-

Senior Member

Gen 3 Coyote Engine hoist mounting

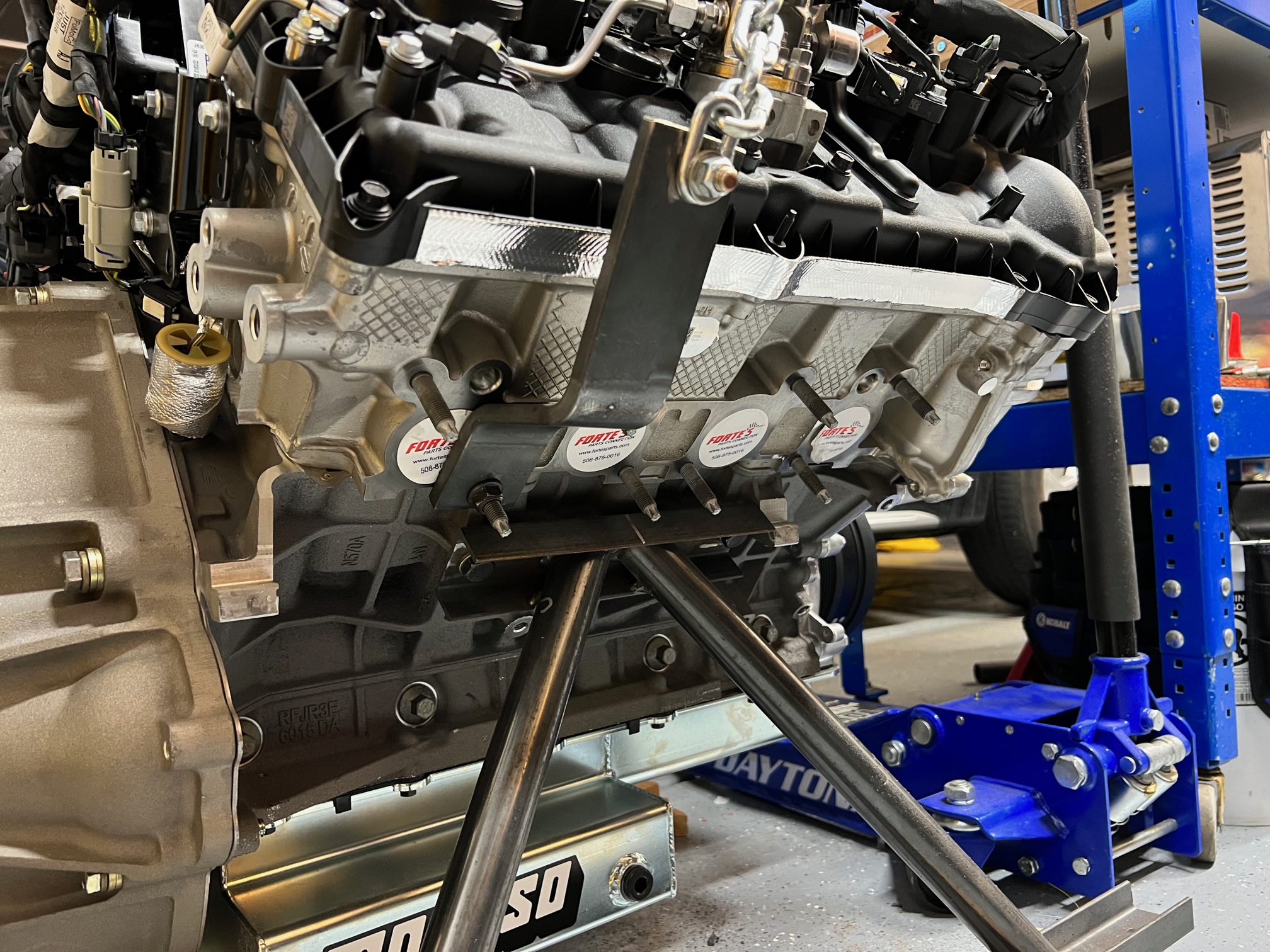

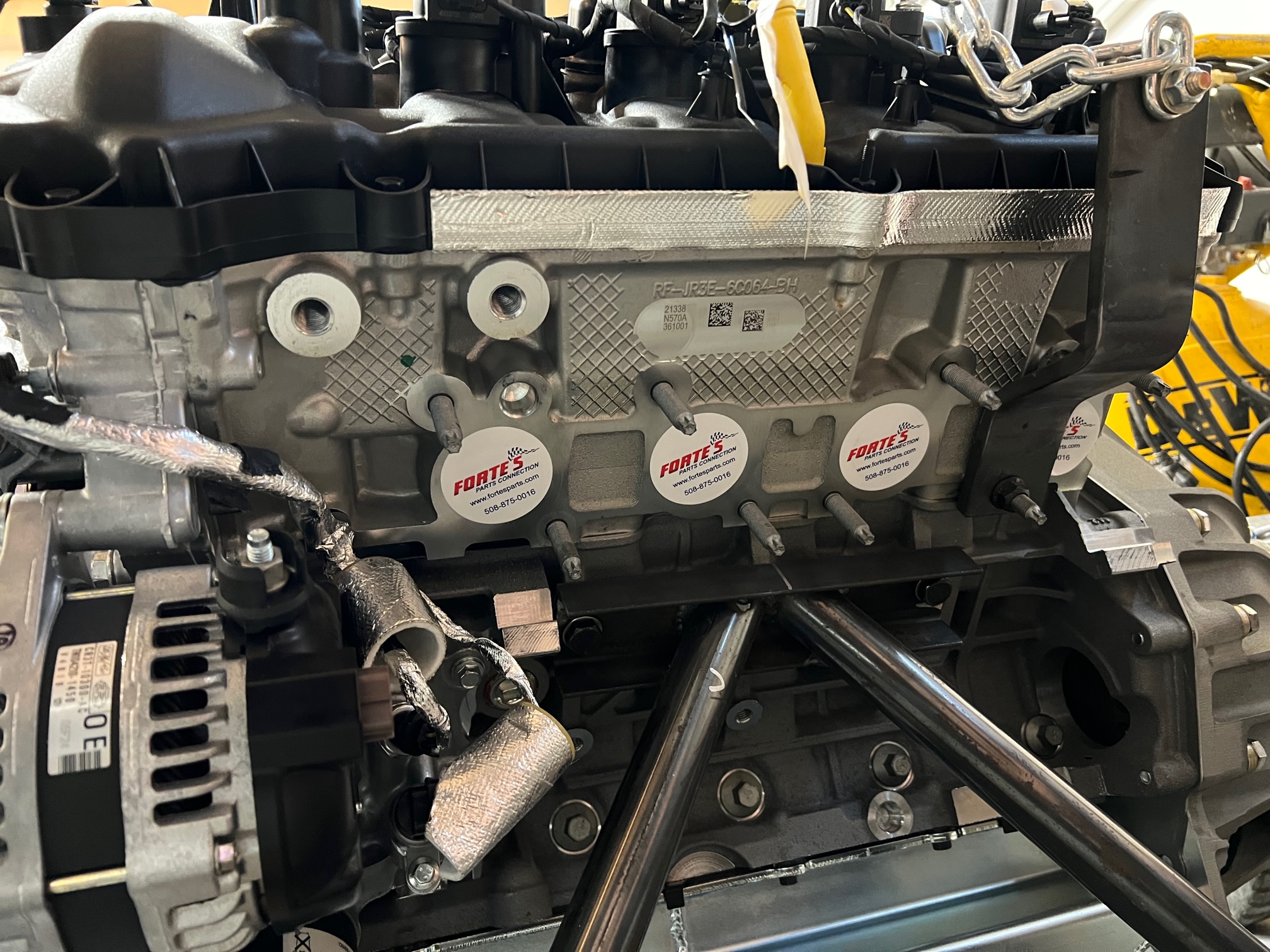

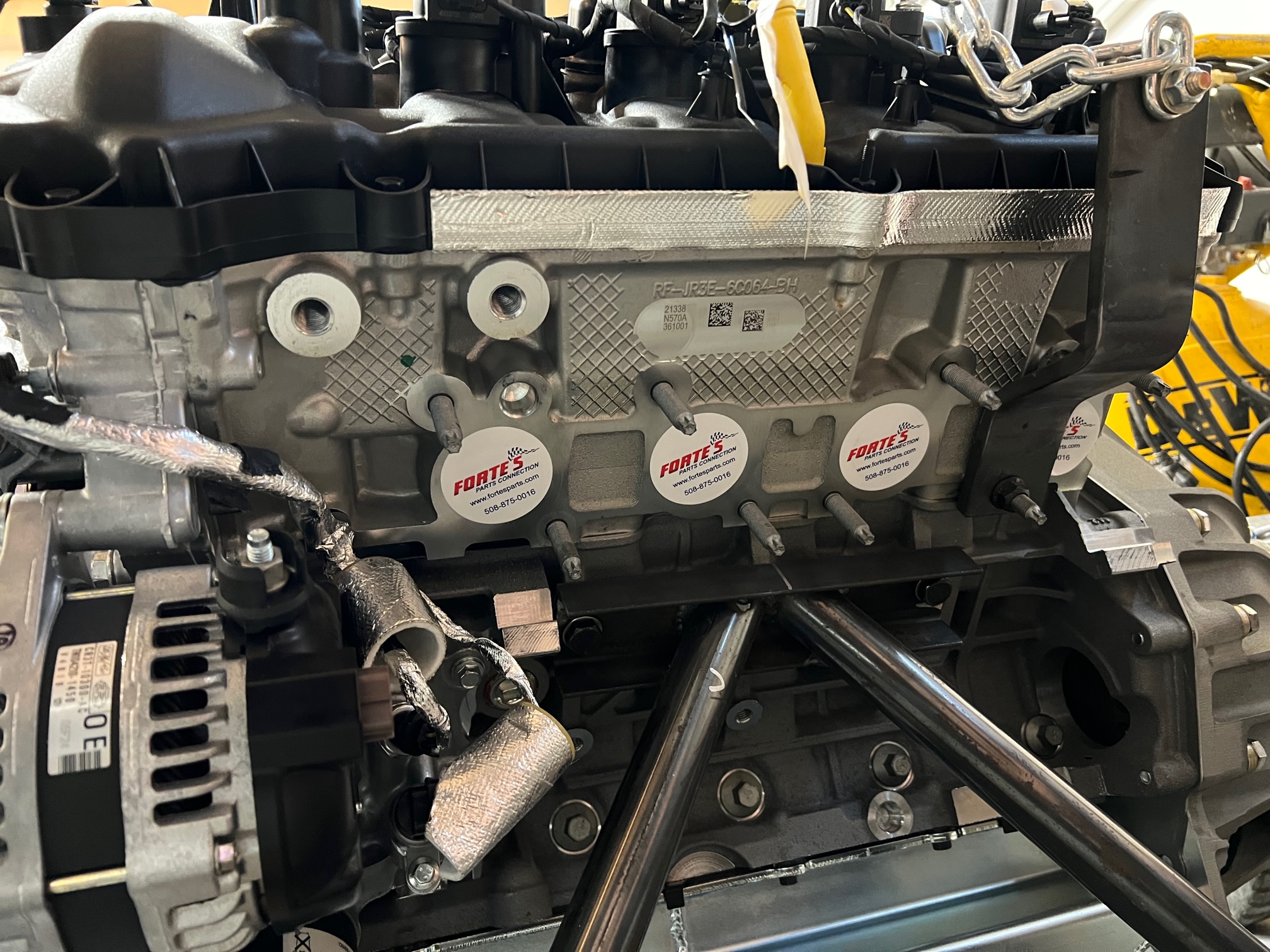

Below are pics of the current location of the engine hoist mounts as my engine came from Mike Forte. I believe there are better locations as these are both on the back of the engine (closest to the transmission). I understand its best to have one on the front and one on the back side of the engine, but I'm curious where the best lift points are? I believe for the PS they are one of the two holes immediately above the left most exhaust/header port? And on the DS potentially one of the holes right above the transmission (facing back toward the left in this photo. I appreciate any advice and experience. I'm a few weeks away from putting the engine in, so I'm starting to make sure I get the best advice!

-

Senior Member

