote + T56), did you end up using the spacers with the trans mount? The FFR Coyote Fitment instructions don't show them, but the FFR Complete Kit instructions do show them. I'm not sure which one is correct for the Coyote + T56. I didn't install them, but I also ended up with a pretty big 1/2" gap between the trans mount and the A-frame after installing the engine. More questions on this later...

A-Frame Install: Also couldn't find these fasteners so went digging around in my parts bin and found the correct sized bolts and nuts. Install was no problem --> I installed it on TOP of the FFR frame tabs, but I've seen some folks say it may work better mounted below the tabs. So I may need to swap this - I need to study this more and figure out which will work best with my combo.

Engine Prep: Some of the work was already done by Forte, like the oil pan and oil filter nipple. The only think I really had to do was install the Vintage Gauge oil pressure sender and water temp sender. Had to dig around for quite a while to find the correct brass adapters, but ultimately got them both installed without too much trouble. I used Permatex high-temp thread sealant instead of Teflon tape (per FFR instructions) on the NPT threads for both.

Question: for the oil sender plug coming from the engine harness, will this be used at all or can it just get tucked away somewhere and secured?

Coyote Engine Mount Spacers: These 1/2" spacers come with the Coyote Install kit from FFR. No real issues with this, other than again having to dig around to find the correct fasteners (notice a trend here?). Overall, no problem with installing these per the instructions.

Drivetrain Install: We used a 2-ton hoist with a leveler and extended the boom all the way out (on the 1/2 Ton setting). This allowed us to come in from the front. We had the back of the frame lifted on jacks, and the front end was sitting on tire dollies to lower it a little bit. This helped with getting the transmission over the radiator 3/4" frame bar at the front. From here, it was just a lot of small movements - one person to steer the transmission, one person to steer the hoist, and one person keeping an eye on clearances all around.

At this point the engine was about 2" above the mounts. So it was time to install the headers while you still have some amount of access.

Last edited by dbo_texas; 02-05-2024 at 11:38 PM.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

02-05-2024, 11:34 PM

#170

Senior Member

Drivetrain Install - Part 2 (Headers Install, Driveshaft IRS adapter, driveshaft)

I have the FFR Coyote Full Length stainless steel headers (p/n 16267). I've read that it's best to install these onto the engine when you are about 2-3 inches from seating the engine on the mounts. So with the engine/trans mostly installed, we gave it a go. The gaskets that came with the headers were folded in half in the box - not sure how that happened, but I didn't want to risk the crease causing any issues so I bought some new gaskets. We'll call it a $35 piece of mind purchase. I ended up going with some Remflex #3609 header gaskets as many others have used.

We started with the driver's side header. Before we installed the engine, I removed all 16 of the header studs that came installed on the engine. I decided to use all bolts instead, and I measured the thread size on the studs to be M10x1.5. To install the header, one person held the gasket in place, while a 2nd person placed the header over it and then got all the bolts started. For the bolts, I replaced the bolts provided by FFR and went with the Stage 8 #8914 locking bolts. These are great because they have a locking tab that you butt against the header tube, and then an little clip to hold it in place. This prevents the bolt from rotating counter-clockwise and loosening. Since these have locking hardware, I didn't use any Loctite but instead opted to use some anti-seize on them. Not sure if that was needed or not, but I don't think it could hurt to prevent some headaches in the future if I ever have to remove the bolts.

Here you can see a closeup of the Stage 8 header bolt with the locking tab and clip.

Let me just say that I hope to God I did this correctly, because I don't ever want to have to remove and reinstall these headers. What a pain to install. On the DS especially, accessing the bolts is extremely difficult. I used everything in the toolbox (universal joint sockets, box end wrenches, extensions, etc). The FFR instructions do not give any recommendation on torque, so after doing some searching on this forum I found several recommendations to go with something in the 18-24 ft-lb range. I decided to go with 22 ft-lb. On the DS I could really only use the torque wrench on maybe 3 or 4 of the bolts, and on the PS probably 6 of them. For all the others, I used my finely calibrated hands to gauge how much to tighten them based on the ones I could access. Anyhow, I got them all installed. The PS was way easier to do vs. the driver side. All the bolts are more easily accessible on that side.

