-

Member

Please Help With Driveshaft Installation

I have an Aluminator A52XS engine (based upon a coyote block) with a T56 transmission and IRS. The driveshaft was supplied by Factory Five based on this configuration and by all measurements it should fit. It would have been so easy to put it in place when first installing the engine/transmission. My problem is how to get it in now without removing the engine/transmission or the rear end. Both would be very problematic since I just buttoned up everything after my first start the other day (What a milestone!!!) I have tried lowering or raising the transmission but i need about another inch in either direction. I can't go lower because the transmission hits the 4" rear main cross-tube. raising it up and it hits one of the 3/4" cross-braces in the transmission tunnel. I tried loosening the bolts at the front of the pumpkin but there was no give to move it without taking the whole rear end apart. From what I can see, I may be able to get enough space if I cut and remove the middle 3/4"cross-brace on the top of the transmission tunnel. Does anyone know if removing this cross-brace will cause any problems with structural integrity of the chassis. I suspect not since I have read that some remove this brace to reposition their shifter. I can't weld a new cross-brace in place, but perhaps I can bolt something in place if it is really required. I even thought about removing the spline shaft from the driveshaft and putting it back together once it's installed, however, I think that may require a press to reinstall the universal joint on the driveshaft.

All the anxiety I had about building this monster, especially the wiring, was relieved when that engine fired right up - a truly beautiful sound. Now I'm starting to worry because I can't get a simple physical part in place.

Thanks for any help or advice you may have.

David....

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Senior Member

I know that the driveshaft for a 427/T56/IRS combo needs to be externally modified to fit, and not something that is directly done by FFR, but not sure with the Coyote.

-

Senior Member

I know that the driveshaft for a 427/T56/IRS combo needs to be externally modified to fit, and not something that is directly done by FFR, but not sure with the Coyote. I wouldn't be cutting the frame or removing the spline shaft.

-

Member

Originally Posted by

cv2065

I know that the driveshaft for a 427/T56/IRS combo needs to be externally modified to fit, and not something that is directly done by FFR, but not sure with the Coyote.

Ay idea what type of modification. The only thing I could think of that would make a difference is to make the spline shorter.

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Senior Member

Originally Posted by

DIBaledo

Ay idea what type of modification. The only thing I could think of that would make a difference is to make the spline shorter.

Not sure, but I'd give Mike Forte a call. I'm sure that he can help.

-

Member

Originally Posted by

cv2065

Not sure, but I'd give Mike Forte a call. I'm sure that he can help.

Thanks, I’ll call Mike tomorrow.

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Senior Member

Originally Posted by

DIBaledo

Ay idea what type of modification. The only thing I could think of that would make a difference is to make the spline shorter.

Do not cut the spline. Really bad idea. It's designed to have a certain amount of engagement. But shouldn't be necessary and if you're seeing an inch difference, not likely to fit anyway. Bottom line, what you describe is a sign of the wrong driveshaft length. I've done multiple builds and never had trouble getting a proper sized driveshaft installed without taking anything apart. Takes some maneuvering and wonky angles. But should go in. I see multiple builds were guys are taking things apart and eventually get it in. But that's the hard way. Check these instructions from Denny's Driveshafts (an excellent source) and see how the result compares to your driveshaft. https://www.dennysdriveshaft.com/img...iagrams/k.html

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Member

Originally Posted by

edwardb

Do not cut the spline. Really bad idea. It's designed to have a certain amount of engagement. But shouldn't be necessary and if you're seeing an inch difference, not likely to fit anyway. Bottom line, what you describe is a sign of the wrong driveshaft length. I've done multiple builds and never had trouble getting a proper sized driveshaft installed without taking anything apart. Takes some maneuvering and wonky angles. But should go in. I see multiple builds were guys are taking things apart and eventually get it in. But that's the hard way. Check these instructions from Denny's Driveshafts (an excellent source) and see how the result compares to your driveshaft.

https://www.dennysdriveshaft.com/img...iagrams/k.html

Paul,

Thank you very much. After further measuring, the driveshaft from FFR has about 1/16" of clearance. You're right, I don't think that will fit no matter what crazy angles I attack it with. I'll talk to Mike Forte tomorrow, but I think I will need to have a slightly shorter driveshaft made. You identified a link to denny's driveshafts. My engine will put out quite a bit of power and I want a top quality driveshaft to handle it. Do you know anything about their custom built products?