Mike's hoist points are great for moving the engine around, but they will not allow you to get the engine in/out of the car. They're just WAY too wide. You need any of the aftermarket lifting set ups that pick up fromt he M14 points right/aft and left front.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

I am using the lift brackets from TD Motion. They mount to the left front and right rear corners of the block. I am not using them on a Factory Five but I have had no issues with them. The right rear is a bit tight on room when removing the bracket.

https://tdmotion.com/product/coyote-...lift-brackets/

MK4 base kit, 2004 Mach 1 donor, 4.6L DOHC, TR-3650 5-speed, narrowed stock axle with 3.55 gears and TruTrac, PS, PB, ABS, 17" Halibrand replica wheels, started 12/2011, registered 9/2014, sold 3/1/2018.

1970 Mustang Fastback Coyote powered Boss 302 tribute. Started 10/14/16.

Gen 3 Coupe Base Kit non-donor build. Ordered 4/5/2024 to be received August 2024.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

25th Anniversary #9772

I used one at the front driver side and rear passenger side, really helped to tilt the motor down into the cavity

https://thefactoryfiveforum.com/show...l=1#post510561

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Aside from being very bulky, Mike's lift brackets will not allow you to install the DS header while the engine is still hanging on the lift, which is slightly easier then installing it after it's sitting on the engine mounts.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

toadster

Toadster,

From those lift points, Were you able to get the headers on while the engine was still hanging from the hoist (a few inches above the engine mounts)? I hear it’s somewhat easier to install/tighten the headers while it’s in the air. Also what type of lift point brackets did you use?

