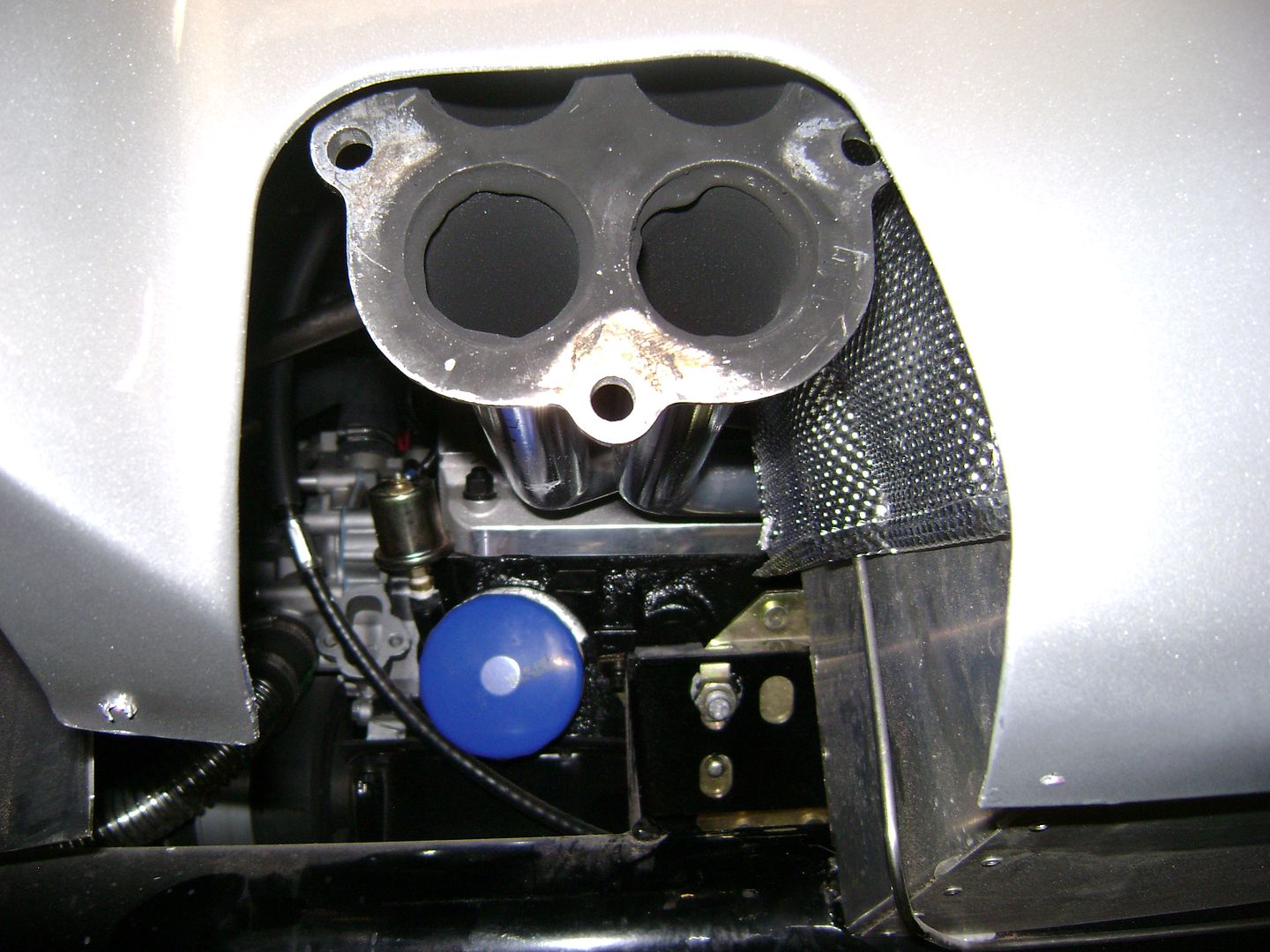

I had the exact same thing happen, but I would had to remove 2 3/4" on the drivers side. I went thru all the details with FF and what I had to do was slightly open up the holes of the mount brackets to allow the engine to drop more on the drivers side. It allowed the angle to minimize the cut, you still need to cut both sides, they are undersized from the factory but I was able to tilt the engine just a few degrees to get the angle a bit better. I went through everything you did and verified everything but in the end the only fix was to lower one side deeper into the fixed mount and boom I was done a short 6 hour fix, set the engine, lift it, open up the mount, lower, check, over and over... My car is at the painter or I would take some pictures but PMme if youwant my phone numberand we can talk it through. I only had to open up about 1 1/2" after this was all done, mostlyto keep the paint cool.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

And I can understand about fiberglass bodies needing a fair share of TLC to get right, and other minor issues like panel alignment.

And I can understand about fiberglass bodies needing a fair share of TLC to get right, and other minor issues like panel alignment.