With the headers installed, I wanted to install the driveshaft IRS adapter and driveshaft. Once again, I had to go hunting for the correct bolts because they weren't with my adapter. After some digging, I ended up finding the correct bolts. They are socket head cap screws, size M10x25. I read on the forum that some 4 should be M10x20, and 6 should be M10x25, but all 10 of mine were M10x25 and they seem to work. The adapter uses 6 of these bolts going into the counterbore holes on the adapter and threading into the IRS joint. The remaining 4 are used to secure the driveshaft to the adapter. My adapter was the clear-zinc plated version, not the yellow-zinc one. I inserted the driveshaft before making the final engine push and this allowed me to get all the bolts installed. I didn't get any pictures of just the adapter installed on the IRS pumpkin, but the install was pretty straight forward. I torqued the bolts down per FFR instructions and applied some blue Loctite.

The driveshaft I have is FFR p/n 16038 (ROADSTER 31 SPLINE 8.375" DRIVESHAFT FOR 2015 IRS) which I'm pretty sure is the correct one for the Coyote + T56. After installing, it looks like this:

With both headers+gaskets on, and the driveshaft adapter and driveshaft installed, I went ahead and dropped the engine onto the mounts. This last 2 or 3 inches was quite difficult and I had to keep readjusting the transmission. I was finally able to get the mounting studs through the engine mount slots on both sides of the frame. Here's how both sides sit in the engine mounts:

Driver's side mount --> the stud is sitting about .375" above the bottom of the slot in the mount. Question: Does this look correct?

Here's the passenger side mount. It is seated at the bottom of the slot.

There are a few items I don't think look correct with my transmission mount and possibly the driveshaft, but I'll ask some questions about those in the next post. I haven't looked at the pinion angle or driveshaft angles yet --> I need to do some more research on what this should look like. As it stands, the driveshaft is pretty much straight between the pumpkin and trans and I know that isn't correct. So something is off.

Despite the issues w/ the transmission mount (to be detailed in future post), this still feels like a big accomplishment. With the engine back in, I think I can start reassembling a ton of items (radiator, hood hinges, coolant expansion tank, reservoirs, etc). Here's the final result:

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

02-06-2024, 12:56 PM

#171

Senior Member

T56 interference, A-frame Modification, Transmission Mount, Driveshaft Installation

When I installed the drivetrain I found that I couldn't get the transmission mount to sit down on the A-frame. After some back and forth troubleshooting (detailed in THIS THREAD), here is a summary of what I found and how I fixed it.

1) T56 & A-Frame Interference & Fix:

It turns out the T56 transmission body was hitting the A-Frame, preventing it from seating all the way down on the transmission poly mount. After contacting FFR & some suggestions by Mike Everson, I determined that sometime after my kit was built (2019), FFR changed the A-frame design and shortened the plate spanning the two legs on the A-frame. You can see it very clearly here - my setup on the left (showing the T56 hitting the A-frame plate), and on the right is a picture FFR sent me of their current A-frame. I think Mike Everson said the A-frame was modified around the time The Tremec TKX came out.

I'm not sure exactly how much they shortened it but it looks to be about 1.5-2" (using the FFR "5" logo as a gauge). I could have bought a new A-frame ($255+shipping), but instead I decided to modify my A-frame. I cut away 2" from the plate, then with the help of a neighbor we re-welded a strengthening flange back onto it. The flange was made from the piece we trimmed off the plate. This resolved the interference issue and allows the transmission to fully seat down onto the A-frame, all while retaining plenty of strength. Read the post linked above for details on the modification to the A-frame, but this is the result:

2) Driveline/Pinion Angles

Next up was the driveline angles. Based on THIS POST and THIS POST, the 3 general criteria when setting up the driveline angles are:

- Ideally, the pinion angle should be 1 degree or less

- The operating angles on each end of the driveshaft should be equal to or within 1 degree of each other and have a 3 degree maximum operating angle

