-

08-30-2022, 04:05 PM

#481

-

08-30-2022, 05:02 PM

#482

Scott I'm admiring your Wilwood brakes. Did you order those with your kit or source them elsewhere? Still waiting for mine...

John

-

08-30-2022, 05:34 PM

#483

Originally Posted by

JMo

Scott I'm admiring your Wilwood brakes. Did you order those with your kit or source them elsewhere? Still waiting for mine...

John

They were the 12.88" front and IRS rear drilled and slotted upgrade with the complete kit. Pictures don't do them justice. They do force you to use a 17" or 18" wheel.

-

08-31-2022, 03:23 PM

#484

-

08-31-2022, 04:47 PM

#485

Any word on header ETA? I'll be waiting on a set very shortly.

-

08-31-2022, 06:47 PM

#486

Originally Posted by

GT_Rich

Any word on header ETA? I'll be waiting on a set very shortly.

Nothing yet.

-

09-02-2022, 04:44 PM

#487

-

09-07-2022, 04:00 PM

#488

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

09-07-2022, 04:16 PM

#489

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

09-07-2022, 04:28 PM

#490

I didn't want to upset my daughter by telling her that we forgot to apply thread locker to the fasteners holding the battery box in place. She went back with her mother yesterday so today it was removed and reinstalled with blue thread locker. All of the brake lines were also rechecked for tightness. The special spacer was installed on the diff using orange thread locker and torqued by feel as I don't have the right fitting to use my torque wrench.

I finished and installed my first aluminum panel today!

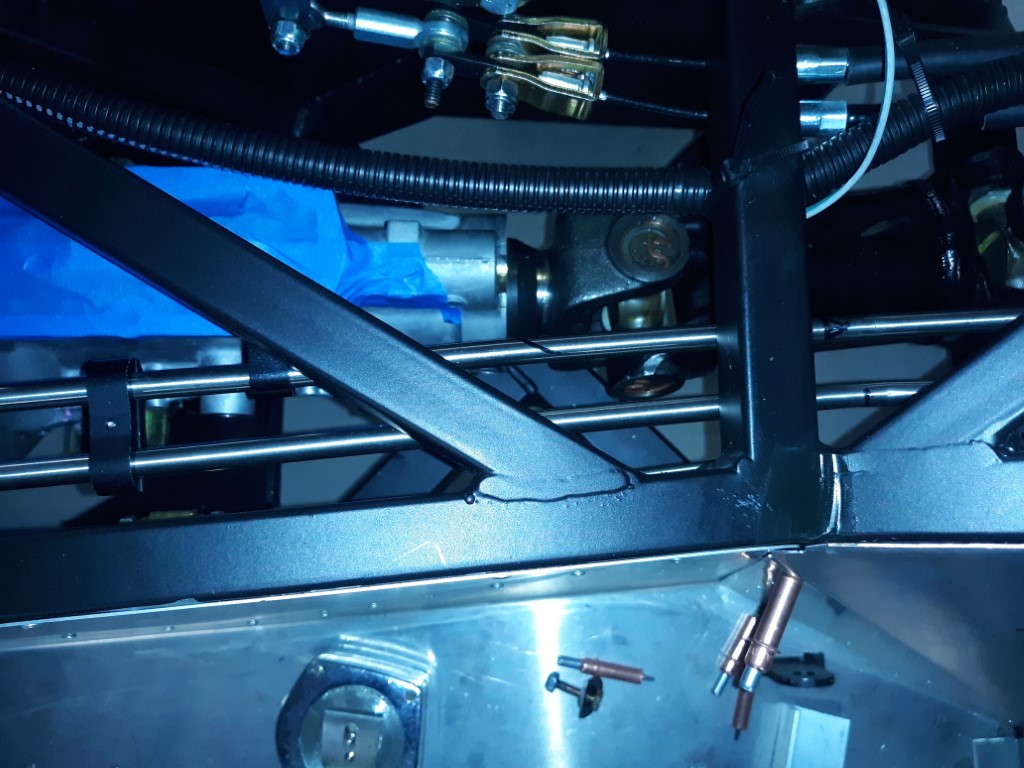

If you look close you can see the driveshaft and the safety hoop in the background. I want to get the safety hoop mocked up before I start installing the tunnel panels permanently.

-

09-08-2022, 03:54 PM

#491

-

09-08-2022, 03:57 PM

#492

-

09-11-2022, 12:41 PM

#493

-

09-12-2022, 05:38 PM

#494

Worked on a couple of the PS footbox panels I want to install permanently before I drop the engine in. Inside the footbox I am applying a layer of Dynamat sound deadener covered by a layer of Dynaliner for the heat. It will all be covered with carpet in the end. The exterior is sanded with 220 grit sandpaper using a random orbital sander followed by a coating of Shark Hide.

-

09-14-2022, 02:02 PM

#495

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

09-15-2022, 11:08 AM

#496

Senior Member

Originally Posted by

Namrups

Coupe builders heads up!!

I drilled out the rivet already installed and removed the metal filler piece. As shown the drill had already scared the serial #. By looking closely you can see that the only possible number it could be is a 3 so I hope this doesn't give me problems trying to register this car.

Unfortunately Scott, it might. I know that's not what you want to hear but I would reach out to the inspection dept and see if you can get in front of it. I am not saying it will definitely or even likely be a problem but you don't want to finish the car and find out it's an issue. Better to get in front of it first.

I know how stressful that part can be. Call the Technical Dept and ask for advice. I would consider sending pictures of the damaged frame and a picture of the Certificate of Origin to Division of Field Investigations as well depending on what the Technical Dept says.

Like I said you are probably fine but if your not better to know now.

MK4 #10008 - Ordered 10/06/20, Delivered 03/03/21, First Start 7/22/21, First Go Kart 7/24/21

Paint by Metal Morphous 5/14/22, Legally registered 6/8/22, Graduated 7/20/22

Build Thread

https://thefactoryfiveforum.com/show...been-delivered

Complete Kit, Ford 306, Sniper/Dual Sync, T5, Hydraulic clutch

-

09-20-2022, 04:52 PM

#497

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-01-2022, 08:59 AM

#498

-

10-01-2022, 09:21 AM

#499

-

10-01-2022, 09:29 AM

#500

-

10-01-2022, 09:41 AM

#501

-

10-01-2022, 09:54 AM

#502

-

10-01-2022, 09:55 AM

#503

The final issue is the fact that the cross brace on the transmission tunnel is right in the way of the shift lever. If you look close at this picture you can see that the brace is welded in the front at the intersection of the chassis members but at the rear is is short of this intersection. If they were to weld it starting at the rear intersection it would move that brace back enough to clear the shift lever. It looks like I will have to get the Sawzall out and remove that brace.

-

10-01-2022, 12:00 PM

#504

Member

There isn't the option to move the shift lever? Some trans have multiple locations?

Seems like you shouldn't have to cut things but I've heard of it.

-

10-01-2022, 12:44 PM

#505

There are 3 positions. The two easy ones are under the cross member and will depend on which way you put the shift cover on. The third one is that blank plate in front. That is a separate kit that has to be purchased and the whole rear end of the transmission has to be removed and the internals changed. Not something I would want to do if I don't have to. There is also the question of clearing the dash being that far forward. I don't plan on racing so I don't believe removing this brace will really effect anything with the car.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-03-2022, 09:02 AM

#506

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-03-2022, 09:05 AM

#507

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-03-2022, 02:54 PM

#508

I have looked at the issue of the cross brace being in the way of the shifter from every angle. I can see only 2 solutions. 1: buy the shift kit to move the shifter all the way to the front. This is not workable for me. I do not want to pull the engine out for one and I think it would be very, of not too close to the dash. 2: Cut the cross brace to clear the shifter. If anyone else has another option please feel free to speak up!

-

10-03-2022, 03:04 PM

#509

Originally Posted by

Namrups

Health update!

Had an appointment with my cancer doctor today. Good news! Good to go for another three months. Better news! Because I have done so well on the medication, my doctor has decided to try a lower dosage of the cancer meds! He believes a lower dosage will still keep the cancer at bay and reduce some of the side effects such as muscle and joint pain, hypertension and what I feel is most important the out of pocket cost! He wanted to see me after only three months just to make sure all is well. Praying this works.

Due to the fact it was over 100 degrees today I decided to put off working on the car and instead went in search of a supplier of sheet aluminum. I have ideas of parts and pieces I want to fab and didn't want to wait for online sales. I found a local business called Metal Supermarket that specializes in small orders. They had a cutoff rack that I found three pieces 20" x 22" and I ordered two specific cut pieces 23" x 7 1/2" all for $56.00. When I priced this online it was over $100.00! Great find.

Really nice to hear about your update with your doc. You must be doing something right:-) Continue with your fun agenda with this build. Maybe all will be in the rear view mirror before long!

-

10-03-2022, 03:16 PM

#510

Originally Posted by

Namrups

I have looked at the issue of the cross brace being in the way of the shifter from every angle. I can see only 2 solutions. 1: buy the shift kit to move the shifter all the way to the front. This is not workable for me. I do not want to pull the engine out for one and I think it would be very, of not too close to the dash. 2: Cut the cross brace to clear the shifter. If anyone else has another option please feel free to speak up!

I have a different setup with my SBF / TKO600, and I opted for the midshift. This may not be relevant to your design constraints. It did solve the cross member excision question for me tho. However, and there are more things in play like seat choice and steering wheel position, but in my case, it is a little crowded with the mid-shift. Short hands (or bent elbows) with both steering wheel and shifter. If wishes were fishes, I would wish for a bit more of a stretched position. But then ... I am just getting used to this layout. I may choose to design or find a different shift lever - I cheated a bit and drilled and tapped a different mounting hole in the kit lever to open it up for me a bit; perhaps not enough.

I am going to get some road time on this little beastie. Muscle memory will make all of this moot for me I expect :-)

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

10-03-2022, 03:47 PM

#511

Not a waxer

Looking great Scott! Last I knew a mid shift is not yet available for the TKX. Cut the diagonal tube and carry on…trust me, the car won’t collapse upon itself when you do

Jeff

-

10-03-2022, 03:58 PM

#512

Originally Posted by

Jeff Kleiner

Looking great Scott! Last I knew a mid shift is not yet available for the TKX. Cut the diagonal tube and carry on…trust me, the car won’t collapse upon itself when you do

Jeff

Thanks for the kind words Jeff! If I was going to race this car I would remove and then reinstall that brace in a different location but as a street car I will just cut a portion of it out of the way and move on.

-

10-03-2022, 07:17 PM

#513

Any option I come up with is going to require some welding. The purpose of the brace is to help prevent the left and right side of the tunnel from moving forward and back, independent of each other. Looking at the rest of the design, there is little chance of that happening with the brace removed, except in extreme circumstances (i.e. rolling the car for example).

It can help with some potential flexing of the left and right side of the upper tunnel., but that motion is alleviated with the attachment of the aluminum panels.

My Type 65 Coupe: Ordered May 27, 2021. Arrived November 19, 2021.

I would like to treat my gas pedal as a binary operator. It would be nice to get the cooperation of everyone in front of me.

-

10-03-2022, 08:26 PM

#514

Originally Posted by

Skuzzy

Any option I come up with is going to require some welding. The purpose of the brace is to help prevent the left and right side of the tunnel from moving forward and back, independent of each other. Looking at the rest of the design, there is little chance of that happening with the brace removed, except in extreme circumstances (i.e. rolling the car for example).

It can help with some potential flexing of the left and right side of the upper tunnel., but that motion is alleviated with the attachment of the aluminum panels.

If I roll the car, side tunnel movement will be the least of my problems! IMO removal of that bar will not be a big issue for a street car.

IMO removal of that bar will not be a big issue for a street car.

-

10-04-2022, 06:53 AM

#515

Originally Posted by

Namrups

If I roll the car, side tunnel movement will be the least of my problems!

IMO removal of that bar will not be a big issue for a street car.

I agree. I am going to have the same problem when I get there.

Slow going for me. For instance, it took me 15 minutes to install the rack, but 2 hours to move the boxes around enough to find the parts needed to install it. Then there is the one hour setup time before I can start work. It was even slower going before I bought a 10'x10' shade structure and put it up the driveway. Getting the frame into the driveway allowed me to work better and safer. Just takes time to put up and tear down the tent each day.

I just hope I can get enough done before winter sets in.

My Type 65 Coupe: Ordered May 27, 2021. Arrived November 19, 2021.

I would like to treat my gas pedal as a binary operator. It would be nice to get the cooperation of everyone in front of me.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-04-2022, 08:23 AM

#516

Originally Posted by

Skuzzy

I agree. I am going to have the same problem when I get there.

Slow going for me. For instance, it took me 15 minutes to install the rack, but 2 hours to move the boxes around enough to find the parts needed to install it. Then there is the one hour setup time before I can start work. It was even slower going before I bought a 10'x10' shade structure and put it up the driveway. Getting the frame into the driveway allowed me to work better and safer. Just takes time to put up and tear down the tent each day.

I just hope I can get enough done before winter sets in.

It's all part of the journey. I have what I feel is a good setup for this build. Have I seen better .... YES. Have I seen worse ... Yes. But we didn't start this journey because of the build space. We started this journey because of the build and the pride of "I built this!" when it's done. The trial and tribulations of your build space only shows your commitment to the journey! I for one admire that.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-04-2022, 11:40 AM

#517

Senior Member

Scott, great progress as usual! Engine looks great! And I appreciate what Skuzzy said...I spend more time finding parts and making sure I have all the correct everything on hand for 3 hours for what amounts to about 30 minutes of work on the car

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

10-04-2022, 08:16 PM

#518

New shoes arrived today!!

IT'S DONE! The cross brace has been cut and the shifter now fits!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-06-2022, 11:08 AM

#519

Need help in mounting transmission (pinion angle)

I am a real novice at this so any and all help accepted!

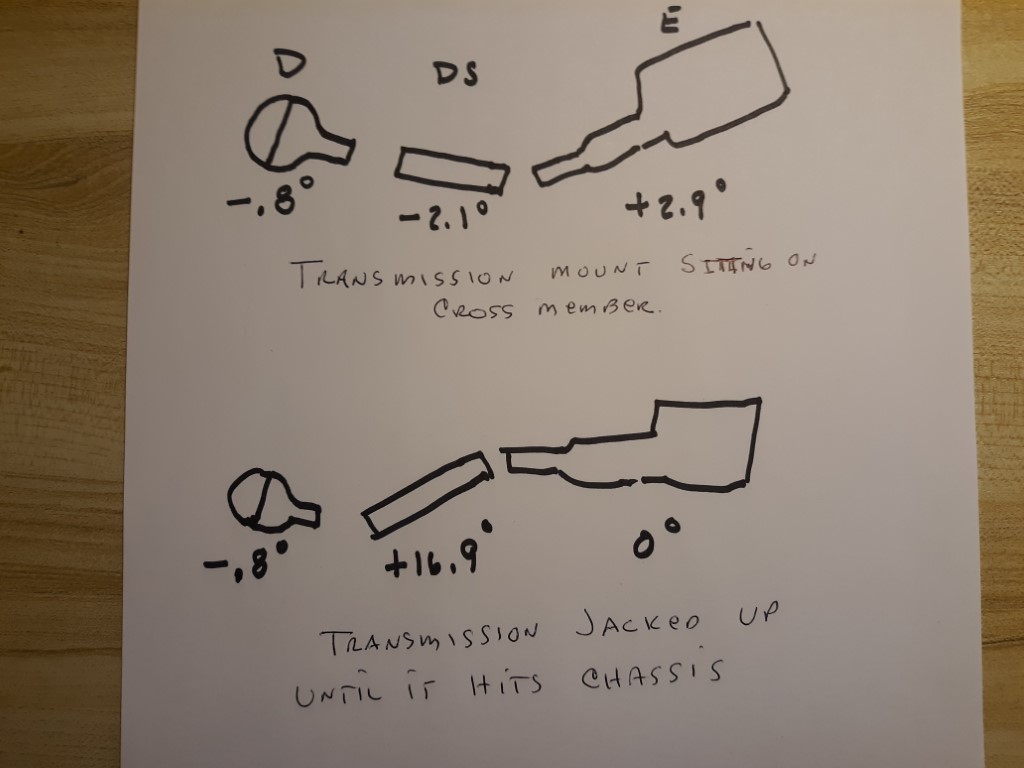

My understanding is rule 1: The angle of the output shaft on the diff should be equal but opposite to the output shaft of the transmission. In other words if the angle of the diff is a minus 8 degrees then the angle of the transmission should be plus 8 degrees. That would put the centerlines in parallel. Without going any further I fail rule 1 and now don't know what to do.

I will try to explain.

I have the IRS rear end and my assumption is the angle will never change nor can I do anything to change it. The angle of my diff is minus .8 degrees. (the output shaft points toward the ground) I measured this from the milled portion of the universal joint that is attached to the diff.

With my transmission mount sitting on the transmission crossmember my transmission output shaft measures plus 2.9 degrees. (the rear of the transmission points to the ground) This was measured from the crank pully on the front of the engine. The crank and the output shaft are in the same plane.

At this point my drive shaft measures minus 2.1 degrees. (the transmission side of the drive shaft is lower than the diff side)

In order to get the output shaft of the transmission parallel to the output shaft of the diff I have to raise the rear of the transmission until the angle reads plus .8 degrees.