Thanks,

-Bryan

-

Find someone who has a leftover set of the Factory 5 engine lift brackets. I've used them for every Coyote build we've done and they worked out perfect. We install headers after the engine is in place (with locking hardware from Stage 8) and have never not been able to get the headers installed.

20 minute, solo engine install.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

Having the right style engine hoist helps a lot too.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

i.e.427

Find someone who has a leftover set of the Factory 5 engine lift brackets. I've used them for every Coyote build we've done and they worked out perfect. We install headers after the engine is in place (with locking hardware from Stage 8) and have never not been able to get the headers installed.

20 minute, solo engine install.

You sure make dropping that engine in look easy Frank!

Thanks,

-Bryan

-

25th Anniversary #9772

Originally Posted by

Junbug

Toadster,

From those lift points, Were you able to get the headers on while the engine was still hanging from the hoist (a few inches above the engine mounts)? I hear it’s somewhat easier to install/tighten the headers while it’s in the air. Also what type of lift point brackets did you use?

Thanks,

-Bryan

while I didn't do the header install in the air, it could be done, the mount spots are away from the headers - wouldn't be an issue IMHO

-

This is what I used.

https://tomsoffroad.com/parts/coyote...iABEgLA8vD_BwE

Connected them to the Driver side front, and passenger rear. Installed the headers with the engine 2-3 inches above the mounts (don't remember exactly)

Ken

MK4 #10476, complete kit, Gen 3 Coyote, TKX with 0.68 overdrive, PS with cooler, IRS, 18" rims, dual rollbar, Carbon fiber dash,

Ordered 12/18/2021, Deliverd 9/24/2022, First Start 6/24/2023

-

Here's my revised opinion on header installation on a coyote, having had the "pleasure" of doing it multiple times now. At the time I installed the engine I followed the recommendation to install the DS header with the engine dangling slightly above its final resting place. I agree that this is perhaps slightly easier than trying to install it with the engine on its mounts and the car on the ground. But stuffing yourself under a car with the engine hanging on the hoist is, well.... a little sketchy to say the least and not something I would repeat.

Later I had to remove the original headers and replace them with new headers (with Stage8 locking fasteners), which I was able to do on my lift. Access to the DS header with the car on the lift is infinitely better than with the car on the ground, and DS header removal/installation, while tight, was definitely doable. The benefit of doing it this way is that you don't have hundreds of pounds hanging over you, suspended by a janky Harbor Freight leveler, ready to kill you. So if you have a lift I would say to save the hassle of trying to install the DS header with the engine hanging on the hoist and just do it after engine install on the lift. If you don't have a lift and will have to do the header install with the car on the ground or on jack stands then it might be slightly easier to install the DS header with the engine hanging on the hoist.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

25th Anniversary #9772

honestly the driver side bolts weren't as hard as expected, used the Stage 8 (8914) 1.25" Thread Pitch Bolt Kit for Ford Coyote 5.0 like JohnK did as well

once you're under the car with the engine on the mounts, you get creative with several wrenches and they go in really nicely

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

JohnK and Toadster,

Thanks for sharing your experience and tips. I don't have a lift, so it looks like I'll be wrestling the DS header while under the car/hoist/engine... Regarding the Stage 8 locking bolt kits, my searching has led me to two different type, 10MM x 1.25" and 10MM x 1.50". It appears Toadster used the 10mm x 1.25" based on the link above, did you install a Gen3 Coyote? JohnK I know your engine is a Gen2 Coyote, did you use the 1.25" or 1.50" kit?

Thanks,

-Bryan

-

The Gen2 coyotes used both M10 x 1.25" and 1.5" over the course of their life. Mine was 1.25". I have no idea what's on the gen3's. You should definitely verify using one of the factory exhaust studs on your engine.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

25th Anniversary #9772

yes mine is a Gen3 with the 1.25 thread pitch, they're on sale now for $49 which is a great deal - once you mount them, run a few heat cycles then put the clips on and they won't back out

they have great customer service as well

-

Member

Are the clips a PITA to remove once they set in? Just in the event you crack a header. Long term I'm sure its better than having to nut and bolt them every month.

I have some other work applications this may work for also....Thanks!

-

25th Anniversary #9772

haven't heard of any cracked coyote headers, but they're removable

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote