-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Senior Member

The most important value in all those measurements is the intake close event and where it lands after bottom dead center. If you think about the dynamics of an IC engine (internal combustion), as the piston sweeps past BDC during the intake stroke there's a certain kinetic energy in the intake charge that keeps flowing into the cylinder even as the piston starts its path back up on the compression stroke. If the intake cam stays open long after BDC some of that charge may end up being shoved out the intake valve. What also happens with a later intake close event is the dynamic compression ratio drops.

***Quick segue here: Compression ratio is measured statically (which is all the measurements you're typically familiar with), as well as dynamically (as in when the engine is spinning under use). In order to calculate a dynamic compression ratio you need everything for a static CR measurements, as well as the rod length and the intake close timing event.

As the piston heads back up after BDC to start the compression stroke, the dynamic compression is measured by knowing how far up the piston is from BDC and only uses that remaining cylinder volume in the calculation. The point of this allows much more aggressive cams that are better matched to your static CR.

For instance, if you have a typical 306 (just like mine) at 10:1 CR, if you do the math for dynamic CR it comes out 8.6:1. If I were to move my cam back to straight up the DCR would move to 8.47:1 but SCR stays at 10:1.

Some theoritical engine with a 12:1 SCR could easily run pump gas if you closed the intake valve at 65 degrees ABDC because that would put the DCR at a manageable 8.35:1.

What this basically means for performance is that the earlier you close your intake valve the harder your starter is going to work, the more sensitive your engine will be to pinging, and the more snappy the engine will be in the lower rev ranges. I'm only doing this because I want a lower-heavy powerband out of my engine. I will have to be cautious of the piston to intake valve clearance, but I'll cross that bridge later. If I end up with the pings (even using 93 octane) I'll have the option to move the cam back to straight up, or even retard it 4 degrees. I can even put a thicker head gasket in to lower my SCR, but then I'll lose my quench which I'm not interested in doing, but if I have to I will. The whole point of a tight quench is to increase combustion chamber turbulence to prevent pre-ignition (pings).

Back in my days of Harley engine building the rule of thumb was to keep DCR less than 9:1. That meant you could usually tune out detonation using the typical tricks without having to resort to very high octane race fuel, and the garbage Harley starters had a snowball's chance in Haiti of being able to crank the engine over without needing compression releases.

Last edited by MB750; 04-13-2022 at 03:44 PM.

-

Senior Member

-

Senior Member

Since it was obvious my OEM pushrods were too short I sacrificed two of them by making some adjustable checker pushrods. No biggie, just drill, tap, and install some longer screws that fit:

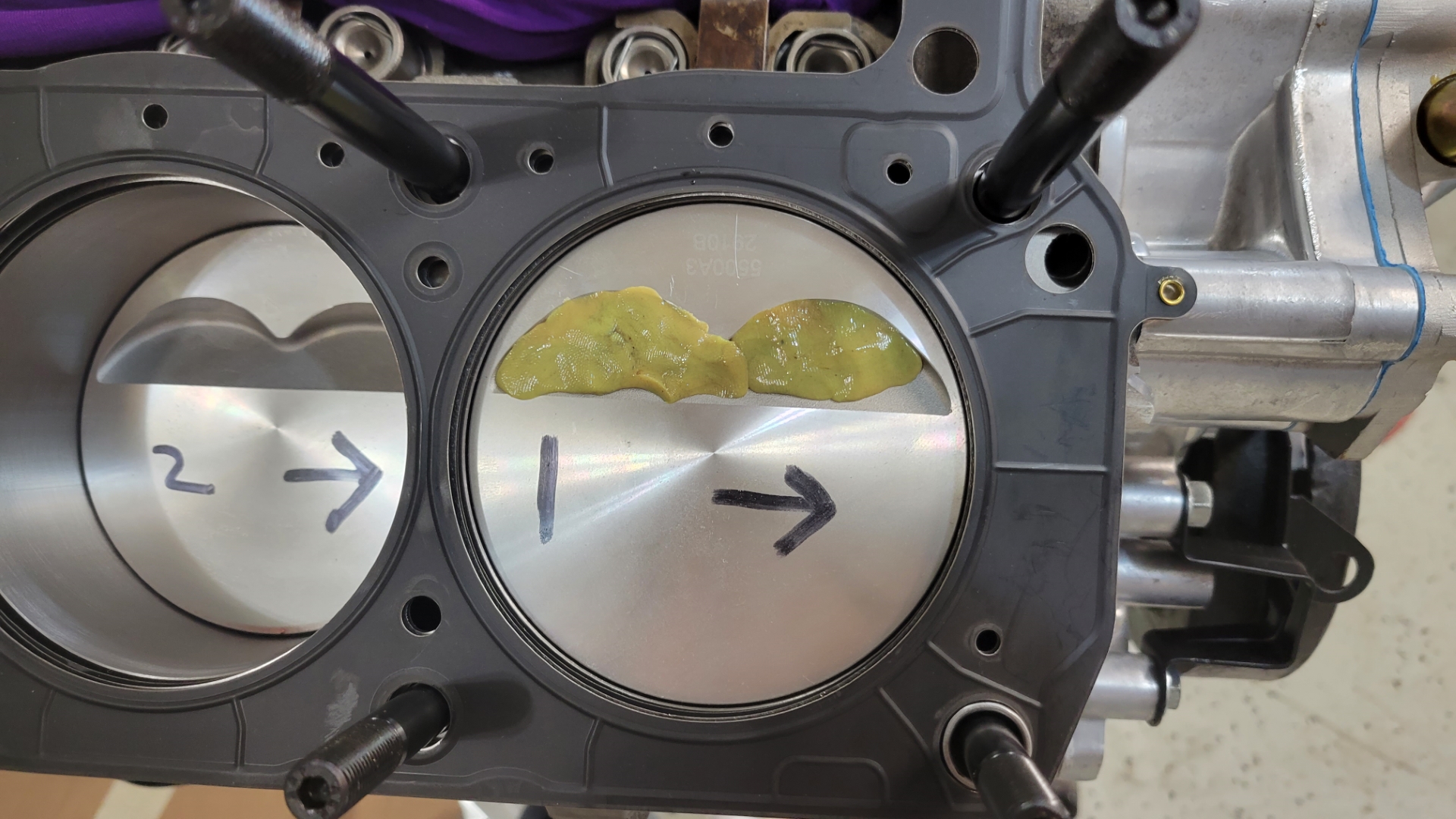

Silly putty in the valve pockets for checking clearance:

And remember that since the lifters are brand new and never been pumped up they will collapse immediately under any spring pressure. No, soaking them in oil for a week doesn't pump them up, I've tried. The only thing that pumps them up is being under pressure. I just collapse them all the way and do all my checks like they were solid lifters, then at the end figure out the travel, back that number out, and then I go buy pushrods.

Collapsing them for checking:

As you can see, the roller is not centered on the valve tip.

What's needed is to know the roller sweep during actuation. This is easy using a Sharpee. Just marker up the valve tip and spin the engine over.

As you can see, not good enough:

But on the plus side, I've got a country mile of valve clearance:

-

Senior Member

-

It's all looking fantastic... Nice work...

Last edited by BadAsp427; 05-26-2022 at 02:54 PM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

BadAsp427

It's all looing fantastic... Nice work...

Thank you. I think the worst part is I'm about a year away from firing it up, at the earliest. Depends on how fast I can get the Roadster up and rolling.

-

Senior Member

-

Senior Member

-

Senior Member

-

I hope you flipped the head gasket

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Senior Member

Originally Posted by

rustyrim

I hope you flipped the head gasket

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

I'm really enjoying watching this engine build. Good stuff

MK4 #10008 - Ordered 10/06/20, Delivered 03/03/21, First Start 7/22/21, First Go Kart 7/24/21

Paint by Metal Morphous 5/14/22, Legally registered 6/8/22, Graduated 7/20/22

Build Thread

https://thefactoryfiveforum.com/show...been-delivered

Complete Kit, Ford 306, Sniper/Dual Sync, T5, Hydraulic clutch

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

-

Senior Member

-

Senior Member

Cleaned up and painted the oil pan

Banged out the raspberries best I could. I'll run it.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Awesome work, I love your thread.

I want to point out that the drain plug in the rear of the pan will hang down below the frame rails. I have the same pan in my car (although unmodified), and plan to switch it for a 7" deep pan this winter. I figure it would be easier to consider this now rather than later. I hope this helps, not trying to be critical.

FFR MKIV 8309, FMS 306 Crate w/Edelbrock EFI, T5, 3.55 Three Link, Wilwood Brakes

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

Chopper

Awesome work, I love your thread.

I want to point out that the drain plug in the rear of the pan will hang down below the frame rails. I have the same pan in my car (although unmodified), and plan to switch it for a 7" deep pan this winter. I figure it would be easier to consider this now rather than later. I hope this helps, not trying to be critical.

Thank you, I appreciate any and all feedback. Everything I'm doing here is based on a collection of historical knowledge, and some Youtube videos, so this build is totally receptive to outside feedback because sometimes other people have a better idea how to do something than I've got planned.

Case in point, I did not know this pan's sump went below the frame rails. Once I get everything installed and moving I'll be mindful of this potential issue, but more importantly take measurements so I can modify this pan to fit better (and hold a bit more oil). I'm not a fan of the front sump anyway so a drain to the rear sump will be incorporated into the design so there's only one outlet.