David....

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

I had DTS in Ionia, MI build my driveshaft. It's 5-1/4" U-joint to U-joint. The tube is only about 2" long.

https://www.drivetrainspecialists.com/

Jim

2016 Mk4 Challenge Car, IRS, 3.31 Torsen, RDI Aluminum 427w, AFR 225s, Vic Jr. ProSystems 780 HP, TKO-600 w/Liberty mods. Forward cage. Levy 6/4 piston Wilwoods. Not completed yet, will be a streetable track car.

2004 Superformance MkIII #1855, 2007 Superformance MkIII #2584 purchased in 2012 both sold.

-

Senior Member

Originally Posted by

DIBaledo

Paul,

Thank you very much. After further measuring, the driveshaft from FFR has about 1/16" of clearance. You're right, I don't think that will fit no matter what crazy angles I attack it with. I'll talk to Mike Forte tomorrow, but I think I will need to have a slightly shorter driveshaft made. You identified a link to denny's driveshafts. My engine will put out quite a bit of power and I want a top quality driveshaft to handle it. Do you know anything about their custom built products?

David....

I’ve used Denny’s Driveshafts twice. Excellent quality and I’m positive would work for you. There are other choices as some have posted.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Member

Mike Forte has saved the day....again!!! He has developed a specific yoke for this very application that will allow me to use my current driveshaft. I don't know if there is anybody with his background and creativity when it comes to the design of these cars. I don't know what state my build would be in were it not for the experts on this forum who know the intracacies of the build process and Mike Forte who has developed many solutions for some of the shortcomings of the FFR design.

Thanks to all again for your help and advice.

David....

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Senior Member

I have a Coyote (Gen2) + T56 + IRS. I have the FFR driveshaft #16038 (8-3/8") - ROADSTER 31 SPLINE 8.375" DRIVESHAFT for the 2015 IRS. I had read on several other build threads with this combo that you need to install the driveshaft during engine/trans install so it was on my checklist to do during the engine install. Once I did have it installed, I later tried to remove it (due to other issues I was trouble-shooting) and could NOT remove it completely without lifting the engine and pulling it forward so I just left it in place. This was my first time doing this type of work so its very possible I wasn't lifting/angling/moving things in the right way to get it in there, but I haven't found a single Coyote/T56 build where they were able to install the driveshaft AFTER installing the engine/trans. In fact the opposite - they all seem to recommended to install the driveshaft during the engine/trans install. I think with other combos it is absolutely possible, but maybe not with this one (in the Roadster).

Sounds like Forte has a possible solution (with different yoke) that makes this easier to install after the engine is in place. If you go that route, it would be good to share some pics of his solution so others coming behind you can benefit. Good luck!

