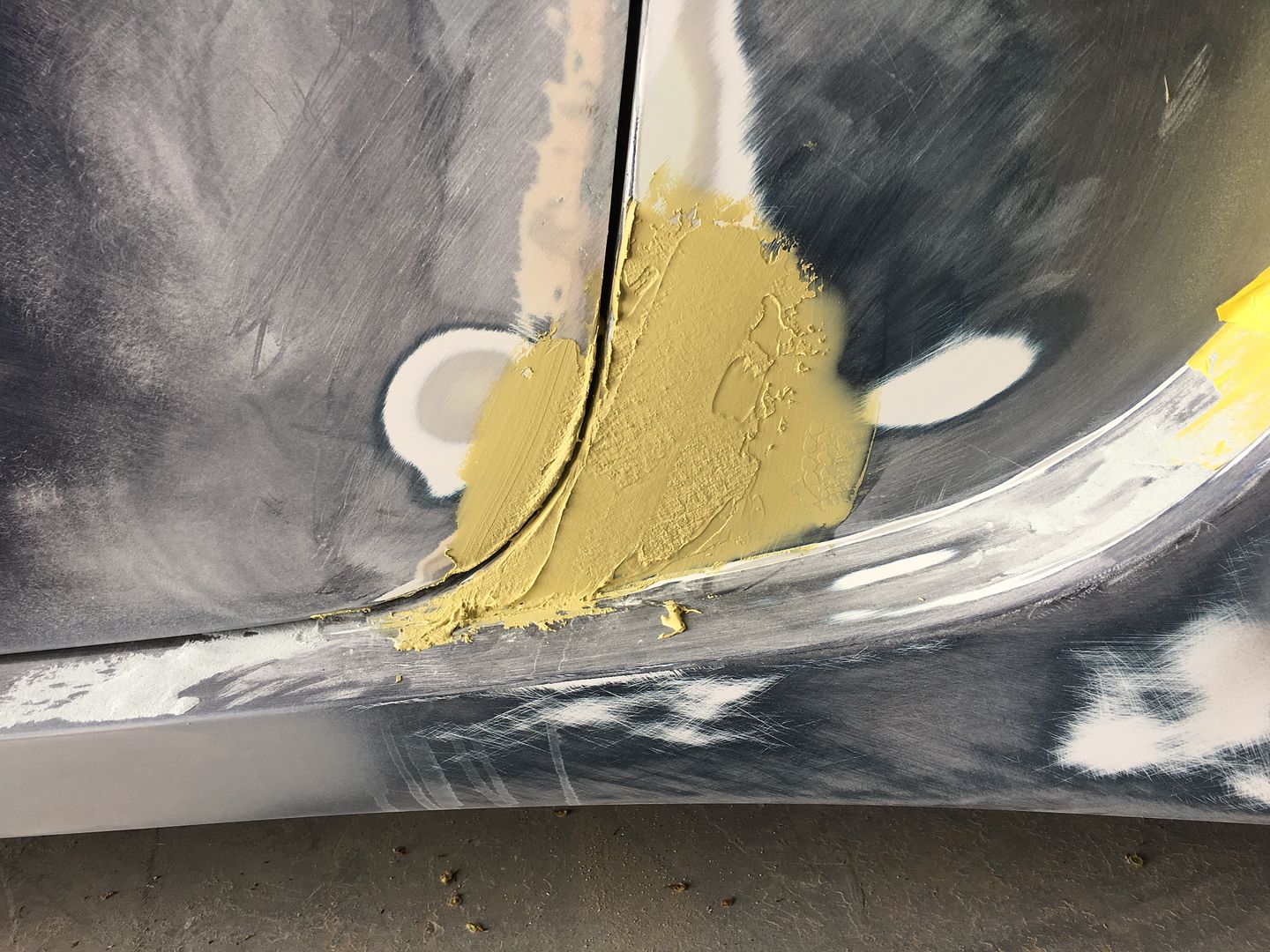

Looks like Tony's Jeep is coming along nicely. Glad to see that he is making progress on his restoration, but it really wasn't the picture that I wanted to see when I logged into his company face book site. March 4, is getting here quick. I sure don't see the car (Pandora) being done by then. There is a LOT of work that still needs to be done before this car is done. The paint on his Jeep sure looks nice though...

Mike

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

Maybe after some sleep, we'll take another look at it.

Maybe after some sleep, we'll take another look at it.

.

.