- Have at least 1/2 of a degree continuous operating angle. Some definitions…

After fixing the A-frame and getting the transmission seated on the A-frame, I took measurements and found that while my pinion angle looked good, my two operating angles exceeded the 3° recommended angles. This is all captured in the A-frame post HERE. To resolve this, I ended up removing the 0.4" cylindrical spacers and washers that FFR includes with the transmission mounting hardware. After removing them, I now meet all 3 criteria above for the driveline angles. Here are the resulting numbers with some reference images of how/where I took my angle measurements. I'm happy with these so I'm calling it good:

Measurements:

- Frame: 0deg (reference)

- Engine/Trans: -1.1° sloping down toward the rear

- Driveshaft: -1.85° sloping down toward the rear

- IRS pinion flange: -0.75° sloping down toward the rear

- OA1 = 0.75°

- OA2 = 1.1°

- Pinion Angle = 0.35°

Last edited by dbo_texas; 02-23-2024 at 11:31 AM.

Reason: Updated with details of A-frame fix and pinion angle

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

02-25-2024, 09:16 PM

#172

Senior Member

-

04-08-2024, 10:59 AM

#173

Senior Member

Safety Loop Modification, Engine Lift Brackets, Triple Reservoir

Got a few hours of work in over the weekend.

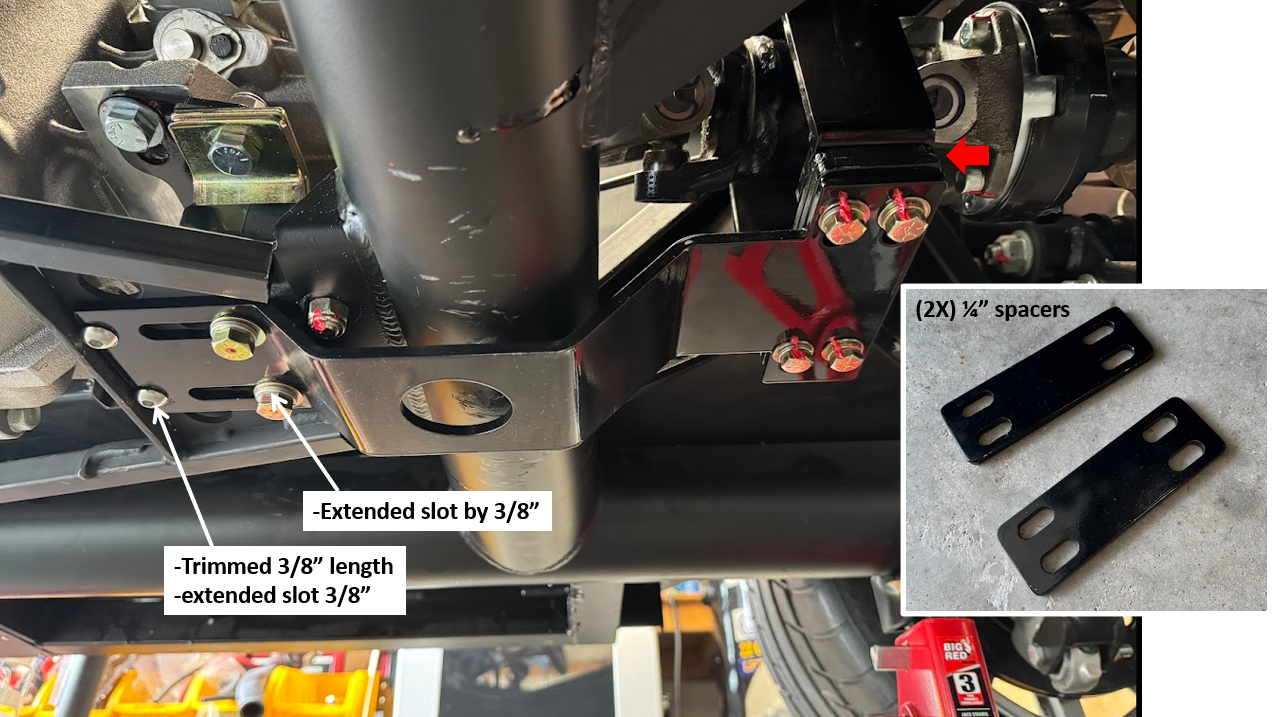

Safety Loop Modification

After the initial fitment, there were 2 changes I wanted to make. For the first, I wanted to shift the loop towards the front by about 3/8 inch to provide a little more clearance to the U-joint knuckles. To accomplish this, I needed to trim the front edge and elongate the mounting slots for the bolts. Used my angle grinder with cutoff wheel to make the long cut, then drilled new holes to extend the slots and used a Dremel cutoff wheel to clean up the slots. For the second update, I wanted to replace the washers I was using as spacers for the hoop with some solid aluminum spacers. I modeled these up in CAD then cut them on a laser cutter then painted them w/ epoxy paint. They turned out great and were a perfect fit.