When I jack the rear of the transmission as high as I can (actually hitting the chassis) the output shaft of the transmission reads zero degrees but the drive shaft now is at a plus 16.9 degrees!

I'm not an artist but here is a rough pic.

So where do I go from here?

-

10-06-2022, 04:11 PM

#520

Senior Member

First, all the angle measurements are relative. Meaning the chassis itself may not be exactly level. And likely isn't. So you're looking at differences. Not absolute numbers. Just want to point that out. For mine, the IRS diff does indeed point down slightly in relation to the chassis. Was the same on my Roadster. So I think that's a standard position by FF. In my case, no shim was required for the T-56 and Coupe mounting plate. However, plate is mounted on the bottom (vs. top as instructions show) in order for shifter to not be against the transmission tunnel cover. In that position, my pinion angle is just under two degrees. With IRS, recommended that engine is 1 - 2 degrees down from the fixed diff. So I called it good. Not much I could do to make it different. 5,100 miles (and counting) and has worked fine. No sign of any issues. You'll get different opinions on here, but many don't measure the driveshaft angle. Yes, there are design limits to how much it can move. Don't know if mine exceeds that, but hasn't been a problem. For yours, not doubting you, but seems hard to believe the driveshaft angle could change by 19 degrees by moving the engine.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

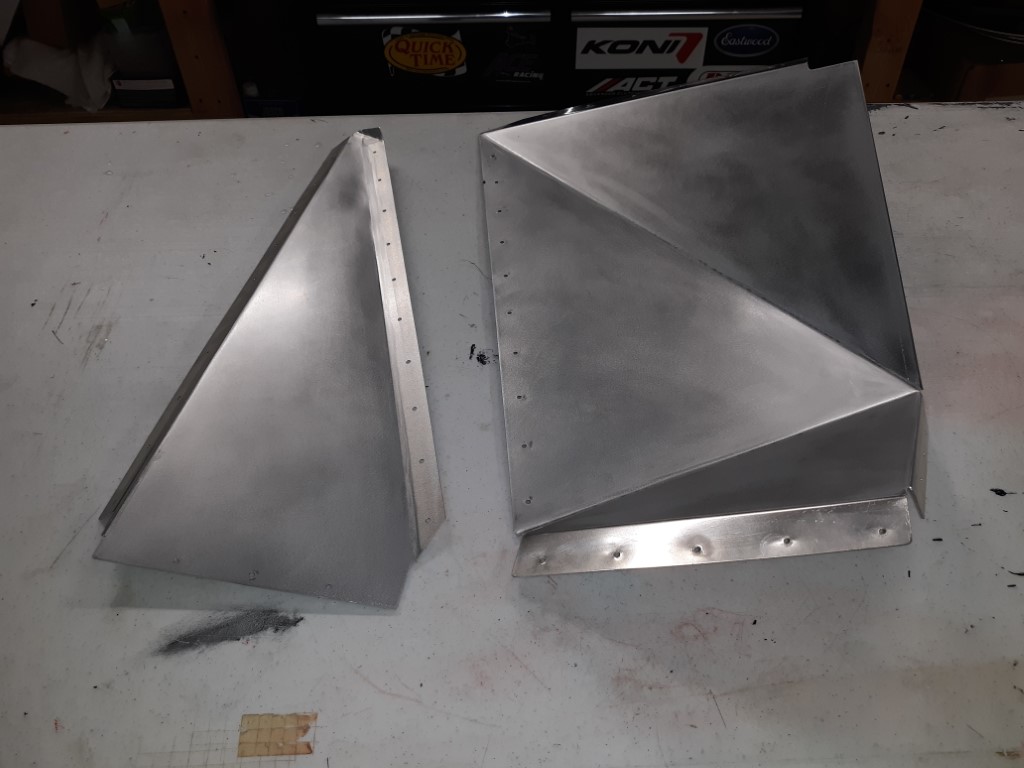

My solution to this issue was to make the tunnel cover two pieces. This will allow me to remove the lower piece without touching the upper piece. Because of having no room between aluminum and the angled chassis member I chose to rivet this piece in place when the time comes and if I have to remove it at some point I will have to drill the rivets out.

My solution to this issue was to make the tunnel cover two pieces. This will allow me to remove the lower piece without touching the upper piece. Because of having no room between aluminum and the angled chassis member I chose to rivet this piece in place when the time comes and if I have to remove it at some point I will have to drill the rivets out.