-

Not a waxer

Originally Posted by

MB750

Also need to weld a plate over the low oil sensor bung

Should have asked us before doing that! It's a great place to put the oil temperature sensor.

Jeff

-

Senior Member

Originally Posted by

Jeff Kleiner

Should have asked us before doing that! It's a great place to put the oil temperature sensor.

Jeff

Ah, shucks. Initially my AEM Wideband gauge will be installed where the oil temp gauge hole is. Oh well, I could just weld a bung onto that plate when I go with an oil temp meter in the future, or put the sensor in the remote oil filter lines. That oil pan bung is a clean location though.

-

Senior Member

Got the pan installed tonight, and it was quite a PITA using those ARP studs. I had to oversize every oil pan hole just to get a decent lineup, and bend those metal bars a bit for the same reason. One hole I even needed to bust out the die grinder to oblong the hole. Lemme say, I do NOT envy whoever has to remove that oil pan.

I think this weekend I'm gonna start the paint process on the block.

-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Very nice work. After elongating the holes, you will be able to see if you need any port matching. Would not want to let this get overlooked.

Those shoulders on the upper edge of the AFR heads look like a close fit on the intake also. Maybe you will be lucky and the intake will clear.

More pics!

20th Anniversary Mk IV, A50XS Coyote, TKO 600, Trunk Drop Box, Trunk Battery Box, Cubby Hole, Seat Heaters, Radiator hanger and shroud.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

MB750

... Looks like I'm gonna need more RTV and thicker gaskets...

There's a seriously dry sense of humor at work ... I'm kinda parched now.

Super fun following your engine build. You've got an enviable set of skills, knowledge and tools on tap. Thanks for sharing.

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 1 Thanks, 1 Likes

MB750

MB750 thanked for this post

-

Senior Member

-

Senior Member

I really enjoy following your build. One thing you might want to double check is your oil pan depth, 7" deep is really the safe bet to make sure it will not be below the frame. Ask me how I know, Started with a Canton 8" and ended up with a Champ 7".

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

Fman

I really enjoy following your build. One thing you might want to double check is your oil pan depth, 7" deep is really the safe bet to make sure it will not be below the frame. Ask me how I know, Started with a Canton 8" and ended up with a Champ 7".

Thanks for the tip. I'm almost positive it'll be too deep. Someone already suggested this OEM SN-95 pan might be too deep but I don't want to stop the music just yet. I'd like to get everything installed and functional, then I'll take some measurements and do some modifying accordingly.

And keep my fingers crossed the first few thousand miles don't ground out. I plan on making the ride height a bit on the high side, depending on how it looks. I like how I can adjust that however I'd like.

-

Senior Member

-

Senior Member

Nice. You can return all that RTV and thicker gasket material now ...

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

I'm going to keep this thread updated, but I'm also going to be taking videos for the short attention span types out there:

The running trend for these videos will be summations of this thread. This thread will incorporate the details, the videos will be quick. The key is "short attention span". None of these 20 min videos with tons of red herrings all over. Straight to the key facts for the ADD/OCD viewers.

Last edited by MB750; 09-08-2022 at 02:26 PM.

Reason: Vid link

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

Fman

Fman liked this post

-

Senior Member

I also didn't cover this with pics, but I fixed how the oil pan mounts. Apparently the new timing cover wasn't perfectly exactly a replication of the OEM part because the two front oil pan bolts were juuuuuuuuuuuuuuuust a smidge angled off, which put the ends of the studs pointing away from the rest, which made installation of the oil pan and keeper rails a PITA. So I got out the die grinder and cleaned those two holes up. Now the oil pan slips on and off like buttah.

I also double-nutted the oil pan studs and used red loctite. They're studs, they ain't coming out any time soon.

-

Senior Member

Bench testing the 3G alternator that came out of the Mustang:

Edit: 6G alternator, not a 3G.

Last edited by MB750; 09-25-2022 at 06:27 PM.

-

Senior Member

Is there a reason my youtube videos are shown but not playing? I just get the spinning circle, it never starts. I can click on the Youtube link in the bottom right to go to youtube to watch it but it never plays from this thread.

-

Senior Member

Not sure if there was a time lag from when you loaded, but both worked for me by hitting the play arrow, and didn’t take me anywhere else. I think you’re good.

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

John Ibele

Not sure if there was a time lag from when you loaded, but both worked for me by hitting the play arrow, and didn’t take me anywhere else. I think you’re good.

Thanks man. The problem is on my end for some reason. I use Firefox, but when I open this thread in Edge (and don't log into my FFR Forum account) the videos play just fine.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Senior Member

Since nobody makes an alternator bracket for my application, I made one myself:

I'll paint it black later.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

)

)