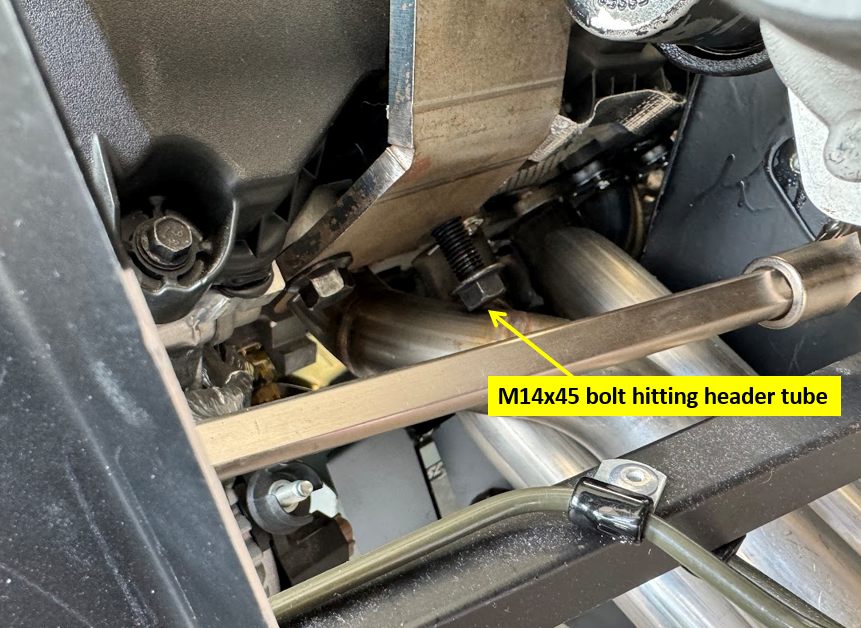

Engine Lift Bracket Removal

Next up was to remove the Coyote lift brackets. This is where I ran into some trouble. I had read on another member's forum post that they ran into a problem removing one of the bolts --> there wasn't enough clearance to the Coyote header tube to back the bolt out. Well I ran into the same problem...I was aware of this but I didn't see the post until I already had the header installed and the engine in place.

The only way to cut this was with a multi-tool, but unfortunately for my build the hydroboost and steering shaft were in the way and I couldn't get the tool in. So I removed the steering shaft and unbolted the master cylinder from the front of the hydroboost, and this just barely gave me enough access to get the multitool in there.

I must have used some high strength alloy bolts because I chewed through (2x) nitrous carbide multi

-tool bits ($35) cutting the bolt, but I finally go it.

Oil Filter Install

With the engine lift brackets removed, I went ahead and installed the low profile oil filter. I used Fram PH10060, but Mobil M1-113 or STP S10060 would also work from what I've read.

Triple Reservoir Re-Install

With the engine installed, I went ahead and reconnected my front brake lines and re-installed the triple reservoir. I had already made the mounting brackets and drilled the holes, so all I had to do was rivet the bracket onto the 3/4" frame and mount the hoses w/ hose clamps. Red hose goes to clutch, and the two black hoses go to the brakes.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

04-21-2024, 09:00 PM

#174

Senior Member

Re-mount radiator, hood hinges, expansion tank, Coyote PCM

I had a few hours of free time Saturday so decided to re-mount a bunch of the accessories. First thing I did was tighten the engine mount nuts to 60 ft-lbs. I couldn't find a spec for this but some folks on the FB page provided some recommendations in the 55-65 ft-lb range, so I split the difference.

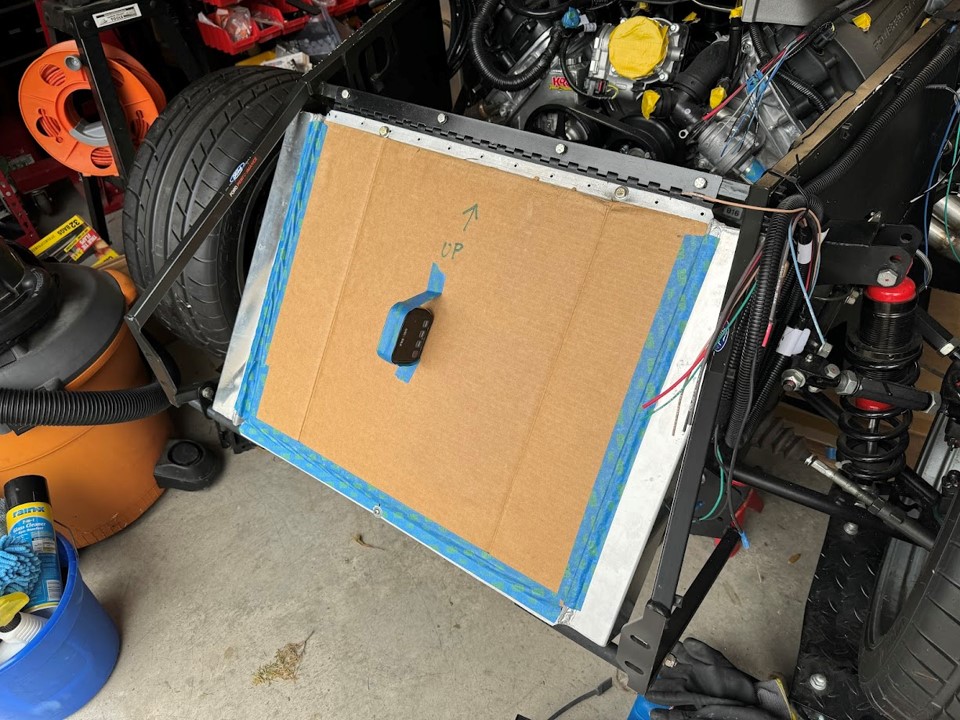

Next up, I re-mounted the radiator. This went super quick since I was already familiar with how it mounts. I zeroed my angle finder on the bottom 4in frame tube, then taped it to the radiator and mounted it at the recommended 51°. While I was at it I went ahead and riveted the Breeze upper radiator mount hinge to the radiator. I had previously left that unmounted because I was on the fence about painting the radiator black. Since I'm not going with the chrome delete aesthetic any more, I went ahead and left the radiator as-is (unpainted). Here's the result:

Next up was the hood hinges. These also went on very quickly since I've mounted them previously. I left the nuts just barely tight because I know I'll need to adjust them when it comes time to fit the hood. For now the gas struts are just tied to the 3/4 frame tubes.

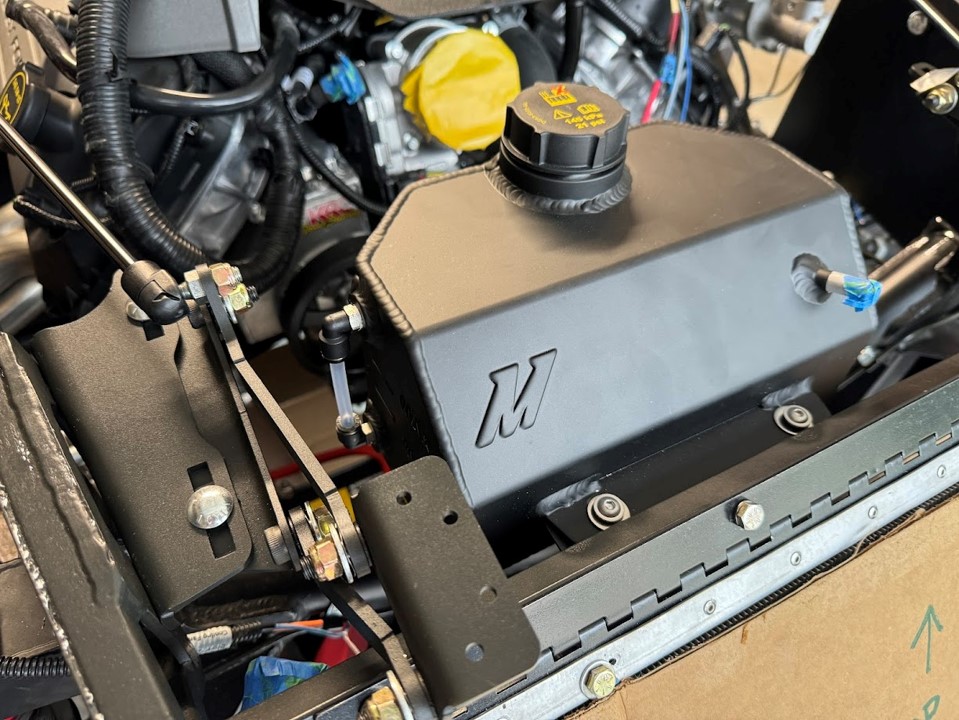

After this, I re-mounted the Mishimoto coolant expansion tank. 3 screws to mount it, and done.

I really like the sight tube on the side of this tank.

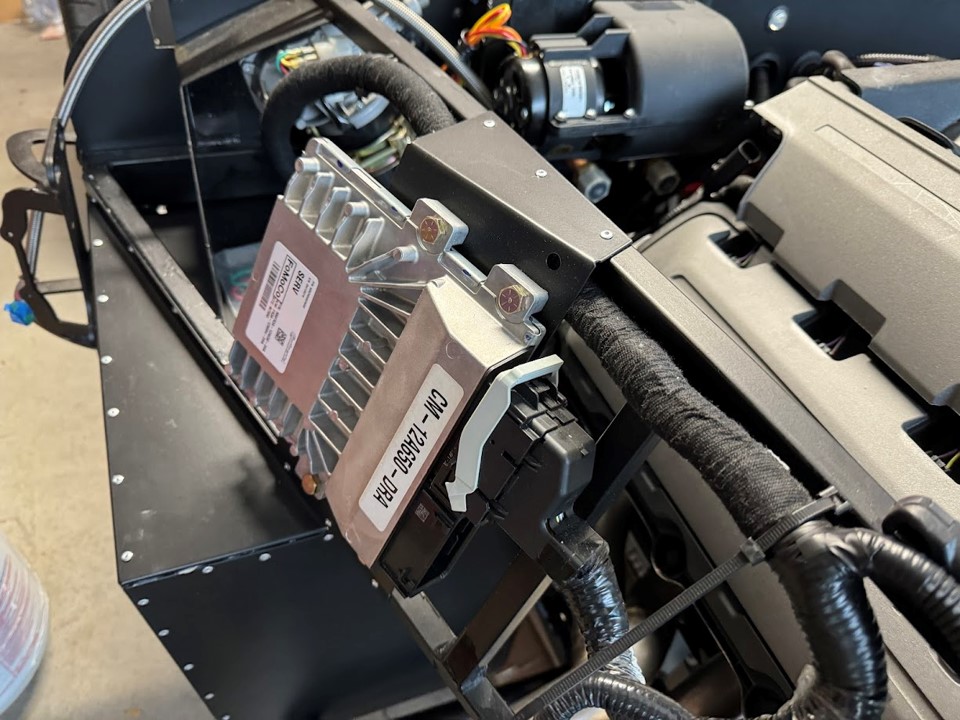

After this, I went ahead and riveted down the Coyote PCM mounting bracket to the 3/4" frame tubes. I had been holding this on with clecos but I see no reason not to go ahead and mount it.

NEXT STEP: trans tunnel shifter hole

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

04-21-2024, 09:46 PM

#175

Senior Member

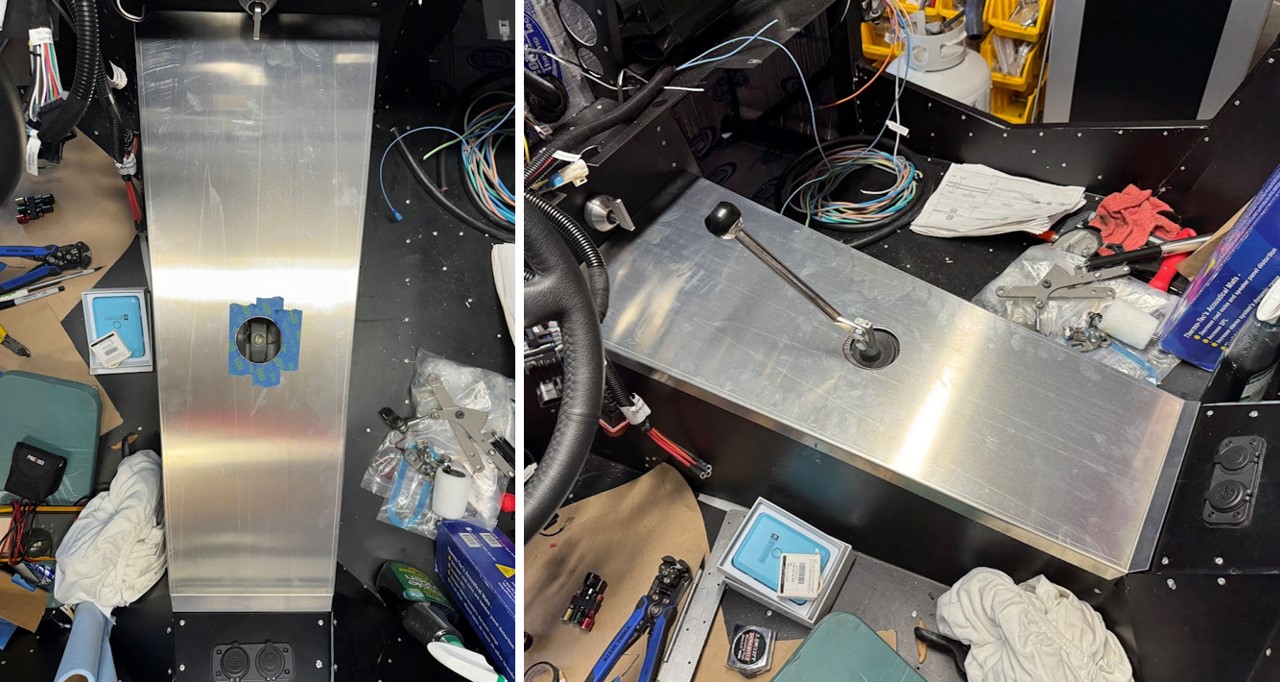

FF Metal Transmission Tunnel Shifter cutout

I've been wanting to go ahead and cut the hole the FF Metal transmission tunnel that I bought. Before I re-installed the drivetrain, I crawled under the car and traced out the 3/4" frame cross members so I had some reference points. After taking some measurements with the drivetrain installed in its final location, I marked and drilled a pilot hole where the center of the shifter is located, then drilled out a 2-1/2" hole for the shifter.

After mounting to the trans tunnel, the hole is a little off and I think I'll end up growing the size of the hole to about 3" to make sure I have plenty of room for clearance in all gears. Should be covered easily with the boot and trim ring. But otherwise looks pretty good.

I still need to figure out which cup holders I'm going with - maybe the billet ones from Eddie Motorsports (MS281-43P) and cut the holes for those. After I do that, and the E-brake final mounting, I'll send this trans tunnel top off to a local upholsterer and have them cover it with the same saddle leather as my seats and door cards.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

Probably a good starting point.

Probably a good starting point.