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

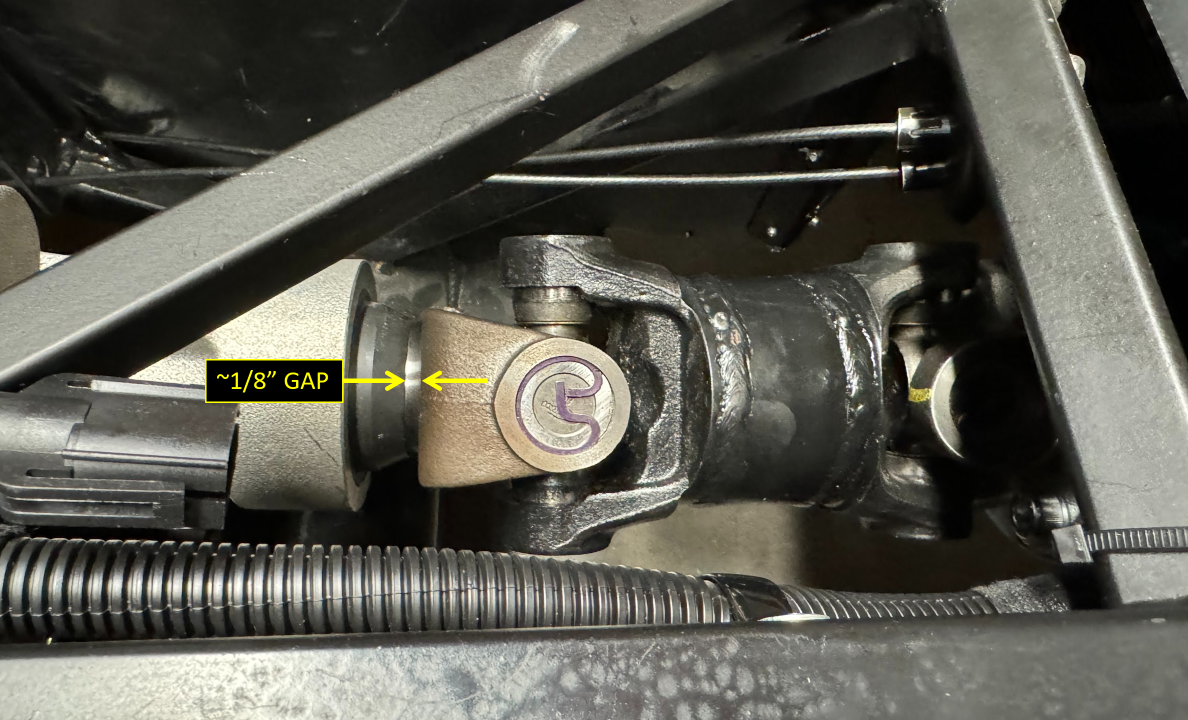

Just showing for reference my driveshaft install (#16035 - 8-3/8"). I only have about 1/8" gap from the transmission seal to the U-joint. Just shows how tight it is.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

With the trans bolted in place and lowered to sit on the 4" cross member take a bar from the top of trans tunnel move the tail of trans,( with help at bar) move the trans as far as you can to th passenger side of trans tunnel the person under the car should be able to slide the input shaft in the tail shaft. It is a tight fit but I have done this many times.

MK4 delivered 8/21/2021 completed 7/2022

complete kit, IRS, 13" brakes.

Ford performance 427 Stroker. Engine built by Russell

Quick time bell housing, .68 Tremec TKX.

FF5 17" tires and rims.

Paint and prep by Russell Hall

-

Member

This is what finally solved the problem, Mike Forte makes a yoke to substitute for the original that clamps around the forward U-joint after installation - brilliant! I now have both first start and first go cart milestones under my belt. What a feeling and the Aluminator is a true BEAST of an engine.

driveshaft 1.jpgdriveshaft 2.jpgdriveshaft 3.jpg

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Just curious, what is the red stuff on the u-joint clamps?

20th Anniversary Mk IV, A50XS Coyote, TKO 600, Trunk Drop Box, Trunk Battery Box, Cubby Hole, Seat Heaters, Radiator hanger and shroud.

-

Member

Originally Posted by

Railroad

Just curious, what is the red stuff on the u-joint clamps?

Red thread sealant. I needed to wipe off the excess, but took the picture first.

David....

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Senior Member

WAY WAY too much, should only be a small amount ON the threads

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Member

Originally Posted by

rich grsc

WAY WAY too much, should only be a small amount ON the threads

When I put it on, I thought it was only a small amount and it was on the threads. Obviously, I put too much on and have wiped it of. Can't imagine taking it off again unless there is some sort of failure.

MK4 Roadster Delivered 11/28/2022

Ford Racing Aluminator A52XS; T56 Magnum

IRS; Billet IFS; QA1 Double Adjustable Shocks; Wilwood Big Brakes from Gordon Levy

Slowly building my dream

-

Senior Member

Mike is brilliant isn't he. That isn't a new design, it was pretty common back in the day. But I haven't seen one in decades so his finding one that would actually fit for these applications is wonderful.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

That type of u-joint that mike used is referred to as a "mechanics style joint" and is very common on forklifts and other off-highway equipment, as those driveshafts are about the same length, some even shorter. I have seen some forklifts with no driveshaft tube at all, they use a 1/2" thick plate between the two u-joints, making the total length of the "driveshaft" about 3". You might actually have Hyster forklift parts in your car now! Also, a quick check for correct driveshaft length is to push the spline all the way into the transmission, then pull it out one inch. That is where it should be when installed.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote